Routine maintenance, Hopper cleaning – Nilfisk-ALTO RS 2200 User Manual

Page 158

ENGLISH

USER MANUAL

36

33019476(3)2010-02 A

RS 2200

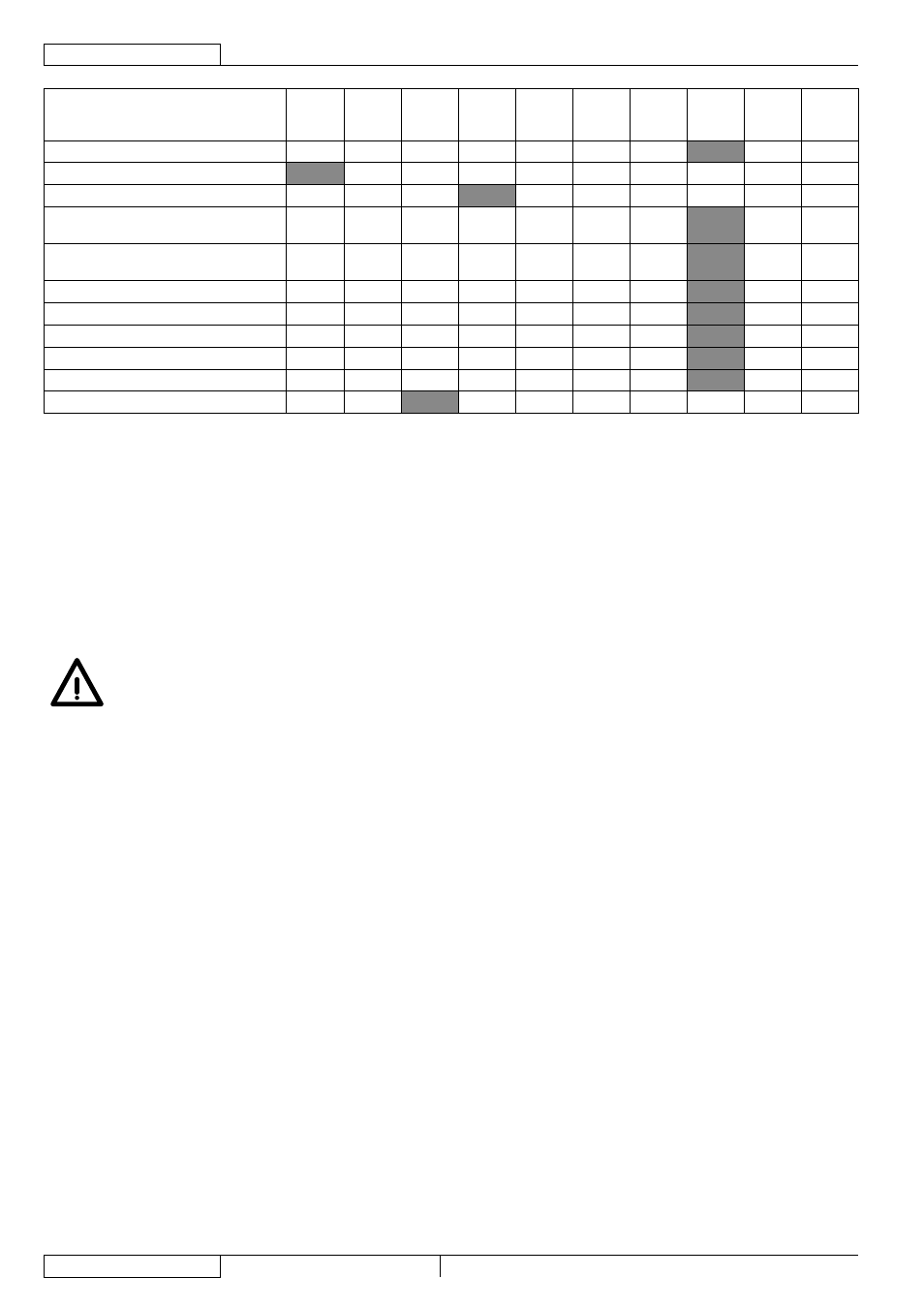

Maintenance

Long

periods

After

every

use

Every

40

hours

Every

150

hours

Every

200

hours

Every

300

hours

Every

500

hours

Every

800

hours

Every

1,000

hours

Every

1,500

hours

Dust control system pump oil change

(6)

Gasket, joint, and valve replacement

(1)(6)

Broom replacement

Suction inlet lower skirt gasket replace-

ment

Suction inlet upper skirt gasket replace-

ment

Suction inlet side gasket replacement

Skirt gasket replacement

Side gasket replacement

Rear door gasket replacement

Branch pipe gasket replacement

Battery terminal check

Every 1,000 hours

(1)

Maintenance to be performed by VM Motori authorised Service Center

(2)

Every 2 years

(3)

Every 2,500 hours

(4)

Under special operation conditions, in dusty environments and with high loads, the oil must be changed every 150 hours.

(5)

For the procedure see the Service Manual, at any Nilfi sk Service Center.

(6)

After the fi rst 50 hours

(7)

Every year

(8)

Contact Nilfi sk Service Centers

(9)

ROUTINE MAINTENANCE

HOPPER CLEANING

WARNING!

Protect body parts (eyes, hair, hands, etc.) properly, when performing cleaning procedures using compressed

air or water gun.

Empty the hopper, drive the machine to the appointed cleaning/washing area, then perform the following procedure:

Engage the parking brake (3, Fig. D).

1.

Lift and open the hopper as shown in the relevant paragraph.

2.

Install the support rod (1, Fig. M) as shown on the relevant paragraph.

3.

Clean the hopper with pressurised water. If using the machine high-pressure washing system, follow the instructions shown in

4.

the relevant paragraph.

Open the cover (4, Fig. Z) by lifting it.

5.

Remove the locking clip (5, Fig. Z) and remove the recycling system protecting fi lter (6).

6.

Wash the fi lter (6) with high-pressure water.

7.

Open the upper inspection doors (7 and 8, Fig. Z) and, with high-pressure water, clean the right side suction protection grid (9)

8.

and the left side suction protection grid (10).

Check if the recycling system is cleaned. With the lowered hooper, run a water jet inside the sleeve (1, Fig. Z); the water must

9.

come out under the cab, near the suction inlet. If this does not occur, clean the recycling system hoses.

With the lifted hopper and under safety conditions, run a water jet inside the sleeve (1, Fig. Z) and have the water come out of

10.

the sleeve (2). Run a water jet inside the sleeve (3, Fig. Z) and have the water come out under the cab, near the suction inlet.