Wire connections, Torque requirements – Outback Power Systems VFX Series International Installation Manual User Manual

Page 14

12

WIRE CONNECTIONS

NOTE:

A system’s individual voltage requirements (230 or 3-phase) as well as how each FX is to

function all determine how the FXs are wired. Each FX must be wired to the logical leg or phase of the

system. Each FX must be programmed or “stacked” according to this phase. Please see the International

FX and VFX Series Inverter/Charger Programming Manual before connecting any wires to or from the FX.

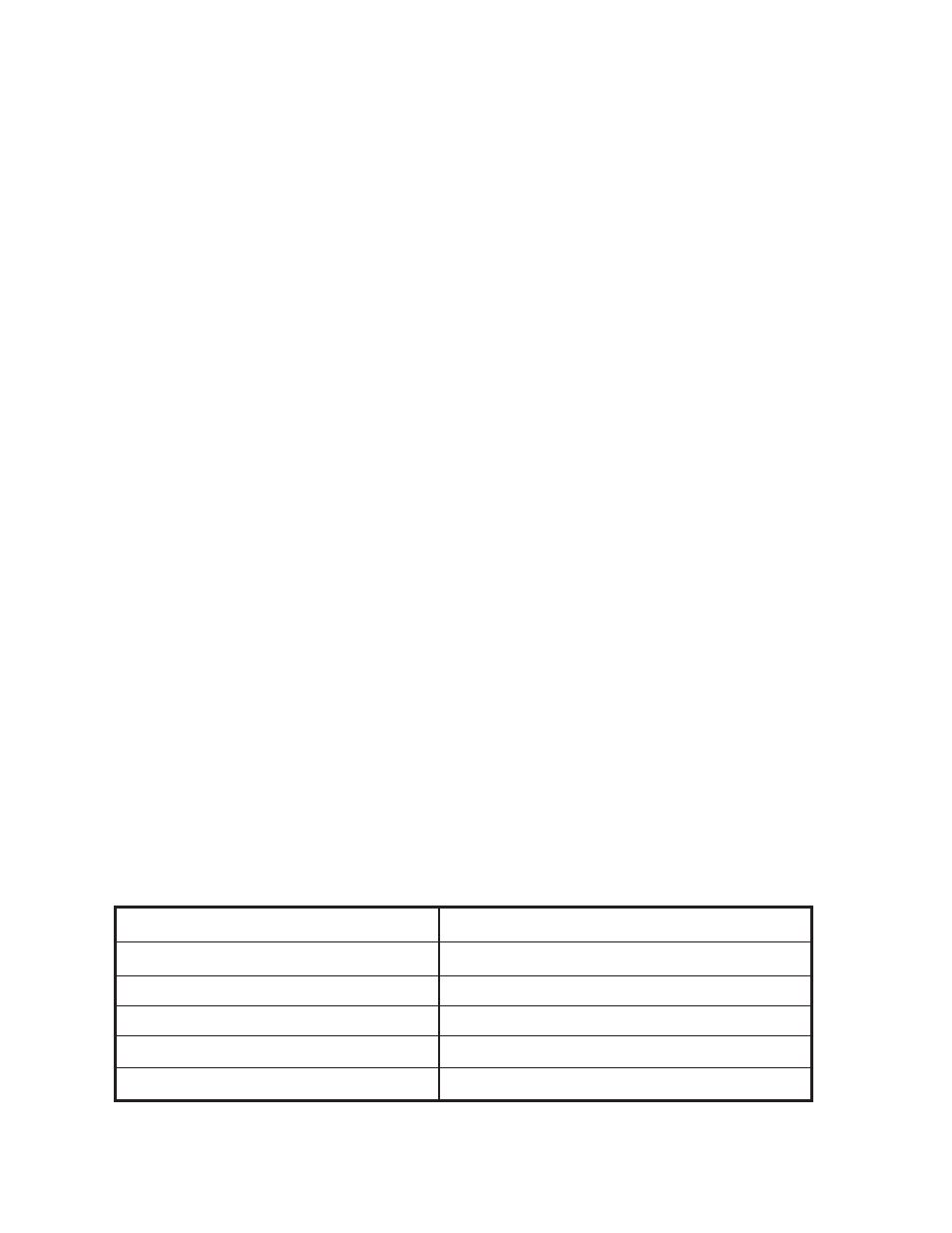

TORQUE REQUIREMENTS

CONNECTION

TORQUE IN POUND MEASURES

AC and PV breakers

to 22 inch-lbs = 2.5 Nm

DC shunt

to 15 foot-lbs = 20.4 Nm

DC battery connections

to 10 foot-lbs = 13.6 Nm

FX’s DC Terminals

to 10 foot-lbs = 13.6 Nm

FX’s AC Terminals

to 30 inch-lbs = 3.38 Nm

Table 1 Torque Values for Installation

AC

Follow these steps to wire the FX to your system:

1. Shut all AC breakers off or remove any fuses before connecting any wiring.

2. Shut off all DC breakers, including the PV breakers.

3. With all power off , run lengths of 6 AWG (16.0 mm

2

)

wire between the AC Wiring Compartment

Board AC out terminals and suffi

cient over current protection via an AC circuit breaker whose

ampacity matches or exceeds the maximum AC input current of the FX model used in the system

(see FX product specifi cations). The breaker should be installed inside of a metal chassis such as

OutBack’s FLEXware series or an existing panel.

4. With the over current protection connected, run lengths of 6 AWG (13.3 mm

2

) wire between the

AC Wiring Compartment Board AC IN terminals and the AC input breaker. The breaker should be

installed inside of a metal chassis such as OutBack’s FLEXware series or an existing panel. The AC

input hot conductor must be supplied through an AC branch-rated circuit breaker whose ampacity

matches or exceeds the maximum AC input current of the FX model used in the system (see FX

product specifi cations)

DC

• Use crimped and sealed copper ring terminal lugs with 5/16” (8 mm) hole or compression-type lug to

connect battery cables to DC terminals. Soldered cable lugs are also acceptable.

• Use recommended cable sizes (see page 36) to reduce losses and ensure high performance of FX (smaller

cables can reduce performance and possibly damage the unit).

• Keep cables together (e.g., using a tie-wrap) as much as possible.

• Ensure cables pass through the same knockout and conduit fi ttings to allow inductive currents to cancel.