Maintenance, Scheduled maintenance table – Nilfisk-ALTO RS 2200 User Manual

Page 156

ENGLISH

USER MANUAL

34

33019476(3)2010-02 A

RS 2200

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

The following table provides the scheduled maintenance. The intervals shown may vary according to particular working conditions,

which are to be defi ned by the person in charge of the maintenance.

WARNING!

To perform maintenance procedures turn off the machine (remove the ignition key) and turn the battery release

switch (37, Fig. G) to OFF (see Fig. X).

Moreover, read carefully the instructions in Safety chapter before performing any maintenance procedure.

WARNING!

When performing maintenance procedures which require hopper lifting, the support rod (1, Fig. M) must be

engaged. See the procedure in Hopper Support Rod Installation paragraph.

CAUTION!

Do not perform maintenance procedures when the machine lifting device is activated (leaf springs at the end of

stroke).

NOTE

When performing maintenance procedures, use only original spare parts.

NOTE

The display (32, Fig. E) is programmed to show an expired or nearly expired maintenance by means of the symbol

.

Maintenance must be performed at 150 and 500 hours (see Display Functions paragraph).

All scheduled or extraordinary maintenance procedures must be performed by qualifi ed personnel, or by an authorised Service

Center.

This Manual contains the Scheduled Maintenance Table and describes only the easiest and most common maintenance

procedures.

For other maintenance procedures contained in the Scheduled Maintenance Table or for extraordinary maintenance procedures see

the Service Manual that can be consulted at any Service Center.

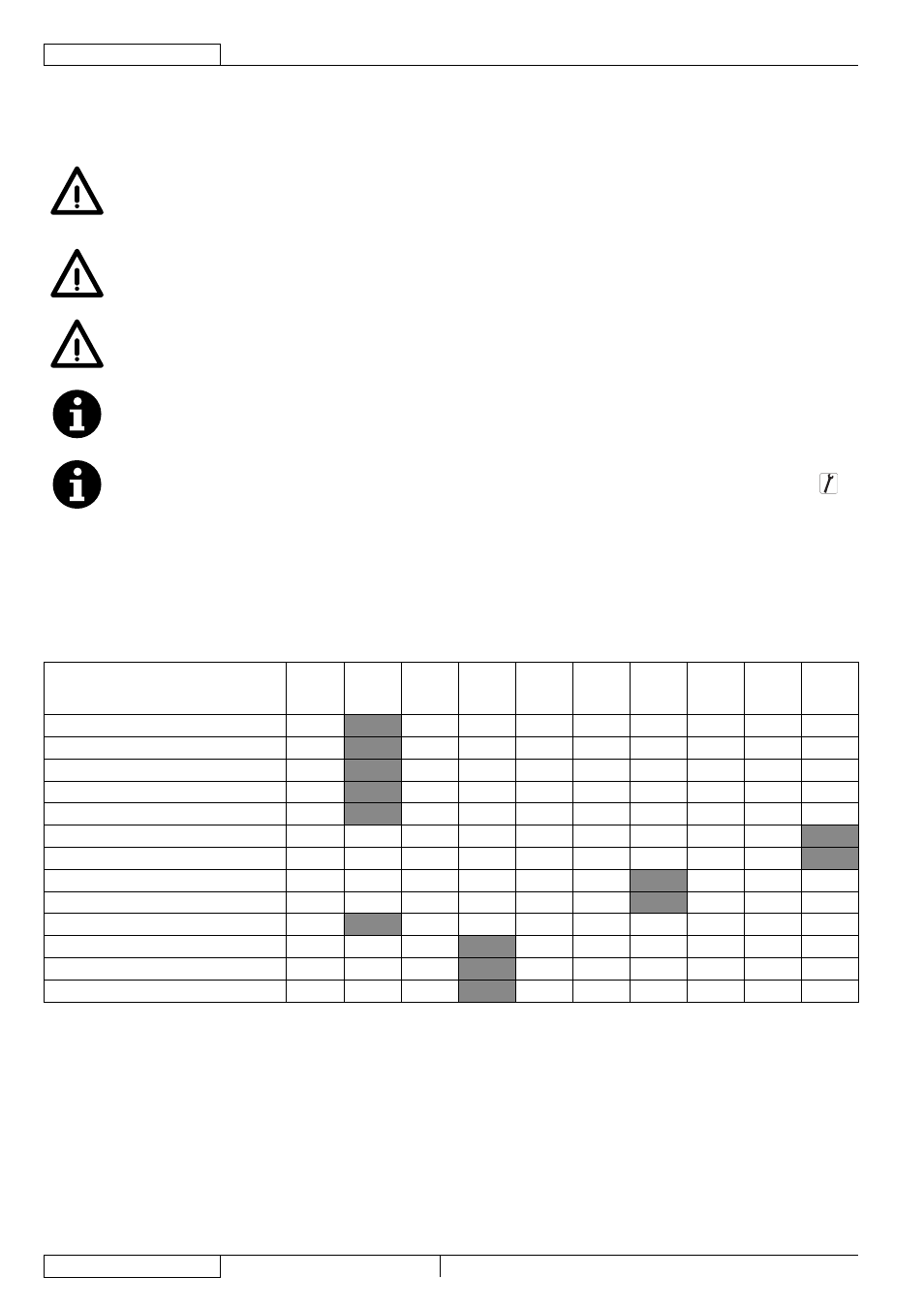

SCHEDULED MAINTENANCE TABLE

Maintenance

Long

periods

After

every

use

Every

40

hours

Every

150

hours

Every

200

hours

Every

300

hours

Every

500

hours

Every

800

hours

Every

1,000

hours

Every

1,500

hours

Engine oil level check

Brake fl uid level check

Hydraulic system oil level check

Engine coolant level check

Engine air fi lter cleaning

Air fi lter cyclone block cleaning

Particulate fi lter cleaning

Particulate fi lter regeneration

(9)

Engine air fi lter replacement

Combined radiator fi n check

Combined radiator fi n cleaning

Coolant line check

(6)(7)

Engine cylinder head tightening

(2)