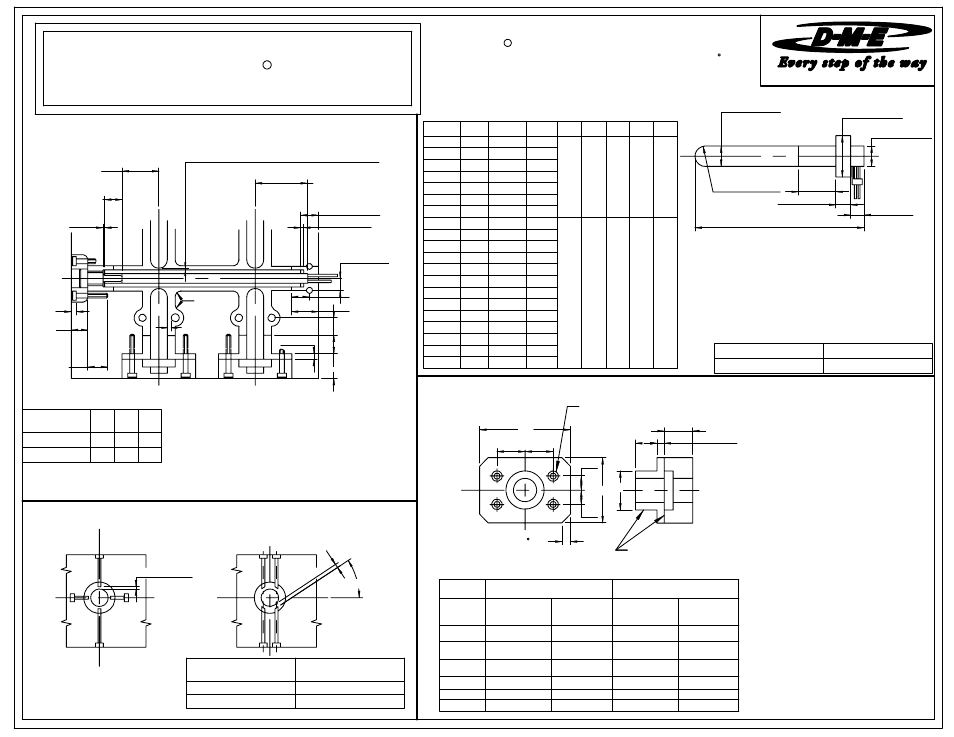

D-m-e company, Refer to mini-print no. 1700, Replacement thermocouple – DME Heaters and Auto-Fixed Integral Heater Distributor Probes User Manual

Page 2: End caps for distributor probes

Please read carefully before installing components.

ME-0725-PS-215-B 09-08 FDP/ID

INSTALLATION DATA FOR MICRO SERIES DISTRIBUTOR TUBES,

REFER TO MINI-PRINT NO. 1700

END CAP, HEATERS AND AUTO-FIXED

"INTEGRAL HEATER"

DISTRIBUTOR PROBES, END CAPS.

R

FULL RAD.

B DIA.

±0.002

E

±0.010

0.500

±0.002

C DIA.

-0.002

0.000

D DIA.

-0.005

0.000

0.50

±0.005

L

probe, but in no way alters its

MATERIAL, S-7 STEEL OR EQUIVALENT WITH 32-34 Rc HARDNESS.

AUTO-FIXED "INTEGRAL HEATER" DISTRIBUTOR PROBES

R

(240 VAC, T/C TYPE J, LEADS ARE 34" LONG AND 90 )

REPLACEMENT THERMOCOUPLE

(ALL PROBES)

NOTE: PROBE DISCOLORATION

Each Integral Heater probe sold by

D-M-E is pre-tested. This procedure

discolors the outer surface of the

performance or dimensions.

D

E

D

E

B

A

0.25 x 45 (4)

F

0.25

1.125

C

END CAPS FOR DISTRIBUTOR PROBES

2 PIECE CONSTRUCTION

DRILLED AND

C'BORED FOR

2 PIECE CONSTRUCTION

# 3/8-16 S.H.C.S

# THREAD ENGAGEMENT INTO MOLD MUST BE 1.00 MINIMUM AND TORQUED TO

25-30 FOOT POUNDS.

MATERIAL, AISI 4140 STEEL OR EQUIVALENT WITH 28-35 Rc HARDNESS

0.005 TYP.

45°

0.005 TYP.

RECOMMENDED RELATIONSHIP BETWEEN

NOTE: - S SPLIT LINE OF MOLD

L

SL

DISTRIBUTOR PROBE AND SUPPORT PINS

0.39

0.75

MIN.

1.00

MIN.

SEE

NOTE #2

0.080

±0.010

0.750

1.000

MIN.

0.250

Z

Y

X

0.562

SEE

NOTE #3

0.093

0.25 MAX

2.187 MIN.

2.750 MAX.

SEE NOTE #1

0.093

0.750

MIN.

1.187 MIN.

1.750 MAX.

SEE NOTE #1

0.080 PLUS DISTRIBUTOR PROBE EXPANSION

ON ALL DISTRIBUTOR PROBE INTERSECTIONS

0.250 RAD.

0.250 RAD.

TYP.

TYP.

MICHIGAN 48071 USA

1-800-626-6653

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

www.dme.net

D-M-E COMPANY

Note: Dimensions shown in Inches.

X

MIN.

Y

MIN.

Z

MIN.

PROBES, INTERSCTIONS AND END CAPS

RECOMMENDED RELATIONSHIP BETWEEN HEATERS,

0.394 DIA.

0.788 0.500 1.375

0.625 DIA.

1.250

between dowel pin and end cap centerlines is recommended

3. The use of (2) 0.250 dia. dowel pins with 0.562 distance

(Solid Block Distributor System only).

to secure end cap into mold

evenly and torqued to 25-30 foot pounds.

Split Plate Distributor System) Screws must be tightened

-mended to secure end caps to mold. (Solid Block and

with 1.00 minimum thread engagement into mold is recom

2. The use of (4) 3/8-16 hardened socket head cap screws

will not be centered in distributor tube.

1. Due to the longer no heat section atthe Lead end, heater

NOTES:

0.875 1.375

FDP0017 8.500

0.009

670

FDP0018 9.000

0.009

705

FDP0019 9.500

0.010

745

FDP0020 10.000

0.010

785

+0.010

2.000

1.98

B

-0.000

+0.010

2.500

2.49

-0.000

+0.010

2.000

1.98

A

MACHINING

0.625 DIA.

PROBE

DISTRIBUTOR

0.625 DIA.

MACHINING

0.394 DIA.

PROBE

DISTRIBUTOR

0.394 DIA.

DIM

ECP0006

ECP0003

CAT. NO.

-

0.875

-

0.500

F

0.375

0.375

0.221

0.625 DIA.

0.139

0.394 DIA.

48"

TC-9900

LEAD LENGTH

CATALOG NUMBER

X

PROBE

DISTRIBUTOR

0.437

0.437

E

0.875

0.875

0.656

0.656

D

-0.000

+0.001

1.125

1.124

-0.000

+0.001

0.875

0.874

C

-0.000

+0.010

2.000

1.98

-0.000

CAT.

NO.

L

EXPAN-

SION

WATTS

A

B

C

D

E

FDP0001 3.500

0.004

175

0.394 0.384 0.740 0.394 0.750

FDP0002 4.000

0.004

200

FDP0003 4.500

0.005

225

FDP0004 5.000

0.005

250

FDP0005 5.500

0.006

275

FDP0006 6.000

0.006

295

FDP0007 6.500

0.007

320

FDP0008 4.000

0.004

315

0.625 0.615 1.240 0.625 1.125

FDP0009 4.500

0.005

355

FDP0010 5.000

0.005

395

FDP0011 5.500

0.006

430

FDP0012 6.000

0.006

470

FDP0013 6.500

0.007

510

FDP0014 7.000

0.007

550

FDP0015 7.500

0.008

590

FDP0016 8.000

0.008

630

DISTRIBUTOR

PROBE