Installation data 375 series ring gate nozzle, D-m-e company, Important safety information – DME 375 Series Ring Gate Nozzle User Manual

Page 2: Rg3/is, Refer to : mini print # 1800, Danger warning

5 ft-lbs.

ASSEMBLY PROCEDURE

1. Nozzle body must be cleaned of any material in the seal off area and threaded

areas before reassembling.

2. Careful attention should be taken to the needle as damage could occur if needle

is dropped or strikes a rigid material. Treat needle like a glass or ceramic material.

3. Install the heater using a Square Coil Heater wrench (Wrench included with

replacement heater). After the heater is installed, it should cover the entire length

of the nozzle body - stretch the heater by hand if necessary.

4. Apply an anti-seize compound on the tip threads.

5. Firmly screw the tip sub-assembly into the shank of the nozzle body. Tighten an

untighten two or three times making sure there is a good contact between the tip

For protection of the tip sub-assembly, a six point deep well socket is recommended.

and the shank. Torque the sub-assembly into the nozzle body using 30

DANGER

WARNING

out residual moisture before applying full power. Failure to do so may cause

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn. This product

has heated surfaces. Use caution when operating and servicing the system

to avoid severe burns. Proper protective equipment should be worn.

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it can cause fire, severe

injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

damage to this product.

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

CANADA 800-387-6600

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6656

www.dme.net

OPERATING PROCEDURE

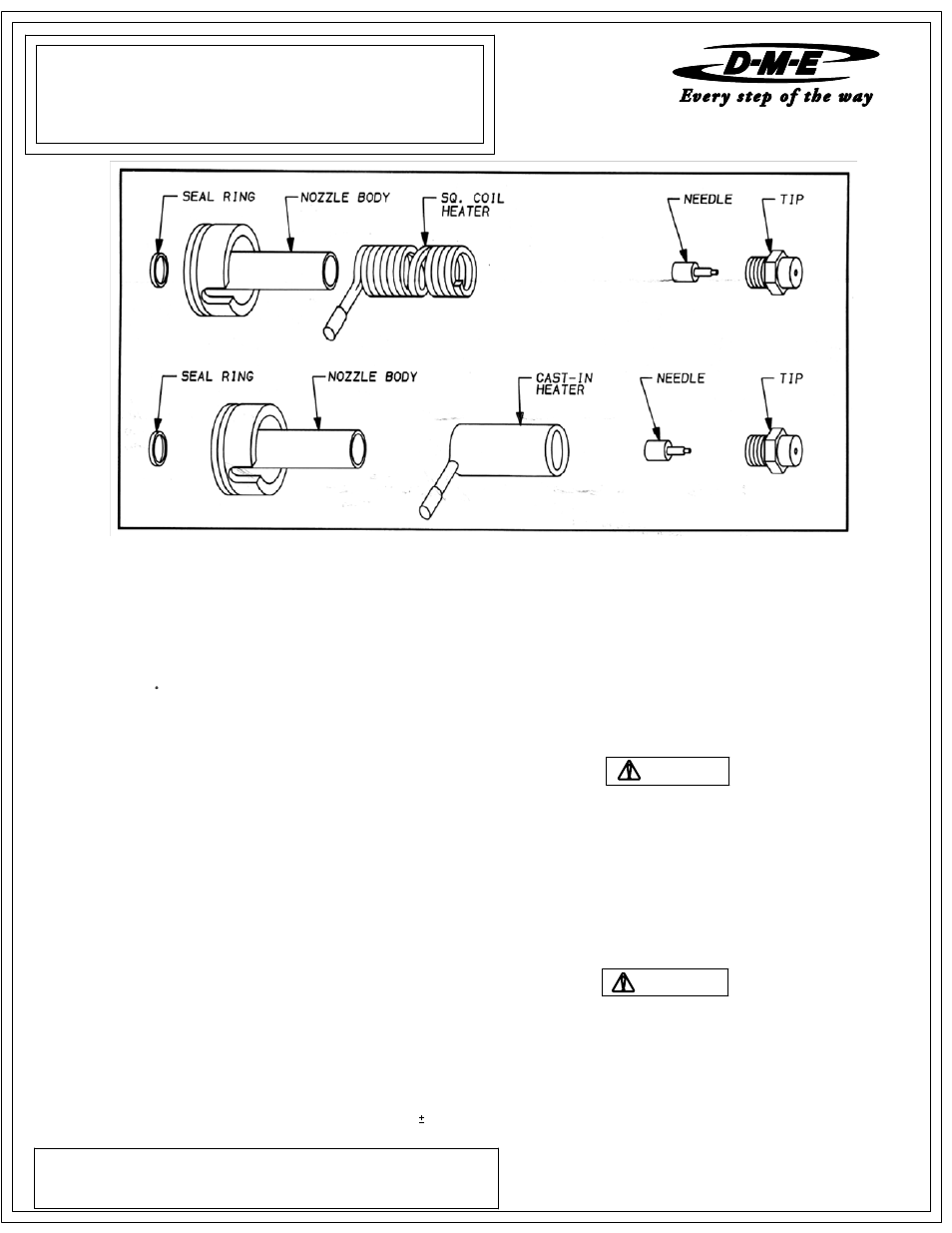

The nozzles are supplied with a Square (flat) Coil Heater or Cast-In Heater

equipped with type J thermocouple.

It is recommended to use a D-M-E closed loop Temperature Controller for

optimumTemperature Control.

When starting the nozzle, set the temperature to 10% voltage if using in open loop

manual type or to 200 F if using closed loop automatic type. In either case this

procedure will allow the heater to dissipate any moisture.

Make sure you maintain this start-up setting for 15 minutes.

Controller equipped with Step Smart ® , Smart Step ®

or other heater warm-up circuitry will change automatically.

It is essential to use controllers with the proper voltage and wattage capabilities.

The voltage and wattage of each heater is clearly marked on the heater tag.

Step Smart ®, Smart Start ® and DME ® are all registered trademarks

of DME Company.

REFER TO : MINI PRINT # 1800

INSTALLATION DATA

375 SERIES RING GATE NOZZLE

RG3/IS

heat to transfer into the tip before molding.

8. Wait a minimum of 5 minutes after set point has been achieved for sufficient

manifold are removed to ensure seal-off.

7. Seal ring for nozzle body must be replaced each time nozzle body and / or

damage could occur when working on nozzle assembly.

6. Careful attention should be taken to the heater / thermocouple leads as

ME-0741-PS-550-D

capacity. The information found below applies to the 375 Series Ring Gate Nozzles.

All interchangeable nozzles are similar, and differ only in size and material flow

FOR 375 SERIES RING GATE NOZZLES

OPERATING & SERVICING INSTRUCTIONS

Heater. Follow assembly procedures for Square Coil Heater.

08-08

5. Cast-In Heater may be removed if failure occurs and replaced with a Square Coil

replacement heater).

4. Remove the heater using a Square Coil Heater wrench (Wrench is included with

3. Tip and needle must be cleaned of any material before reassembling.

the nozzle must be "keyed" to prevent wire damages.

when removing tip counter-clockwise from the nozzle. If nozzle is still in the mold,

nozzle must be at processing temperature and the heater should be turned off

2. For removal of tip from nozzle, a six point deep well socket is recommended. The

1. Place the nozzle in a vice using "V" Block, then secure it firmly at the nozzle head.

DISASSEMBLY PROCEDURE

D-M-E COMPANY