D-m-e company, Installation data front load square coil heater, Important safety information – DME Front Load Square Coil Heater User Manual

Page 2: Danger warning

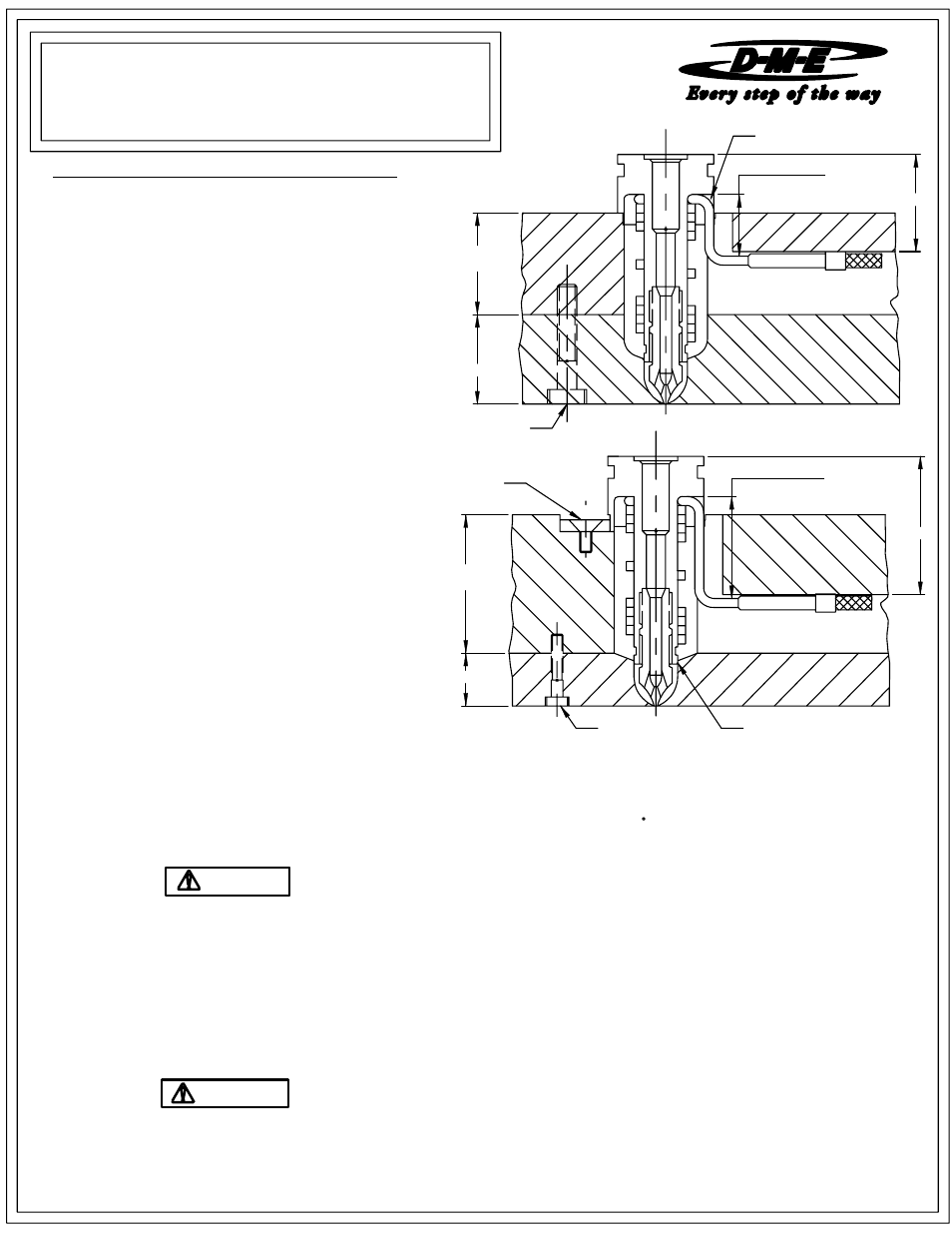

1.375 "B" DIM.

1.750

1.875

NOZZLE PLT.

"A" PLT.

OPTIONAL KEY

MOLDER TO

SHCS

SUPPLY

SEAL-OFF AREA RELIEF

DANGER

WARNING

out residual moisture before applying full power. Failure to do so may cause

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn. This product

has heated surfaces. Use caution when operating and servicing the system

to avoid severe burns. Proper protective equipment should be worn.

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it can cause fire, severe

injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

damage to this product.

US 800-656-6653

CANADA 800-387-6600

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

www.dme.net

D-M-E COMPANY

.875 "B" DIM.

1.250

1.375

NOZZLE PLT.

"A" PLT.

RELIEF SLOT

SHCS

installing and/or removing heater.

Please read carefully before

RECOMMENDATIONS AND GUIDELINES

INSTALLATION DATA

FRONT LOAD SQUARE COIL HEATER

SCH9999

ME-0741-PS-778-B

The nozzles are supplied with a Square (Flat) Coil Heater.

OPERATING PROCEDURE

c. Rotate Tube "A" counterclockwise while at the same

heater.

the angle of the Tube mates with the last coil of the

b. Insert tube "B" with angle cut within Tube "A" so that

lead lies within the slot of the tube.

a. Place heater within Tube "A" so that the bending exit

as follows:

removed. The heater can be installed on the nozzle body

nozzle plate with manifold secured in place and "A" plate

4. After the nozzle has been located and positioned in the

split on the parting line.

socket head cap screws are exposed when the mold is

3. Nozzle plate must be designed so that the heads of the

interpolation.

head to match the flat on the nozzle's head or by circle

coil heater. This may be done by making a key for the

it from rotating upon installation of the front load square

2. The nozzle head must be held in such a manner to keep

with Gate Mate 4 Nozzles only.

1. Front Load Square Coil Heaters are designed to be used

6. Secure wires in wire channel with straps before assembling "A"

plate to mold.

08-08

Female Cat. No. 18RA-2577

Male Cat. No. 18RA-251T

disconnects.

* Leads may be spliced using Thomas & Betts nylon insulated

time rotating tube "B" clockwise. This action will

channel for ease of heater replacement.

5. The power and thermocouple leads may be spliced in the wiring

the relief of the seal-off area. (see figure above).

e. Positon heater so that the end of the last coil is above

nozzle's head.

the heater exit lead within the relief slot in the

d. Slide the heater onto the nozzle body shaft aligning

the shaft of the nozzle body.

spring open the coils enough to slide the heater onto

of DME Company.

Step Smart ®, Smart Start ® and DME ® are all registered trademarks

The voltage and wattage of each heater is clearly marked on the heater tag.

It is essential to use controllers with the proper voltage and wattage capabilities.

or other heater warm-up circuitry will change automatically.

Controller equipped with Step Smart ® , Smart Step ®

Make sure you maintain this start-up setting for 15 minutes.

In either case this procedure will allow the heater to dissipate any moisture.

F if using closed loop automatic type.

loop manual type or to 200

When starting the nozzle, set the temperature to 10% voltage if using in open

iron (magnetic).

1 T/C lead is BLACK and positive (+)

constantan (non-magnetic).

1 T/C lead is WHITE and negative (-)

Thermocouple is supplied with 36" leads.

Thermocouple is "J" Type.

1 ground lead is GREEN.

2 power leads are Multi Color.

(120 VAC heaters are available on request).

36" long leads. Heaters are 240 VAC.

Square Coil Heaters are supplied with 2" prestripped

WIRING INFORMATION

optimumTemperature Control.

It is recommended to use a D-M-E closed loop Temperature Controller for