BMR Suspension TAS002 User Manual

Page 5

5

(CONTINUED)

23. Center punch the marks on the frame to provide a drill centerline.

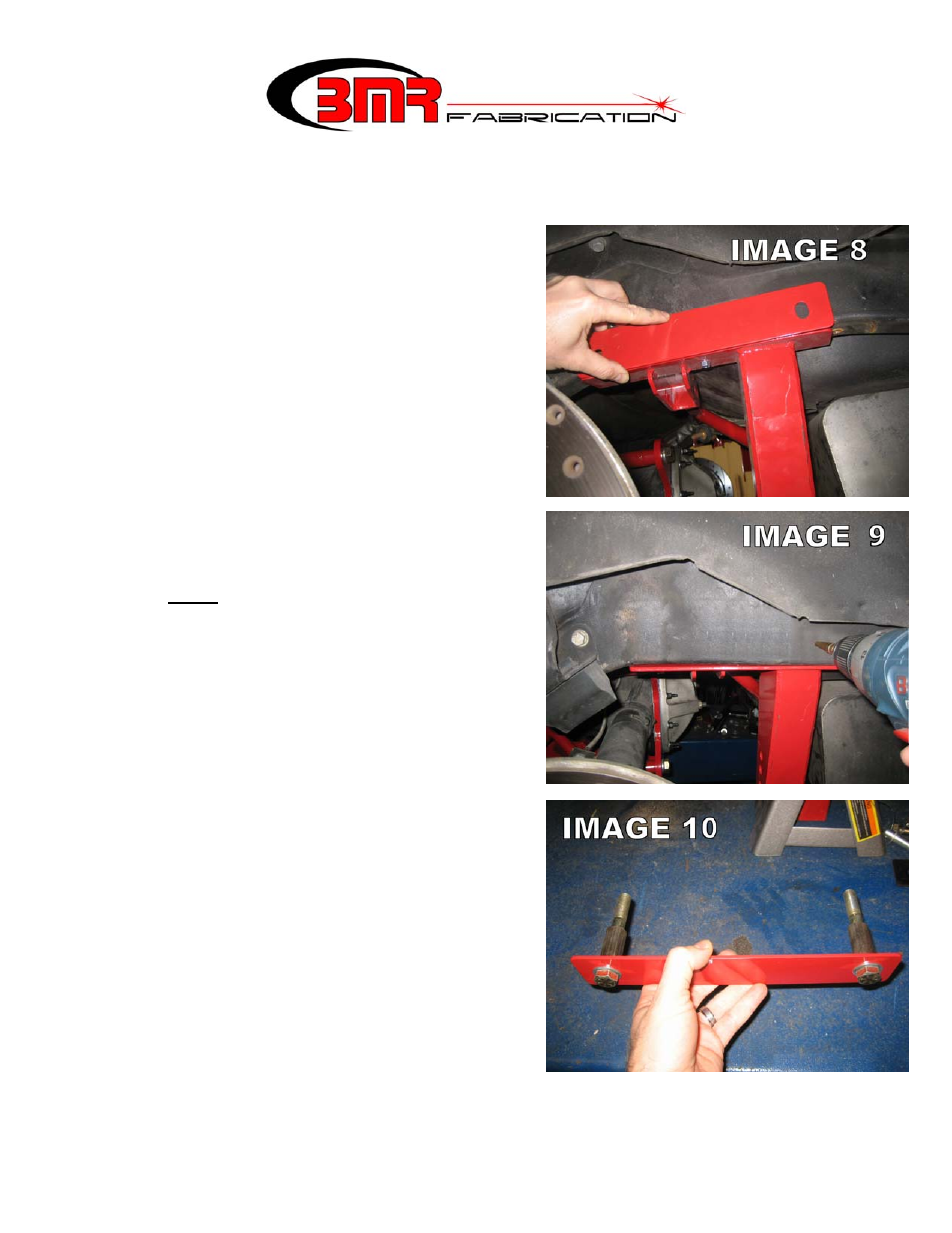

24. The recommended (and easiest) way to drill

through the frame rails is with a step type drill

bit. Using a ½” bit (or step bit) drill through the

outer portion of the frame rail as shown in

Image 9. Take extra care to angle the drill

correctly before drilling through the other side

of the frame rail. Continue drilling through the

frame rail until the bit starts to appear through

the inner bolt holes of the BMR cross-member.

In most cases, the holes in the cross-member

will “self-align” the drill bit, forcing the bit to

center itself in the hole.

25. Once both ½” holes are drilled through the sub

frame, it is necessary to enlarge the outer frame

holes to ¾” to allow insertion of the provided

frame reinforcement inserts. Using either a ¾”

drill bit or a step bit (much easier), enlarge

ONLY the outer holes in the frame rail.

26. Assemble the outer reinforcement plate, frame

inserts and ½” x 3” bolts with stainless washers

as shown in Image 10. Slide the assembly

through the subframe until the bolts protrude

through the BMR cross-member on the inside of

the frame rail. Thread a nut and stainless

washer onto the exposed portion of the bolts and

then tighten these bolts to 80 ft/lbs.

27. Duplicate steps 22-26 for the other side of the

vehicle.

28. Position stands under the vehicle to support the

new BMR 9” axle housing.

29. Place the housing on the stands in such a way

that the housing does not rotate. Center the

housing in the wheel wells.

30. Before proceeding with the rest of the torque

arm installation, it is necessary to install the

third member (pumpkin or center section).

31. Begin by applying a thin bead of black or grey

RTV silicone around the gasket face of the

BMR 9” axle housing then position the gasket

over the studs. Apply another bead on the

outside of the gasket then place the third member over the studs. Tighten all nuts to 40

ft/lbs in a criss-cross pattern. NOTE: the rearend shown in the following images does

not have the third member installed for illustrative purposes.