Gm hi-tech kickdown kit installation instructions – Lokar GM Hi-Tech Kickdown Kit User Manual

Page 2

Building American Quality… With A Lifetime Warranty!

TOLL FREE 1-877-469-7440 • [email protected] • www.lokar.com

®

GM Hi-Tech Kickdown Kit Installation Instructions

For TH350, 700-R4, TH200, TH200-4R, and 4L60

For TH350, 700-R4, TH200, TH200-4R, and 4L60

INS0003 Rev. 08/05/2014

Page 2

© 2005 Lokar, Inc.

GM Hi-Tech Kickdown Kit Installation Instructions

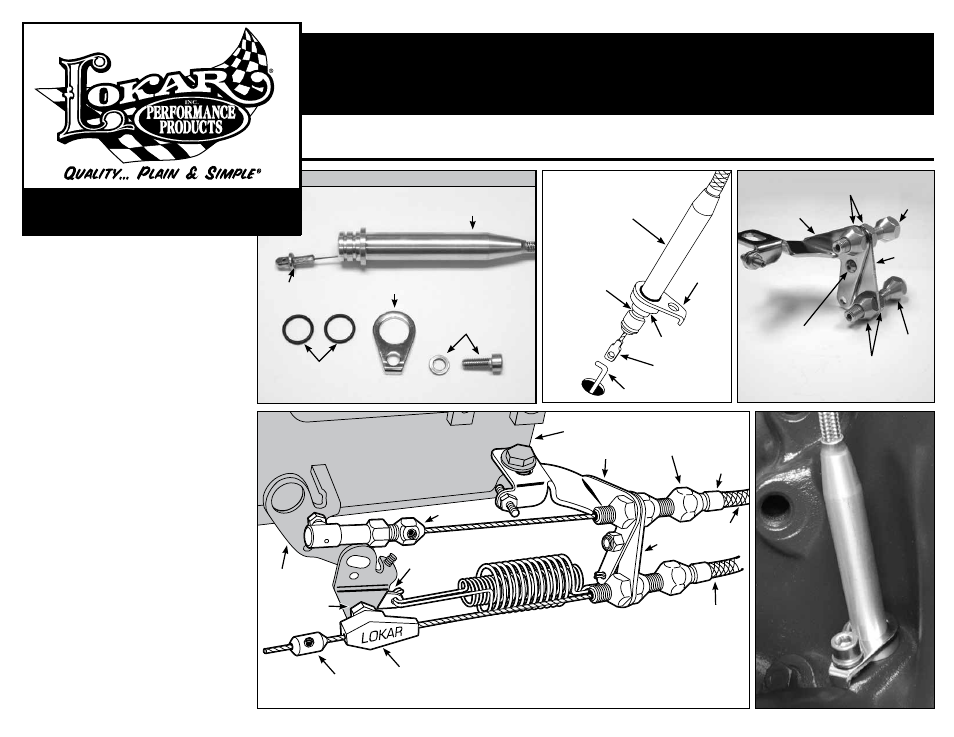

Step 6: The tear drop will be attached to the carburetor throttle arm

by the hex carb fitting. Separate the hex carb fitting from the

kickdown throttle body fitting. Install the hex carb fitting and

the tear drop onto the carburetor throttle arm as shown in

Fig.

6. Hook the springs to the tear drop and tighten the nylock

nut on the hex carb fitting. Then back the nylock nut off just

enough that the tear drop can pivot freely.

Step 7: Remove the kickdown cable housing from the transmission.

Re-install the inner wire into the kickdown cable housing.

Step 8: On the trans tube at the transmission end of the kickdown

cable there will be either one or two o-ring grooves. TH350

& TH200 use one o-ring, and the 700-R4, TH200-4R, and

4L60 use two o-rings. Lightly lubricate the kickdown cable

o-ring(s) with clean transmission fluid and slide the o-ring(s)

into the groove(s) on the trans tube. To help prevent leakage

add a small amount of silicone sealant (RTV) around the

trans tube above the top o-ring.

Fig. 3

Step 9: Insert the hook on the transmission kickdown rod into the hole

in the cable end. Install the trans tube into the transmission,

and secure with the tube hold down clip and bolt.

Step 10: Before connecting the kickdown cable to the carburetor,

make sure that the throttle linkage is properly adjusted.

Verify at the carburetor that the throttle is wide open while

you have a helper hold the accelerator pedal to the floor.

Once you are sure that the throttle linkage is adjusted

correctly, slide the kickdown throttle body fitting onto the

kickdown cable inner wire, and connect the kickdown throttle

body fitting to the hex carb fitting.

Step 11: This step will also be much easier with a helper. Slide the

kickdown cable end stop onto the inner wire. Move the

throttle to wide open and hold it there while pulling the

kickdown inner wire as tight as possible. Slide the cable

end stop up against the kickdown throttle body fitting and

tighten the set screw using the supplied 5/64" Allen wrench.

Release the throttle. When the kickdown cable is properly

adjusted you should be able to open the throttle to the wide

open position without interference from the kickdown cable;

and with the throttle wide open, you should not have any

slack in the kickdown cable.

Double check to be sure that all carburetor, throttle and

kickdown linkage operates freely without binding, then test

drive. Once the kickdown cable is correctly adjusted and

operating properly you can cut off the excess inner wire,

leaving about 1/2" extending beyond the cable end stop

to allow for future adjustment if needed. Final installation

should look like

Fig. 6 and Fig. 7.

Fig. 3

Fig. 4

Fig. 5

Tube Hold

Down Clip

M6 Metric

Socket Head

Bolt and Lock

Washer

O-Rings

Cable

End

Transmission End, TH200-4R, 700-R4, 4L60

Kickdown Rod

Cable End (will vary

by application)

Put Silicone Here

(Step 8)

Tube Hold

Down Clip

O-Ring Groove(s) -

TH350 & TH200

Shown, There are Two

O-Rings on TH200-4R,

700-R4, and 4L60

Trans Tube

Trans Tube

Carburetor Bracket

(not included)

Adjuster Nuts

(not included)

Throttle Cable

Adjuster

(not included)

Kickdown

Mounting

Bracket

Kickdown

Cable

Adjuster

Adjuster

Nuts

#8-32 x 1/2"

Button head Bolt

with Nylock Nut

Fig. 6

Fig. 7

Kickdown Kit shown installed with Lokar Throttle

Cable (not included) and Lokar Carburetor Bracket

and Springs (not included)

Kickdown

Cable

Housing

Throttle

Cable

Housing

Ferrule

Cable

Adjuster

Carburetor

Bracket

Carburetor

Base

Carburetor

Throttle Arm

Kickdown

Mounting

Bracket

Tear Drop

Cable End Stop

Kickdown

Throttle Body

Fitting

Hex Carb

Fitting

Carb End