Red Lion MP-STANDARD MAGNETIC PICKUPS User Manual

Magnetic pickups & in-line preamplifier, Simple, reliable & economical pulse generators for, Description of operation

1

OUTPUT VOLTAG

E

+

-

(A)

SMALL

GEAR

GEAR

OPTIMUM

(B)

GEAR

LARGE

(C)

KEYWAY

SHAFT

(D)

HEAD

BOLT

(E)

CAM

(F)

MAG.

PICKUP

DIA.=d

POLE

d

3d

d

EDGE

LEADING

TRAILING

EDGE

TRAILING

EDGE

LEADING

EDGE

100

75

50

25

0

0

5

10

15

20

25

AIR GAP (INCHES x .001)

REL. OUTPUT

%

SPEED SWITCHES

DIGITAL TACHOMETERS

FREQUENCY TO D.C. CONVERTERS

FEATURES INCLUDE

SELF-GENERATING, NO EXT. POWER NEEDED

WIDE OPERATING TEMPERATURE RANGE

EPOXY ENCAPSULATED, MECHANICALLY RUGGED

IMPERVIOUS TO DIRT, OIL & WATER

NO MAINTENANCE REQUIRED

LOW COST

M12 CONNECTOR (MODEL SPECIFIC)

DESCRIPTION OF OPERATION

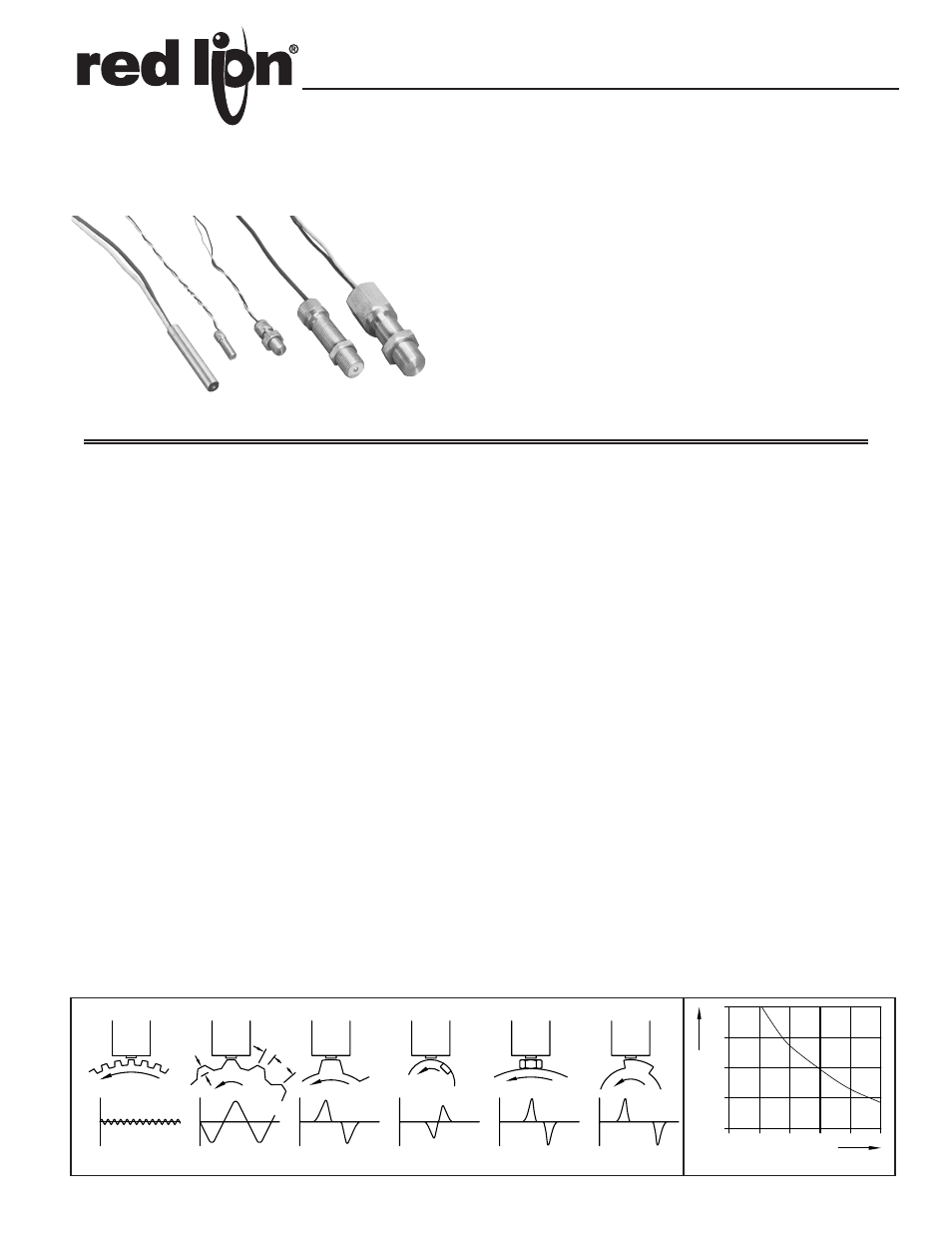

A Magnetic Pickup consists of a permanent magnet, a pole-piece, and a

sensing coil all encapsulated in a cylindrical case. An object (target) of iron,

steel, or other magnetic material, passing closely by its pole-piece causes

distortion of the magnetic flux field passing through the sensing coil and pole-

piece, which in turn generates a signal voltage. The magnitude of the signal

voltage depends on the relative size of the magnetic target, its speed of

approach, and how close it approaches. The polarity of the signal depends on

whether the target is moving toward or away from the pole-piece.

Magnetic Pickups are most frequently used to sense passing teeth on a gear,

sprocket, or timing belt wheel, to bolt-heads, key-ways, or other moving

machine mounted targets. Typical targets and resulting signal wave forms are

shown below in Fig. 1.

SELECTING A MAGNETIC PICKUP

Selecting a magnetic pickup is a matter of matching a pickup to a gear (or

other target), to provide enough input signal to a tachometer, speed-switch, or

other device for operation at the required minimum speed. The open-circuit

output from a magnetic pickup is directly proportional to speed, and once the

minimum operating speed conditions have been met, excess signal will always

be available at higher speeds.

The “1-Volt Threshold Speed” column in the Application and Ordering Table

(next pg.) provides a convenient guide for estimating minimum operating

speeds. This value is the linear surface-speed of a reference gear required to

generate a 1-Volt peak, open-circuit output at an air-gap of 0.005". The

reference gear listed for each pickup is near the optimum size for that pickup,

as defined by the criteria in Fig. 1B. The RPM listed is for a reference gear with

60 teeth running at that surface-speed. Gears with larger teeth provide about the

same or somewhat more output at the same surface-speed, while gears with

smaller teeth or fewer number of teeth yield lower outputs. Figures 1C - 1F need

a very high surface speed to generate a 1-Volt peak. The “Minimum Gear Size”

column lists the Diametral Pitch size at which the output drops to 40-60% of the

output when the reference gear is used. Gears with very small teeth in relation

to the pole-piece diameter, deliver greatly reduced outputs, as shown in Fig. 1A.

Threshold outputs when using targets other than gear teeth can be estimated by

their relative size with respect to the reference gear teeth. For more information

on gears, definitions and relationships, see the Sensing Gears Bulletin.

The 1-Volt Threshold Speeds are based on a 0.005" air-gap. In applications

where this air-gap cannot be maintained or where the air-gap can vary due to

eccentricity of the sensing gear, a correction factor can be applied from the

curve in Fig 2. The effect of electrical loading is usually minimal at low speeds

and low output frequencies, however, output voltage drop due to loading at high

frequency or with low impedance inputs can be estimated based on the Output

Impedance data.

Note: Magnetic Pickups are used primarily for tachometer and other speed

related functions. They are not normally used for counting since loss of

counts will occur at low speeds. Therefore, counters are not designed to

accept outputs directly from conventional magnetic pickups. In special

applications where counting occurs only at running speed or where low-

speed count loss is acceptable, a Model ASTC can be used, or a different type

of sensor can be used as a substitute.

TYPICAL APPLICATION EXAMPLE

A Digital Tachometer, with an input sensitivity of 0.25 V is to be used with a

Magnetic Pickup and gear to indicate speed down to 75 RPM. What are the

alternative choices?

Since the input voltage required by the tachometer is only 0.25 V, the surface

speeds and reference gear RPM’s required would only be 2 of the 1-Volt

Threshold Speeds listed. The MP-25TA with a 60-tooth, 24 D.P. reference gear

would obviously fall short since this combination will not develop 0.25 V until

the reference gear speed reaches 250 RPM.

The MP-37CA with the 60-tooth, 20 D.P. reference gear would both prove

suitable since they would deliver the required 0.25 V at 50 and 45 RPM

respectively. They would also provide some additional margin for air-gap

variation. The curve of Fig. 2 shows a typical output drop of about 25% when

the air-gap is increased from 0.005" to 0.0075". Since the minimum operating

speed in this application is 75 RPM, the additional sensitivity can be traded for

a wider air-gap allowance.

The MP-62TA and MP-75TX with their respective reference gears would

allow operation at even lower speeds. With both of these pickups it would be

possible to drop to a smaller gear pitch for this application.

MAGNETIC PICKUPS & IN-LINE PREAMPLIFIER

SIMPLE, RELIABLE & ECONOMICAL PULSE GENERATORS FOR:

FIG. 1 OUTPUT WAVEFORMS WITH VARIOUS TARGET SHAPES & SIZES

FIG. 2 TYPICAL OUTPUT/AIR-GAP

Bulletin No. MP-L

Drawing No. LP0020

Released 02/10

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net