D-m-e company, Gate-mate nozzle assemblies, Installation data – DME Gate-Mate Nozzle User Manual

Page 2: Gmb9999, Please read carefully before installing components, Jumbo gate-mate machining dimensions, Mini gate-mate machining dimensions

MICHIGAN 48071 USA

1-800-626-6653

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

www.dme.net

D-M-E COMPANY

(non-magnetic).

WIRING INFORMATION

Square Coil and cast-In heaters are supplied with

2" prestripped 42" long leads. Heaters are 240 VAC

(120 VAC square coil heaters are available on request).

2 power leads are MULTI COLOR

1 ground lead is GREEN.

Thermocouples are "J" Type.

Thermocouples are supplied with 40" leads.

1 T/C lead is WHITE and negative (-) constantan

1 T/C lead is BLACK and positive (+) iron (magnetic).

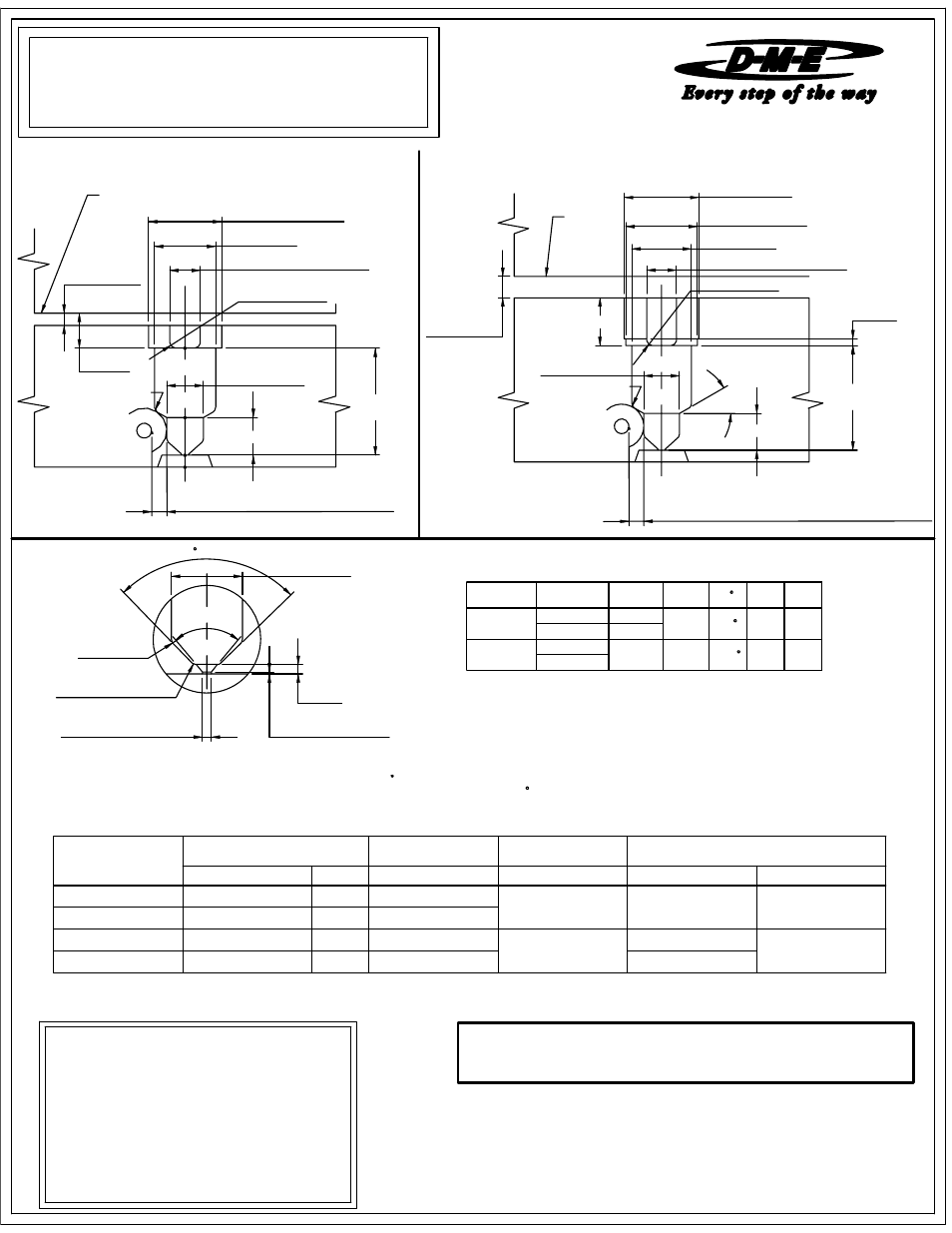

J INCL

80°

INCL

B

0.0000

+0.0005

DIA.

K RAD.

0.005 LAND (MAX.)

0.030

TO SUIT

M MIN.

0.187 SPH. RAD.

0.140

1.0625

0.125 RAD.

0.625 WIRE CHANNEL

2.000 DIA.

B

0.0000

+0.0050

2.750 DIA.

2.626

0.000

+0.001

DIA.

1.000

0.31 MIN. DISTANCE BETWEEN WATERLINE

AND DROP

0.250 MIN.

0.750 MAX.

30°

"A" + BE

SEE NOTE

MANIFOLD

LINE

0.125 RAD.

0.125 RAD.

0.625 WIRE CHANNEL

1.250 DIA.

0.7500

0.0000

+0.0005

1.501

0.000

+0.001

DIA.

0.400

0.31 MIN. BETWEEN WATERLINE

AND DROP

0.250 MIN

0.500 MAX.

0.6250

"A" + BE

SEE NOTE

MANIFOLD

0.125 RAD.

LINE

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

Note: Dimensions shown in Inches.

118

90

NOZZLE

EHR0155

TCG0100

225

ME-0739-PS-310-D

GMB9999

factor. In some instances it may be necessary to obtain an empirical factor.

SCH0004

GMB0118

TC-0002

0.125 0.030

GMB0118

then be added to the nominal "A" dimension. Formula for determining this expansion is as follows:

NOTE: The expansion factor must be taken into consideration prior to machining for, and installing nozzle. This factor (BE) must

GMB0120

JUMBO

DIM.

M

1.375

RAD.

BE= 2.500 x 0.00000633 x (500 - 68) = 0.0068.... thus "A" + BE will be 2.5068.

0.375

GMB0110

J

K

0.070

GMB0119

2.500

MINI

JUMBO GATE-MATE MACHINING DIMENSIONS

Please read carefully before installing components.

DIM.

B

DIM.

A

GMT0101

N/A

09-08

225

CAST-IN

0.6250

GMB0110

WEAR RESISTANT #

EXAMPLE: Given a 2.500 Inch "A" dimension, with a nozzle setpoint temperature of 500

F).

Please note that the above information is given as an example. Variations may occur based on mold configuration and cooling

GATE-MATE NOZZLE ASSEMBLIES

STANDARD

GMT0100

STYLE

CATALOG

NUMBER

BE= "A" dimension x 0.0000633 x (nozzle setpoint - 68

F.

MINI GATE-MATE MACHINING DIMENSIONS

INSTALLATION DATA

# # INCLUDES INSTALLATION / REMOVAL WRENCH

# WEAR RESISTANT TIP IS RECOMMENDED FOR ABRASIVE MATERIALS.

3.500

1.2500

SUB-ASSEMBLY

REFERENCE

SQUARE COIL HEATERS

(240 VAC) # #

THERMOCOUPLES

(40" LEADS)

SEAL RINGS

(PKG OF 4)

SUB-ASSEMBLY TIPS

CATALOG NUMBER

WATTS

CATALOG NUMBER

CATALOG NUMBER

CATALOG NUMBER

STYLE

GMB0120

SCH0001

800

TC-0001

EHR0001

GMT0004

GMT0006

GMT0007

STANDARD

WEAR RESISTANT #

THRU HOLE

GMB0119

SCH0002

600