Installation, Output wiring, Setpoint adjustment – Red Lion CTS User Manual

Page 2: Trouble shooting, Ordering information

INSTALLATION

Run wire to be monitored through opening in the sensor. The CTS Series

transducers work in the same environment as motors, contactors, heaters, pull-

boxes, and other electrical enclosures. They can be mounted in any position or

hung directly on wires with a wire tie. Just leave at least one inch (25.4 mm)

distance between sensor and other magnetic devices.

Split-Core Versions

Press the tab in the direction as shown to open the sensor. After placing the

wire in the opening, press the hinged portion firmly downward until a definite

click is heard and the tab pops out fully.

KEEP SPLIT-CORE SENSORS CLEAN.

Silicone grease is factory applied on the mating surfaces to prevent rust and

improve performance. Be careful not to allow grit or dirt onto the grease in the

contact area. Operation can be impaired if the mating surfaces do not have good

contact. Check visually before closing.

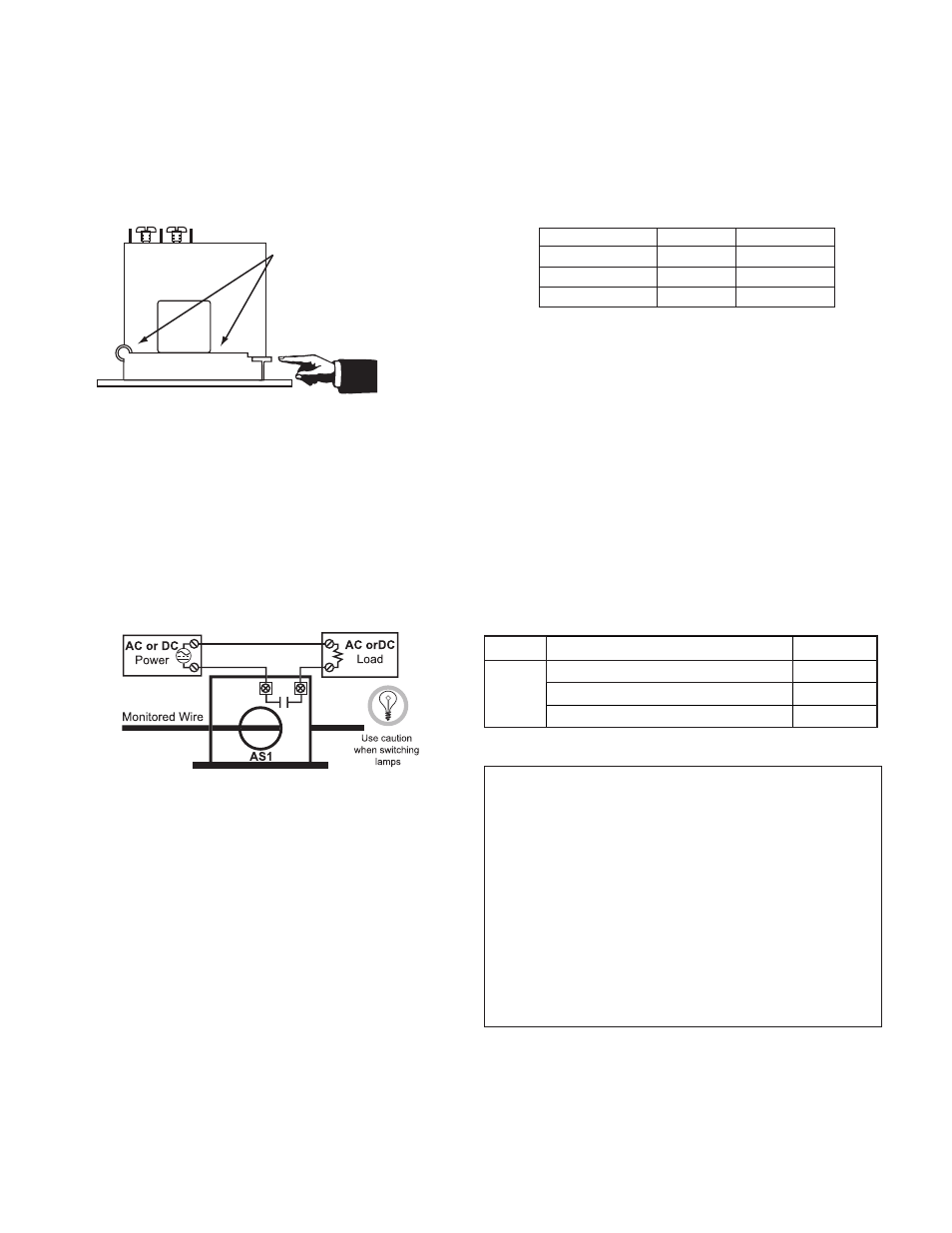

OUTPUT WIRING

Connect control or monitoring wires to the sensor. Use up to 14 AWG copper

wire and tighten terminals to 5 inch-pounds torque. Be sure the output load does

not exceed the switch rating.

CAUTION: Incandescent lamps can have “Cold Filament Inrush” current of up

to 10 times their rated amperage. Use caution when switching lamps.

SETPOINT ADJUSTMENT

CTS Series SETPOINT is adjusted with a 4-turn potentiometer (CTSS) or a

15-turn potentiometer (CTSF). The pot is shipped factory set to the lowest

setpoint, fully clockwise (CW). Turning the pot counter-clockwise (CCW) will

increase the setpoint. The pot has a slip-clutch to prevent damage at either end

of its rotation. To determine where the adjustment is, turn the pot all the way

CW. This will return it to the minimum setpoint.

Adjustment Notes:

1. Output contacts are solid-state. Check output status by applying voltage to the

contacts and reading the voltage drop across the contacts. An Ohmmeter set

on “Continuity” will give misleading results.

2. It is recommended that the setpoint be adjusted to allow for voltage variations

of 10-15%.

Typical Adjustment

1. Turn the pot to minimum setpoint (4 or 15 turns CW).

2. Have normal operating current running through the sensor. The output

should be tripped since the pot is at its minimum setpoint. For units with

LED, it should be flashing fast (2 to 3 times per second).

3. Turn the pot CCW until the unit un-trips. This is indicated by the slow

flashing of the LED (once every 2 to 3 seconds), or by the changing of

the output switch status.

4. Now turn the pot CW slowly until the unit trips again.

It is now set at the current level being monitored.

A. To Set UNDERLOAD - Turn the pot about 1/8 turn further CW.

B. To Set OVERLOAD - Turn the pot about 1/8 turn further CCW.

TROUBLE SHOOTING

1. Sensor Is Always Tripped

A. The setpoint may be too low. Turn pot CCW to increase setpoint.

B. Switch has been overloaded and contacts are burned out. Check the output

load, remembering to include inrush on inductive loads (coils, motors,

ballasts).

2. Sensor Will Not Trip

A. The setpoint may be too high. Turn pot CW to decrease setpoint.

B. Split Core models: The core contact area may be dirty. Open the sensor and

clean the contact area.

C. Monitored current is below minimum required. Loop the monitored wire

several times through the aperture until the “sensed” current rises above

minimum. Sensed Amps = (Actual Amps) x (Number of Loops). Count

loops on the inside of the aperture.

D. Switch has been overloaded and contacts are burned out. Check the output

load, remembering to include inrush on inductive loads (coils, motors,

ballasts).

Important!

Keep Contact

Area CLEAN!

To Open

Press Tab

Toward Hinge.

DESCRIPTION

PART NUMBERS

CTS

.75 A Fixed-Core Current Switch, Go-No Go

1-150 A Fixed-Core Current Switch, Adjustable

CTSG0000

CTSF0000

CTSS0000

ORDERING INFORMATION

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and

workmanship for a period limited to two years from the date of shipment, provided the

products have been stored, handled, installed, and used under proper conditions. The

Company’s liability under this limited warranty shall extend only to the repair or

replacement of a defective product, at The Company’s option. The Company disclaims

all liability for any affirmation, promise or representation with respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify

RLC against damages, claims, and expenses arising out of subsequent sales of RLC

products or products containing components manufactured by RLC and based upon

personal injuries, deaths, property damage, lost profits, and other matters which Buyer,

its employees, or sub-contractors are or may be to any extent liable, including without

limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and

liability imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L.

93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products

except those expressly contained herein. The Customer acknowledges the disclaimers

and limitations contained herein and relies on no other warranties or affirmations.

MODEL NO.

MONITORED AMPS

OUTPUT

SMART-LED

None or OPEN OFF Below Trip Level OPEN SLOW (2 sec) Above Trip Level CLOSED FAST (0.5 sec) 1.75-150 A Split-Core Current Switch, Adjustable Red Lion Controls Red Lion Controls AP Unit 101, XinAn Plaza Building 13, No.99 Tianzhou Road ShangHai, P.R. China 200223 Tel +86 21 6113-3688 Fax +86 21 6113-3683 Red Lion Controls BV Printerweg 10 NL - 3821 AD Amersfoort Tel +31 (0) 334 723 225 Fax +31 (0) 334 893 793

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839