Frost damage, Water precautions, Plumbing materials to avoid – HP Modular Cooling System User Manual

Page 59

Water quality and leveling requirements, and condensation management 59

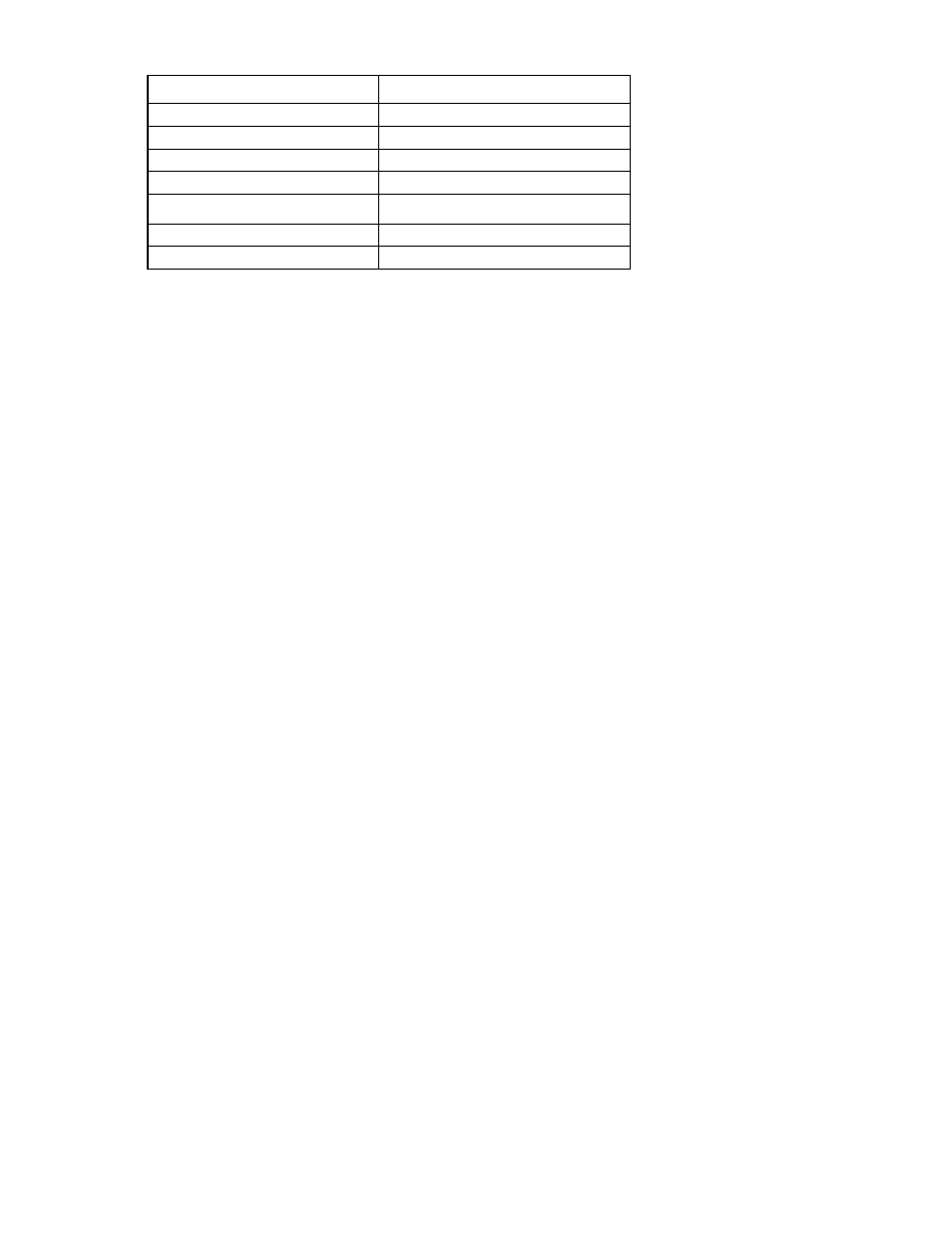

Parameter

Range

Hardness (CaCO

3

), total

<200 ppm

Iron (Fe), total

<3.0 ppm

Manganese (Mn), total

<0.1 ppm

Bacteria

<1000 CFUs/ml

Residue on evaporation

<500 ppm

Turbidity

20

Corrosion inhibitor

Recommended

If your water is out of range, consult a water quality expert.

HP recommends using particulate filtration on the dedicated water supply system connected to the MCS-100

unit.

Frost damage

To avoid frost damage, the water temperature must not be allowed to fall below the minimum permissible

temperature of +4 ºC (+39.2 ºF) at any point in the water cycle.

Before storage or transportation at sub-zero temperatures, the water cycle must be drained completely using

compressed air. Avoid setting the target temperature lower than is necessary because the danger of falling

below the dew point increases as water temperature decreases (condensation buildup). Ensure that the

enclosure is sealed on all sides, and in particular at the cable inlet (condensation formation).

Water precautions

Take the following precautions during the installation of the MCS-100 unit:

•

Before installing the HP Modular Cooling System Hook-Up Kit, ensure that all foreign matter and

particulates are flushed from the system.

•

Evaluate the short-term and long-term system requirements against the available water capacity.

•

Ensure that the chilled water loop is properly designed for liquid cooling systems and is separate from

the sanitary water systems in your building (bathroom, sink, drinking water, and so on).

•

Ensure facility managers understand the additional load being added to the chilled water supply of the

building. Be aware that the added heat load might affect other components being cooled by the chilled

water plant.

Plumbing materials to avoid

Do not use the following materials in a closed water system:

•

Oxidizing biocides

•

Aluminum components

•

Brass components with high levels of zinc

•

Non-stainless steel Iron components