D-m-e in2 innovative interlocks, Machining & installation instructions, Insert installation – DME IN2 Interlocks User Manual

Page 2: Insert removal

Machining &

Installation

Instructions

D-M-E IN2 INnovative INterlocks

INSERT INSTALLATION

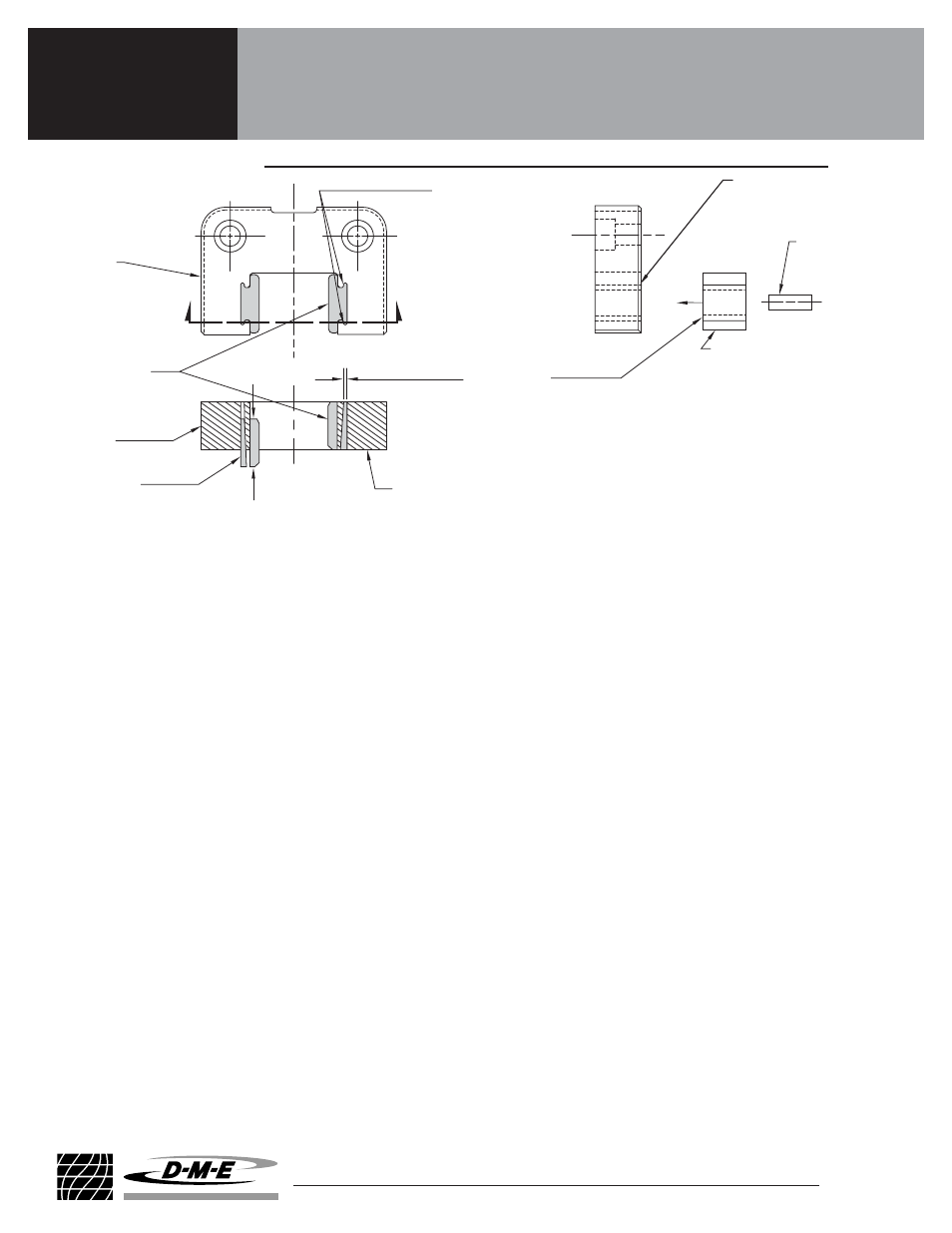

FEMALE

INTERLOCK

INSERT

INSTALLED

THIN END OF

TAPERED WEDGE

GOES IN FIRST

TAPERED

WEDGE OF

INTERCHANGEABLE

INSERT

INSERT BEING

ALIGNED FOR

INSTALLATION

ALUMINUM

ROD

BACK OF

FEMALE

INTERLOCK

Z

Z

FEMALE

INTERLOCK

INSERT

PARTIALLY

INSTALLED

SECTION Z-Z

INSTALL

INSERT

REMOVE

INSERT

BACK OF

FEMALE

INTERLOCK

INSERT INSTALLATION

D-M-E INterchangeable INserts can only be installed from

the back of the female IN2 INnovative INterlock. The back of

the female interlock mounts against the mold (and is the side

opposite the counterbores for the socket head cap screws).

When the Interchangeable Inserts are properly inserted into

the female interlock they will be retained by the tapered

wedge of the Interchangeable Insert and the retaining taper

of the female interlock. Once installed in a mold, the mold will

insure that Interchangeable Inserts will be securely retained.

1. First, place the female interlock face down on a flat

surface with the back facing up.

2. Next, select a pair of IN2 INterchangeable INserts for

the appropriate size interlock for insertion into the female

interlock. Interchangeable Inserts of the same size are

truly interchangeable; any Interchangeable Insert of the

proper size can be inserted into the female interlock.

3. Inspect the tapered wedge on the Interchangeable

Insert to determine which end of the Interchangeable

Insert is the thin end of tapered wedge. The thin end

of the tapered wedge will be inserted into the female

interlock first (refer to above drawings for clarification).

4. Insert the thin end of the tapered wedge into the female

interlock from the back and slide the Interchangeable

Insert firmly into the female interlock. The Interchangeable

Insert should seat most of the way into the female interlock

by hand. The tapered wedge of the Interchangeable Insert

provides a slight interference fit with the retaining

wedge of the female interlock.

SIS-9999-3/05

ME-E09-0199-A

5. Now, place an aluminum rod against the Interchangeable

Insert and use a hammer to tap on the aluminum rod to

move the Interchangeable Insert until it is flush with the back

of the female interlock. Properly seated Interchangeable

Inserts will be .000 to .005 below the back surface of the

female interlock. Use an aluminum rod whose diameter is

small enough to make contact with only the Interchangeable

Insert and does NOT contact the small retaining wedges

on the female interlock.

6. Repeat this procedure for each insert.

7. The D-M-E IN2 INnovative INterlock is now ready

for installation on your mold. Please carefully read

instructions on other side regarding installation of

IN2 INnovative INterlocks on your mold.

INSERT REMOVAL

To remove an Interchangeable Insert from an IN2 INnovative

INterlock, the female interlock must be removed from the mold.

1. Place the female interlock on two aluminum blocks with

the front facing up. (The front face of the female interlock

is the side with the counterbores.) Position the two aluminum

blocks under the outer edges of the female interlock but

not under the Interchangeable Insert being removed.

2. Place an aluminum rod on the Interchangeable Insert and

use a hammer to tap on the aluminum rod. The Interchangeable

Insert has a tapered wedge which will release from the

retaining taper of the female interlock as the insert moves

down, allowing the Interchangeable Insert to drop free

from the female interlock. As previously indicated, use

an aluminum rod whose diameter is small enough to make

contact with only the Interchangeable Insert and does NOT

contact the small retaining wedges on the female interlock.

3. Repeat this procedure for each insert.

Please carefully read instructions before installing inserts.

PATENT PENDING

D-M-E Company World Headquarters 29111 Stephenson Highway, Madison Heights, MI 48071

U.S. 800-626-6653 • Canada 800-387-6600 • www.dme.net