Lokar GM Hi-Tech Kickdown Kit User Manual

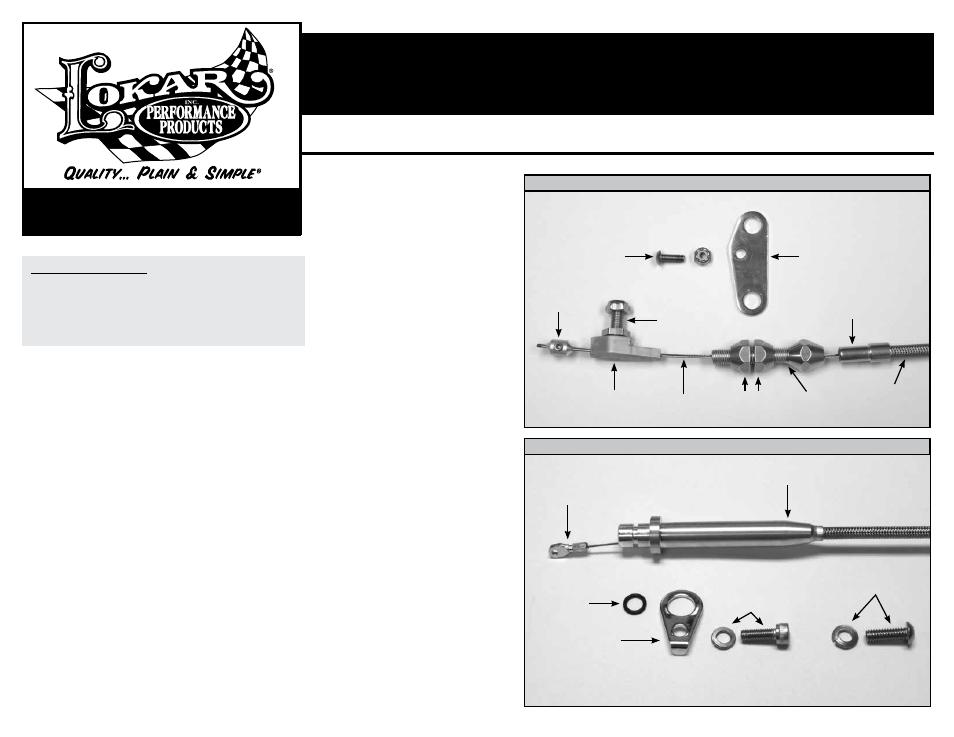

Gm hi-tech kickdown kit installation instructions, Fig. 1 fig. 2

Building American Quality… With A Lifetime Warranty!

General Installation Notes:

Please read these instructions completely before beginning the instal-

lation. If you have any questions please call.

Before beginning the installation, disconnect the negative battery

cable and use wheel chocks to block the vehicle's wheels.

We recommend using anti-seize lubricant on all aluminum threads.

NOTE: This Lokar Kickdown Kit is designed to be installed with a Lokar

Carburetor Bracket and Springs, part # SRK-4000 (not included, available

separately). The Lokar Kickdown Cable is designed to be cut-to-fit.

Refer to Figs. 1, 2 and 3 for the component names.

Step 1: Remove the cable end stop, kickdown throttle body fitting, and

kickdown cable adjuster from the new Lokar kickdown cable. If you

have the braided stainless steel housing, make sure you

DO NOT remove

the ferrule from the cable housing if the cable housing is braided

stainless steel. Leave the kickdown mounting bracket on the kickdown

cable adjuster. Remove the inner wire from the cable housing.

Step 2: From the engine end of the kickdown cable housing, install the tube

hold down clip onto the cable housing with the lip pointed downwards,

and slide it down to the trans tube at the end of the cable housing.

Temporarily install the cable housing into the transmission without the

o-ring(s) and inner wire. Loosely install the bolt for the tube hold down

clip, to keep the cable housing from accidentally coming out of the

transmission.

Fig. 4

Note: TH200 and TH350 transmissions could have come with either

a standard or a metric bolt for the trans tube hold down clip. For

those applications, we have included both a standard 1/4"-20 and a

metric M6 bolt and lock washer for the trans tube hold down clip. The

standard 1/4" – 20 bolt has a rounded button head, and the metric

M6 bolt has a square-shouldered socket head.

Fig. 2 The TH200-4R,

700-R4, and 4L60 will only have a metric bolt and washer in the kit.

Step 3: If the throttle cable has already been installed, disconnect the

throttle cable from the carburetor. If the engine already has a Lokar

Carburetor Bracket installed, remove the throttle cable adjuster. Leave

the carburetor bracket in place. If the engine does not have a Lokar

Carburetor Bracket already installed, install one now, following the

installation instructions that were provided with the Lokar Carburetor

Bracket.

TOLL FREE 1-877-469-7440 • [email protected] • www.lokar.com

®

GM Hi-Tech Kickdown Kit Installation Instructions

For TH350, 700-R4, TH200, TH200-4R, and 4L60

For TH350, 700-R4, TH200, TH200-4R, and 4L60

INS0003 Rev. 08/05/2014

Page 1

© 2005 Lokar, Inc.

GM Hi-Tech Kickdown Kit Installation Instructions

Step 4: The kickdown mounting bracket mounts onto

the back side of the Lokar Carburetor Bracket

(not included). The throttle cable adjuster will

pass through the top hole in both the new

kickdown mounting bracket

AND the carburetor

bracket. Position the kickdown mounting bracket

behind the carburetor bracket so that the 5/16"

diameter holes at the top of both brackets are

aligned, the small 3/16" diameter holes near the

center of the two brackets are aligned, and the

kickdown cable adjuster is offset towards the left

side of the vehicle.

Attach the kickdown mounting bracket to the

carburetor bracket using the supplied

#8-32 x 1/2" button head bolt and nylock nut

through the small 3/16" diameter center holes

in both brackets, but do not tighten yet. Insert

the throttle cable adjuster (with the rear nut still

installed) from the rear through the top holes

in both brackets. Position it so that the bracket

is roughly centered in the threaded part of the

cable adjuster. Install the front adjuster nut.

Tighten the throttle cable adjuster nuts, the

button head bolt and nut, and the kickdown

cable adjuster nuts.

Fig. 5

Step 5: Route the cable housing up to the kickdown

cable adjuster.

Make sure that the inner wire

is removed from the cable housing. If the

cable housing is braided stainless steel, slide

the ferrule down the housing towards the

transmission, away from the end that is being

cut.

DO NOT remove the ferrule from the braided

stainless steel housing! If the cable housing is

black universal, remove the ferrule.

Measure the distance between the kickdown

cable adjuster and the tube hold down clip.

Add 1" to the measurement and cut the cable

housing to that length.

If the kickdown cable has a braided stainless

steel housing, wrap tape around the area to

be cut and use an abrasive cutoff saw or fine-

toothed hacksaw. If the kickdown cable has a

black universal housing, cut the cable housing

with heavy duty 8” diagonal cutting pliers or

a hacksaw. Lokar recommends Klein brand

Diagonal Cutting Pliers, # D2000-28 available

at The Home Depot or through W. W. Graingers,

Part # 4A838.

After cutting the cable housing, put the ferrule

back in place at the end of the cable housing.

Insert the cable housing and ferrule into the

kickdown cable adjuster.

#8-32 x 1/2" Button Head

Bolt with Nylock Nut

Kickdown

Mounting

Bracket

Cable End

Stop

Kickdown Throttle

Body Fitting

Cable

End

Trans Tube

O-Ring

Tube Hold

Down Clip

M6 Metric

Socket Head

Bolt and Lock

Washer

1/4"–20 Standard

Button Head Bolt

and Lock Washer

Inner

Wire

Adjuster

Nuts

Kickdown

Cable Adjuster

Cable

Housing

Hex Carb

Fitting

Ferrule

Fig. 1

Fig. 2

Carburetor End

Transmission End, TH200 & TH350