0 wiring the tla – Red Lion TLA User Manual

Page 5

5

2.0 WIRING THE TLA

After the unit has been mechanically mounted, it is ready to be wired. All

wiring connections are made to the rear screw terminals. When wiring the unit,

use the numbers on the label and those embossed on the back of the case, to

identify the position number with the proper function.

All conductors should meet voltage and current ratings for each terminal.

Also cabling should conform to appropriate standards of good installation, local

codes and regulations. It is recommended that power supplied to the unit (AC

or DC) be protected by a fuse or circuit breaker. Strip the wire, leaving

approximately 1/4" (6 mm) bare wire exposed (stranded wires should be tinned

with solder). Insert the wire under the clamping washer and tighten the screw

until the wire is clamped tightly.

Caution: Unused terminals are NOT to be used as tie points. Damage to the TLA

may result if these terminals are used.

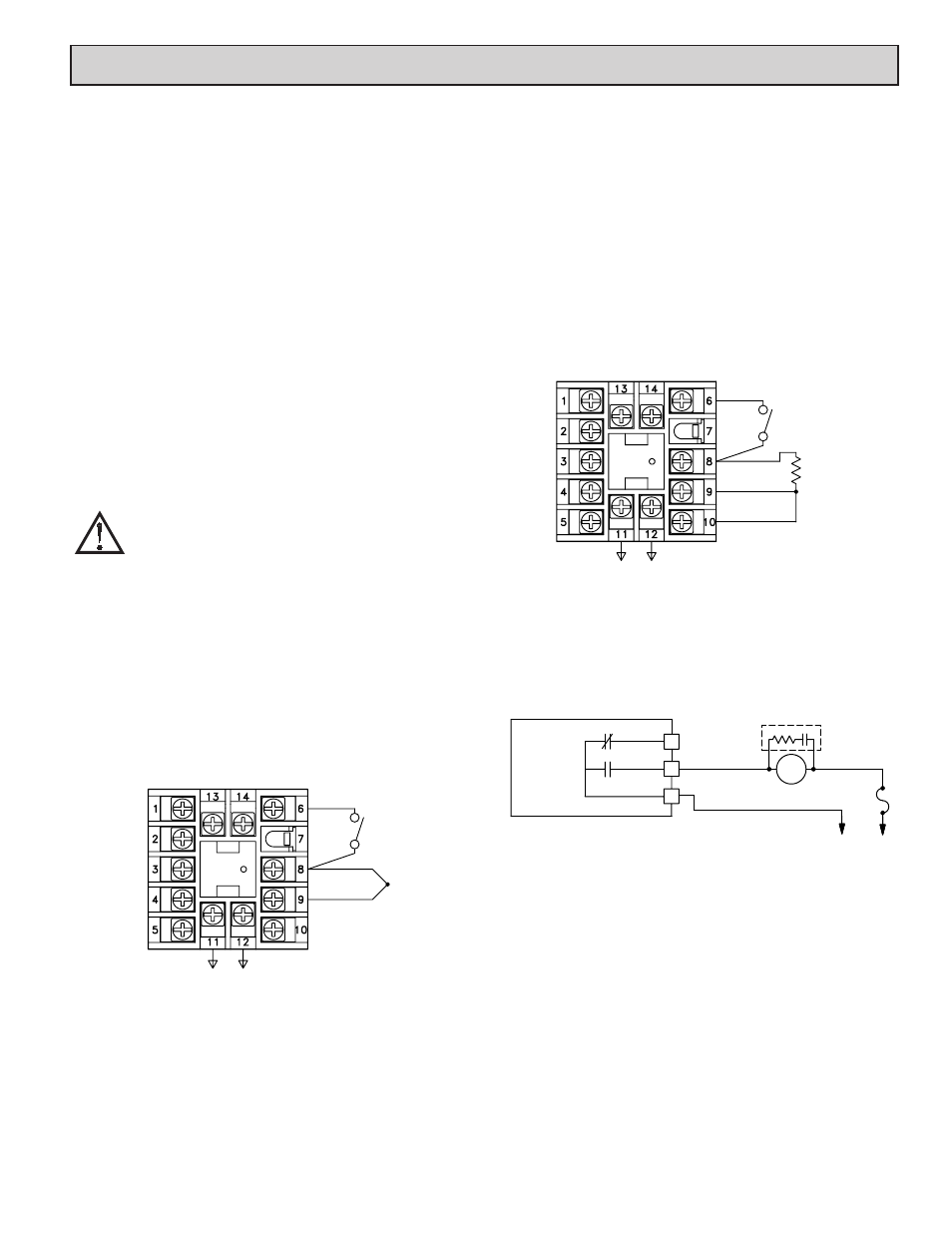

POWER WIRING

AC Power

Primary AC power is connected to terminals #11 and #12, labeled AC. To

reduce the chance of noise spikes entering the AC line and affecting the TLA,

an AC feed separate from that of the load should be used to power the TLA. Be

certain that the AC power to the TLA is relatively “clean” and within the

variation limit. Connecting power from heavily loaded circuits or circuits that

also power loads that cycle on and off (contacts, relays, motors, etc.), should be

avoided.

DC Power

DC Power (18 to 36 VDC) is connected to terminals #11 and #12 labeled

DC+ and DC- respectively.

CAUTION: Observe proper polarity when connecting DC voltages.

Damage to the unit may occur if polarity is reversed.

SIGNAL WIRING

Thermocouple

When connecting the thermocouple, be certain that the connections are clean

and tight. If the thermocouple probe cannot be connected directly to the TLA,

thermocouple wire or thermocouple extension-grade wire must be used to

extend the connection points (copper wire does not work). Always refer to the

thermocouple manufacturer’s recommendations for mounting, temperature

range, shielding, etc. For multi-probe temperature averaging applications, two

or more thermocouple probes may be connected to the TLA (always use the

same type). Paralleling a single thermocouple to more than one TLA is not

recommended. Generally, the red wire from the thermocouple is negative and

connected to the TLA’s common.

RTD

When connecting the RTD, be certain that the connections are clean and

tight. RTD sensors have a higher degree of accuracy and stability than

thermocouple sensors. Most RTD sensors available are the three wire type. The

third wire is a sense lead for canceling the effects of lead resistance of the probe.

Four wire RTD elements may be used by leaving one of the sense leads

disconnected. Two wire RTD sensors may be used in either of two ways:

A) Attach the RTD to terminals #8 and #10. Install a copper sense wire of the

same wire gauge as the RTD leads. Attach one end of the wire at the probe

and the other end to terminal #9. Complete lead wire compensation is

obtained. This is the preferred method.

B) Attach the RTD to terminals #8 and #10. Install a shorting wire between

terminals #9 and #10. A temperature offset error of 2.5°C/ohm of lead

resistance exists. The error may be compensated by programming a

temperature offset.

Note: With extended cable runs, be sure the lead resistance is less than 15 ohms/

lead.

RELAY CONNECTIONS

To prolong contact life and suppress electrical noise interference due to the

switching of inductive loads, it is good installation practice to install a snubber

across the contactor. Follow the manufacturer's instructions for installation.

Note: Snubber leakage current can cause some electromechanical devices to be

held ON.

*Terminal numbers are model dependent. See Terminal Configurations for

description.

REMOTE RESET WIRING

The use of shielded cable is recommended. Follow the EMC installation

guidelines for shield connection.

Terminal #6 is the Remote Reset. Any form of mechanical switch may be

connected to terminal #6 (REMOTE RESET) and terminal #8 (COMM.).

Sinking open collector logic with less than 0.7 V saturation and off-state leakage

current of less than 1 µA may also be used.

POWER

-

+

CONNECTION

NO

TC

COMM.

USER INPUT

AT

5 AMPS

250 VAC

CONTROLLER

N.O.

LOAD

FUSE

N.C.

AC/DC

POWER

*

*

*

Thermocouple Connection

RTD Connection

POWER

COMM.

RTD

USER INPUT

RTD

PROBE