25 catalog # bgmtip – DME Black & Gold Top Interlocks (Metric) User Manual

Page 2

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6656

CANADA 800-387-6600

www.dme.net

05-25 Catalog # BGMTIP

ME-06-0005-0012(B)

Please read carefully before installing components.

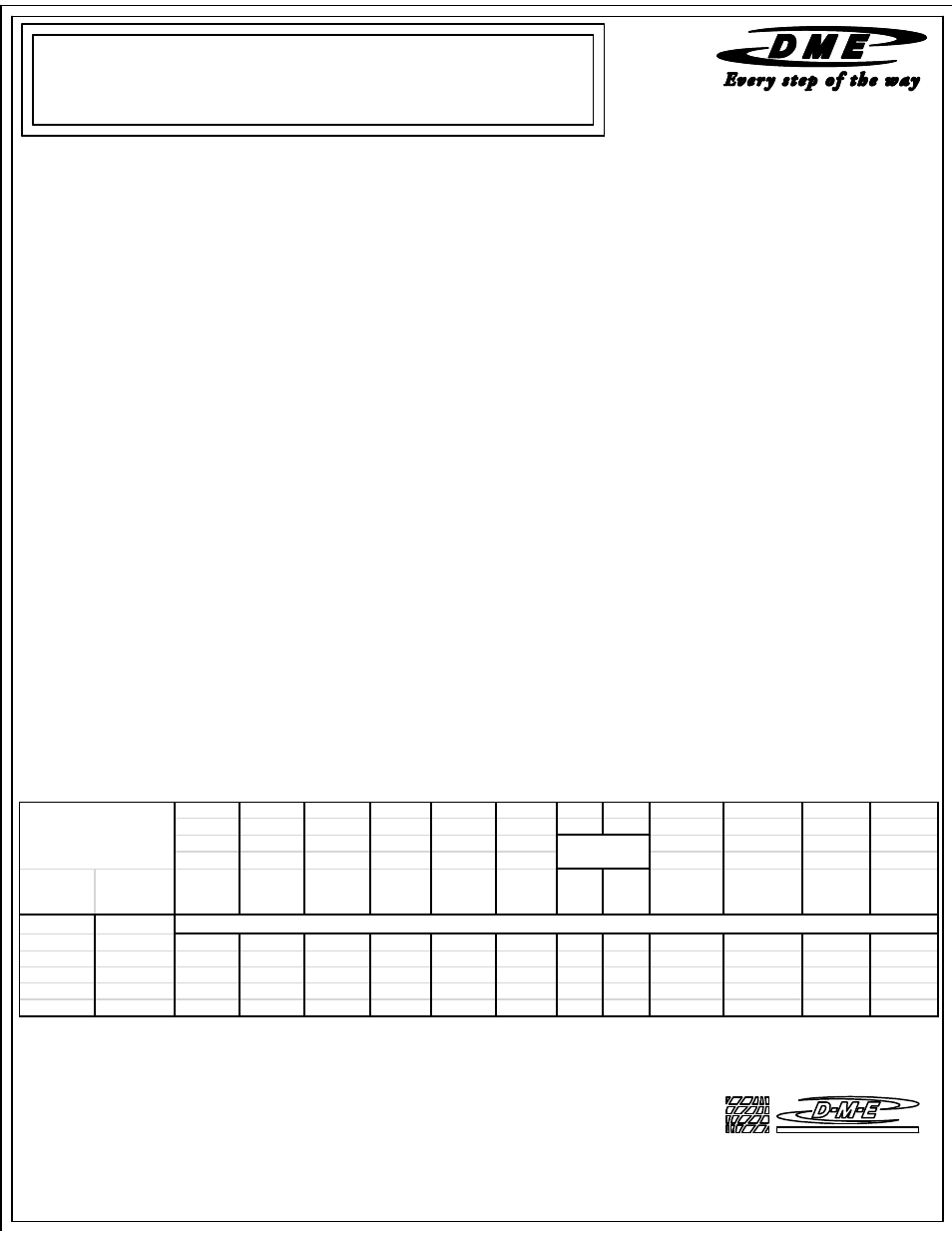

INTERLOCKS

NOTE: Dimensions are in mm.

INSTALLATION DATA

FOR BLACK &GOLD METRIC TOP INTERCHANGEABLE

WP

BM

BF

C

RF / RM

R

D

E

TM

TF

LM

LF

MALE

FEMALE

MALE

FEMALE

MALE

MALE

RADIUS

RADIUS

SHCS

SHCS

THREAD

THREAD

WIDE

WIDTH

WIDTH

DEPTH

SIZE

SIZE

LENGTH

LENGTH

+0.02

+0.01

+0.02

+0.01

+0.02

+0.01

+0.02

+0.01

+/-0.1

+/-0.1

+/-0.2

+/-0.2

M IN M IN

BGT02020F

BGT02020M

BGT03526F

BGT03526M

35.00

15.00

25.00

26.00

8.00

0.2

13.0

23.0

M5 x 20 LG

M5 x 30 LG

12.0

13.0

BGT04530F

BGT04530M

45.00

15.00

25.00

30.00

8.00

0.3

15.0

30.0

M6 x 18 LG

M6 x 30 LG

11.0

13.0

BGT05536F

BGT05536M

55.00

20.00

30.00

36.00

8.00

0.7

18.0

37.5

M8 x 25 LG

M8 x 35 LG

15.0

15.0

BGT07536F

BGT07536M

75.00

20.00

35.00

36.00

8.00

0.7

18.0

52.0

M10 x 25 LG M10 x 40 LG

17.0

17.0

BGT10045F

BGT10045M

100.00

20.00

60.00

45.00

8.00

1.0

22.5

70.0

M10 x 25 LG M10 x 65 LG

17.0

17.0

CATALOG #

SCREWS

LOCATIONS

SEE POCKETS DIMENSIONS SHOWN ON DRAWING FOR BGT02020F/BGT02020M .

Installation Instructions:

1. Four D-M-E Top Interlocks must be used in each mold application. When in operation, the

interlocks contact the edges of the machined pocket to maintain parting line alignment. The

cap screws are only utilized to retain the interlocks to the mold base.

2. To maintain alignment, it is recommended that the mold base assembly be clamped together

and machined in assembly to insure proper parting line alignment.

3. Machine the interlock pockets accurately in assembly. Locate each interlock pocket on the

centerline of the mold. The location is critical to avoid misalignment problems which could

result from uneven thermal expansion of the separate mold halves.

4. Mount the female interlock on the half of which will have the highest operating temperature.

Normally, this will be the “A” side of the mold. This procedure is critical to insure that the

male interlock does not grow larger than the female interlock if uneven mold temperatures

are present. Place the female interlocks so the relief slot are at the bottom of the pocket for

easy interlock removal. Place the male interlock with the release side facing the pocket

bottom.

5. Place both male and female interlocks into the pockets while the mold is clamped together

then thread in and tighten screws.

6. Torque the mounting SHC S to:

x 7.8 N x m [ 5.7 FT x LBS] for M4-0.7 SHCS

x 16 N x m [ 11.7 FT x LBS] for M5-0.8 SHCS

x 27 N x m [ 19.8 FT x LBS] for M6-1 SHCS

x 65 N x m [ 47.7 FT x LBS] for M8-1.25 SHCS

x 130 N x m [ 95.5 FT x LBS] for M10-1.5 SHCS

7. After installation, open and close the mold on the bench to insure proper alignment.

8. For “shuttle” molds repeat steps 2 to 7 for each interchangeable ‘B” side.