Me-x741-ps-253 - 2, D-m-e company – DME 375 Series Front Load Heater User Manual

Page 2

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6653

CANADA 800-387-6600

www.dme.net

D-M-E COMPANY

installing and/or removing heater

Please read carefully before

INSTALLATION DATA

375 SERIES FRONT LOAD HEATER

SCH9997 ME-X741-PS-253-E

small gate diameters. High injection rates may require larger gates due to shear heat build up (e.g. high weight thin wall applications). See material manufactures

For selection of tips and gate diameters it is important to take into consideration the materials flow characteristic, shear rate of resin, molding conditions, fill time

requirements, gate vestiage, wall thickness and configuration of part to be molded. Situations requiring high injections velocities must be considered when selecting

literature for further information regarding material to be molded.

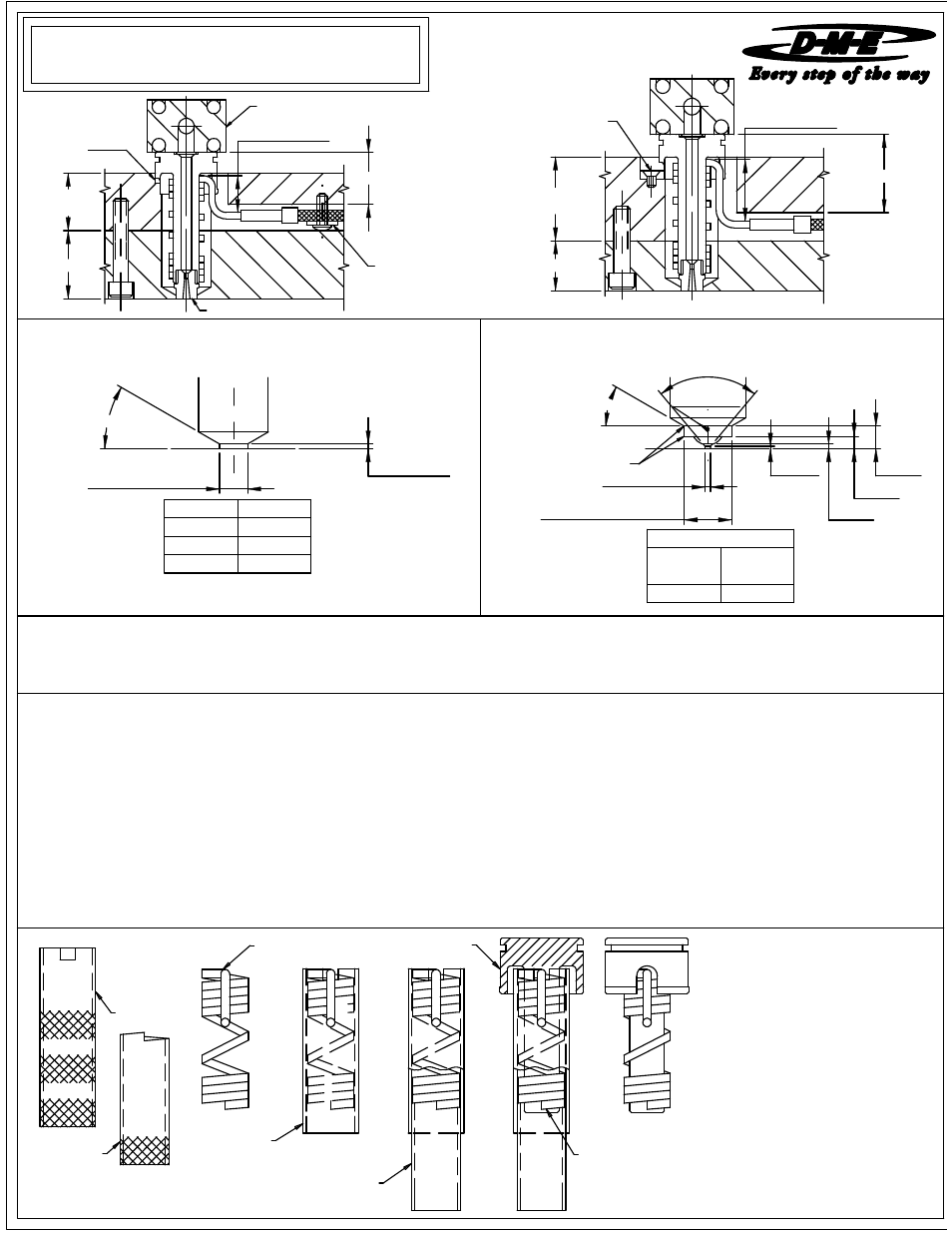

heater can be installed on the nozzle body as follows:

a. Place heater within Tube "A" so that the bending exit lead

1. Front Load Coil Heaters are designed to be used with 375 Series

Nozzles.

2. The nozzle head must be held in such a manner to keep it from

rotating upon installation of the Front Load Heater. This may

be done by making a key for the head to match the flat on the

nozzle's head or by circle interpolation.

3. Nozzle plate must be designed so that the heads of the socket

head cap screws are exposed when the mold is split on the on

the parting line.

4. After the nozzle has been located and positioned in the nozzle

plate with manifold secured in place and "A" plate removed, the

lies within the slot of the tube.

SPRUE AND RING GATE

MACHINING DIMENSIONS

chamfer.

5. The power and thermocouple leads may be spliced in the wiring

channel for ease of heater replacement. Leads may be spliced

using Thomas & Betts nylon insulated disconnects.

Male Cat. No.: 18RA-251T

Female Cat. No.: 18RA-2577

6. Secure wires in wire channel with D-M-E Wire Covers before

b. Insert Tube "B" with angle cut within Tube "A" so that the

angle of the tube mates with the last coil of the heater.

c. Rotate Tube "A" counterclockwise while at the same time rotate

Tube "B" clockwise. This action will spring open the coils

enough to slide the heater onto the shaft of the nozzle body.

d. Slide the heater onto the nozzle body shaft aligning the heater

exit lead within the relief slot in the nozzle's head.

e. Position heater so that the end of the last coil is above the

assembling "A" plate to mold.

TUBE "A"

TUBE "B"

NOZZLE BODY

TUBE "A"

TUBE "B"

LAST COIL TO

BE POSITIONED

ABOVE CHAMFER

FRONT LOAD

HEATER

FRONT LOAD COIL HEATER WRENCH

CAT. NO.: WRE0013

0.875 "B" DIM

1.125

"A" PLT

1.375

NOZZLE PLT

CIRCLE

INTERPOLATION

TUBULAR HEATED

MANIFOLD

DME WIRE

COVER

SPRUE GATE TIP SHOWN

1.875

NOZZLE PLT

"A" PLT

1.375 "B" DIM

1.625

OPTIONAL KEY

MOLDER TO

SUPPLY

30.0°

80.0°

LAND

MAX.

POINT GATE

MACHINING DIMENSIONS

.010-.015 RAD.

UNFILLED

RESIN

AT TANGENT

"O" DIA.

FILLED

.060 MIN.

RESIN

.028 MIN.

30.0°

1.000

1.0005

09-08

RECOMMENDATIONS AND GUIDELINES

.7505

.750

.5005

.500

"S" DIA.

"T" DIA.

WIRING INFORMATION

Square Coil Heaters are supplied with 2"

prestripped 36" long leads.

Heaters are 240 VAC

2 power leads are Multi Color.

1 ground lead is GREEN.

Thermocouple is "J" Type.

Thermocouple is supplied with 36" leads.

1 T/C lead is WHITE and negative (-)

constantan (non-magnetic).

1 T/C lead is BLACK and positive (+)

iron (magnetic).

LAND

+

0.020

R0.187

+

DIA

0.100

0.0005

0.080

0.0000

0.0000 DIA.

0.0005

0.005

"S"

0.5000

0.180

"O" DIA.