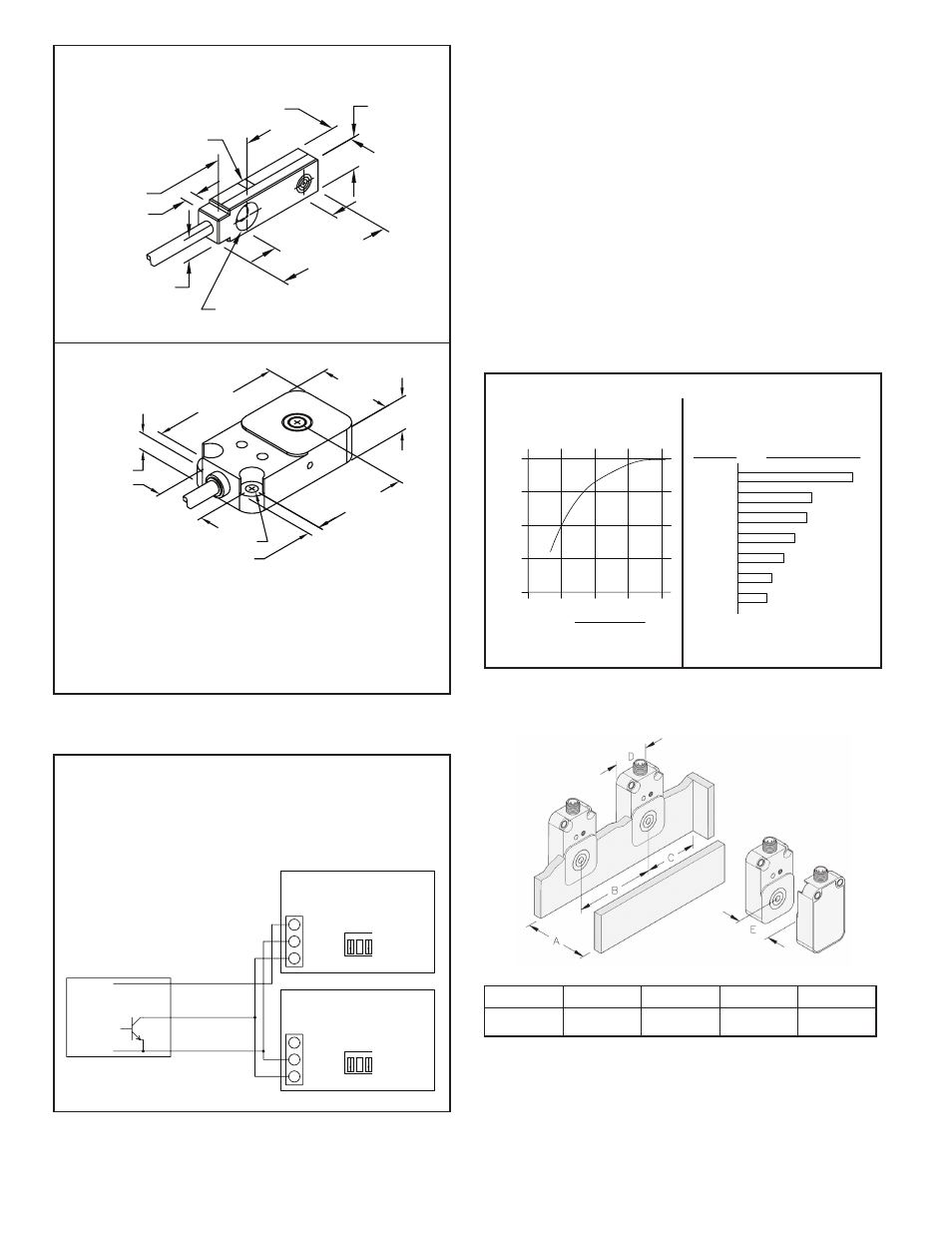

Selection & application of proximity sensors, Dimensions in inches (mm), Maximum sensing distance reduction factors – Red Lion PSAFP - FLAT PACK User Manual

Page 2: Psafp100, Psafp200 mounting, Psafp200

100%

APPROX. 65%

APPROX. 60%

APPROX. 50%

APPROX. 40%

MILD STEEL

STAINLESS

MERCURY

LEAD

BRASS

STEEL

MATERIAL

% SENSING DISTANCE

Nominal sensing range x % sensing

distance = actual sensing range

APPROX. 25%

APPROX. 30%

COPPER

ALUMINUM

0

.25

.5

.75

1

0

50

100

% OF MAX. SENSING DISTANCE

RATIO,

SENSOR DIAMETER

TARGET DIAMETER

1 2 3

SR

C

LO FR

Q

LO BIAS

SN

K

HI

HI

*

*

HI

SN

K

HI

LO BIAS

3

LO FR

Q

SR

C

1 2

APPLICATION

DEPENDENT

APPLICATION

DEPENDENT

TYPICAL COUNTER

INPUT SWITCH SET-UP

INPUT SWITCH SET-UP

TYPICAL COUNTER

NPN OPEN

COLLECTOR

PSAFP1 and PSAFP2

+VDC (BRN)

OUTPUT (BLK)

COMMON (BLU)

COUNTER #2

COUNTER #1

+12V

COMM.

CNT.

CNT.

COMM.

+12V

*

*

SELECTION & APPLICATION OF PROXIMITY

SENSORS

Selection of the proper proximity sensor depends on the size, material, and

spacing of the target being sensed and the sensing distance that can be

maintained. The maximum sensing distance is defined as the distance when the

sensor is just close enough to detect a ferrous target whose diameter is equal to

or greater than the sensor diameter. In actual application, the sensing distance

should be between 50 to 80% of the maximum sensing range to assure reliable

detection. For target sizes smaller than the sensor diameter, the maximum

sensing distance can be estimated from the curve (See Figure 3). A further

reduction factor must also be applied if the target material is non-ferrous metal

(See Figure 4). Ideally, spacing between adjacent targets should be at least one

sensor diameter so that the first target completely leaves the sensors field before

the next target appears. Individual targets can still be resolved as separate

objects if this spacing is reduced to 70 or 75% of the sensor diameter, however,

this can introduce a minimum limit on sensing distance that makes adjustment

more critical. All proximity sensors are internally shielded which allows the

sensor face to be flush mounted in metal applications without reducing sensing

distance. In applications where proximity sensors must be placed next to each

other, a distance of at least 1 sensor diameter should separate sensors to

eliminate any frequency interference (See Mounting below).

PSAFP100 and PSAFP200 outputs are NPN open collector outputs. A

PSAFP100 and PSAFP200 may be used as an input to more than 1

indicator or control only if the respective power supplies of each unit

are “unregulated” and can load share. It is recommended to use only

one power supply for sensor power. An indicator or control with a

regulated power supply may not be paralleled.

MAXIMUM SENSING DISTANCE REDUCTION FACTORS

Reduction in the maximum sensing

distance due to decrease in diameter

of ferrous targets.

Typical reduction factors for various non-

ferrous targets with diameters equal to or

greater than sensor diameter.

Counter #1 and #2 both contain

unregulated +12 VDC Power

Supplies.

Figure 3

Figure 4

DIMENSIONS In inches (mm)

LED

Ш 0.126 (Ш 3.2) THRU

Ш 0.252 (Ш 6.4) x90°

0.315 (8.0)

0.217 (5.5)

0.315 (8.0)

0.630 (16.0)

1.102 (28.0)

0.118 (3.0)

0.236 (6.0)

PSAFP100

Notes:

1. PSAFP100 Housing: Plastic, PA12-GF30

Cable: 2 meter standard length

2. PSAFP200 Housing: Plastic, PBT-GF30-VO

Cable: 2 meter standard length

PSAFP200 MOUNTING

Ш 0.177 (Ш 4.5) 2x

0.787 (20.0)

2.047 (52.0)

1.181 (30.0)

0.551(14.0)

1.260 (32.0)

0.197 (5.0)

0.315 (8.0)

PSAFP200

A

B

C

D

E

30.00 mm

45.00 mm

30.00 mm

30.00 mm

60.00 mm