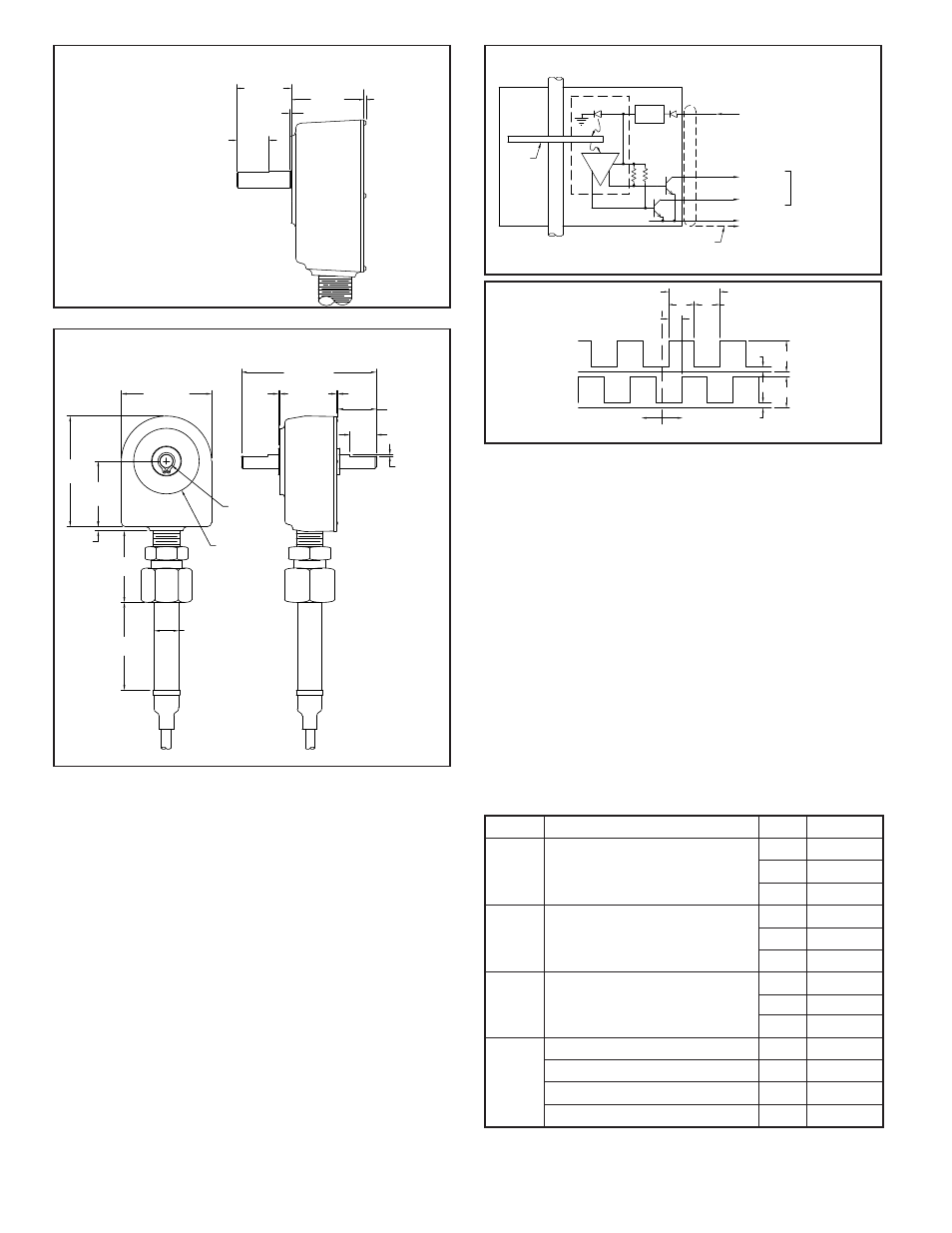

Specifications, Zfh dimensions in inches (mm), Zgh dimensions in inches (mm) – Red Lion ZCH - STANDARD DUTY, QUAD User Manual

Page 2: Ordering information, Length sensor mounting consideration, Equivalent circuit & connections, Electrical specifications, Mechanical specifications

SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

1. SUPPLY VOLTAGE: +8 to +28 VDC (including power supply ripple) @ 50

mA max. (30 mA typ.); Reverse polarity protected.

2. OUTPUTS: NPN Open Collector Transistor, V

OH

= 30 VDC max., V

OL

= 1

V max @ 40 mA. Output current is limited to 40 mA. Incremental - Two

square waves in quadrature with Channel A leading B for clockwise rotation.

3. OUTPUT FREQUENCY: Up to 50 KHz

4. OUTPUT DUTY CYCLE: Channel A & B: 50/50 nominal. (See Figure 1,

Note 3)

5. QUADRATURE OUTPUT PHASE: 90° ±15° (See Figure 1, Note 3)

6. CABLE CONNECTIONS: RED = +VDC; BLACK = Common;

WHITE = Channel A Output; GREEN = Channel B Output.

MECHANICAL SPECIFICATIONS

1. MAXIMUM MECHANICAL SPEED: 6000 RPM

2. RADIAL SHAFT LOAD: 15 lbs. max. (66.7N)

3. AXIAL SHAFT LOAD: 15 lbs. max. (66.7N)

4. STARTING TORQUE: 3 oz.-in. (21.2N-mm)

5. MOMENT OF INERTIA:

Single Shaft = 1.03 x 10

-4

oz. - in. - sec.

2

(7.30 x 10

-4

N - mm - sec

2

)

Dual Shaft = 1.30 x 10

-4

oz. - in. - sec.

2

(9.21 x 10

-4

N - mm - sec

2

)

6. OPERATING TEMPERATURE: 0°C to +70°C

7. WEIGHT (LESS CABLE):

ZCH: 14.3 oz (406 g)

ZFH: 22.0 oz (623 g)

ZGH: 22.7 oz (643 g)

1.65

0.08 (2.03)

0.75

0.04

1.20

MAX.

(30.5)

(41.9)

(1.0)

(19.0)

ZFH DIMENSIONS In inches (mm)

.75 (19) DIA.

2.75

(69.8)

2.06

(52.3)

2.00

(50.8)

.13 (3.3)

3.38

(85.8)

2.75 (69.9)

4.00 (101.6)

1.65 (41.9)

0.375 (9.52)

DIA. SHAFT

2.00 (50.8) DIA.

.04

(1.0)

.08

(2.03)

MAX.

USABLE SHAFT

LENGTH

1.08 (27.4)

REF., TYP. 2

.75

(19.0)

TYP. 2

.022 (.56)

TYP. 2

ZGH DIMENSIONS In inches (mm)

This is the side view of the Model

ZFH. All other dimensions (including

the handle tube) are the same as

the Model ZGH. See below.

2

LED

REGU-

LATOR

RED

WHT

BLK

COMMON

8-28VDC @ 30mA

V = 30VDC MAX.

V = 1V MAX. @ 40mA

OL

OH

SHAFT

METAL

ETCHED

OPTICAL

DISC

BARE STRANDED SHIELD WIRE

CONNECTED TO INSTRUMENT

COMMON FOR INCREASED

NOISE IMMUNITY

SENSOR

ARRAY

(TYP.) 50mA MAX.

GRN

CHANNEL A

CHANNEL B

EQUIVALENT CIRCUIT & CONNECTIONS

MODEL NO.

DESCRIPTION

PPR

PART NUMBER

100

100

100

ZGH0100C

ZFH0100C

ZCH0100C

--

200

200

200

ZGH0200C

ZFH0200C

ZCH0200C

500

500

500

ZGH0500C

ZFH0500C

ZCH0500C

ZGH

ZFH

ZCH

Length Sensor

Double Shaft

(Replaces LSQD)

Length Sensor

Single Shaft

(Replaces LSQS)

Rotary Pulse Generator

(Replaces RPGQ)

RPGFC002

--

--

--

Flexible Coupling (1" Length) 0.375" - 6 mm

Flexible Coupling (1" Length) 0.375" - 0.500"

Flexible Coupling (1" Length) 0.375" - 0.375"

RPGFC

RPGFC006

RPGFC004

RPGFC003

Flexible Coupling (1" Length) 0.250" - 0.375"

Note: For 25 foot cable, replace the last character of the part number (“C”) with “D”.

For 50 foot cable, replace the last character of the part number (“C”) with “E”.

ORDERING INFORMATION

NOTES:

1. Channel A leads Channel B for clockwise shaft rotation when viewed from

housing front. Conversely, Channel B leads Channel A for Counterclockwise

shaft rotation.

2. The number of lines on the optical disc determines the Pulses Per Revolution

(PPR).

3. Duty Cycle is the relationship of output “High” time, “a”, to output “Low”

time, “b”, and is expressed as a High/Low percentage ratio, ie....% High time

= a/(a+b) x 100; % Low time = b/(a+b) x 100.

4. Quadrature Phase “c” is specified as the lead or lag between Channel A & B

in electrical degrees. Nominally 90° (1/4 cycle).

LENGTH SENSOR MOUNTING CONSIDERATION

1. Length Sensors should be mounted so measuring wheel(s) contact ribbon,

strip or web as it passes over a roller. As an alternative, wheel(s) can be driven

by roller surface next to material being measured.

2. Note: The weight at the Length Sensor unit provides sufficient traction for

accurate operation when mounted, with arm angle from horizonal not

exceeding ±30

o

.

3. Tension on signal cable can cause wheel(s) to lift. Make sure cable is clamped

to machine frame near the unit and allow slack.

V

OL

V

OH

COMMON

OH

V

OL

V

COMMON

C.W.

C.C.W.

SHAFT ROTATION

(NOTE 1)

CHAN. B

CHAN. A

(NOTE 4)

"c"

"a"

"b"

(NOTE 3)

1 CYCLE (360°)

(NOTE 2)