Caution, Sewing hook-and-loop fastener, If the fabric does not fit under the presser foot – Brother Innov-is V5 User Manual

Page 76: If the fabric does not feed

SEWING

S-8

■ If the Fabric does not Fit under the

Presser Foot

If the presser foot is in the up position, and you are

sewing heavyweight or multiple layers of fabric

which do not fit easily under the presser foot, use

the presser foot lever to raise the presser foot to its

highest position. The fabric will now fit under the

presser foot.

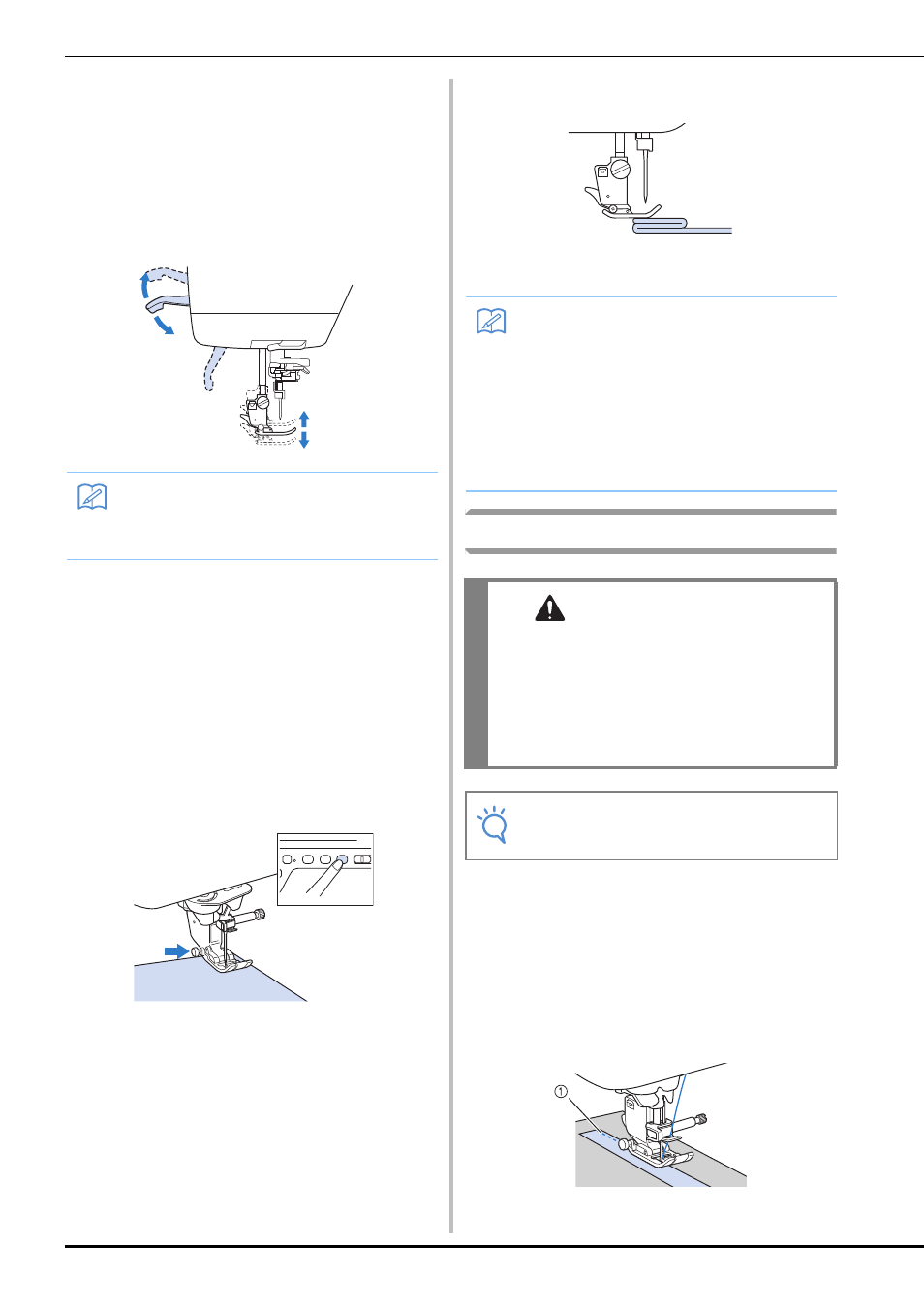

■ If the Fabric does not Feed

If the fabric does not feed when starting to sew or

when sewing thick seams, press the black button on

the left side of presser foot “J”.

a

Raise the presser foot.

b

While keeping the black button on the left

side of presser foot “J” pressed in, press the

“Presser Foot Lifter” button to lower the

presser foot.

c

Release the black button.

→ The presser foot remains level, enabling the fabric to

be fed.

Sewing Hook-and-Loop Fastener

Make sure that the needle passes through the

hook-and-loop fastener by rotating the handwheel

and lower the needle into the hook-and-loop

fastener before sewing. Sew the edge of the

hook-and-loop fastener at a slow speed.

If the needle does not pass through the

hook-and-loop fastener, replace the needle with

the needle for thick fabrics (“Fabric/Thread/Needle

Combinations” of “Basic operations”).

a Edge of the hook-and-loop fastener

Memo

• You cannot use the presser foot lever after

the presser foot has been raised using the

“Presser Foot Lifter” button.

Memo

• Once the trouble spot has been passed, the

foot will return to its normal position.

• When “Automatic Fabric Sensor System”

(Automatic Presser Foot Pressure) in the

machine settings screen is set to “ON”, the

thickness of the fabric is automatically

detected by the internal sensor so the fabric

can be fed smoothly for best sewing results.

(see page S-17 for details.)

CAUTION

• Do not use adhesive backed hook-and-loop

fastener designed for sewing. If the adhesive

sticks to the needle or the bobbin hook race, it

may cause malfunction.

• If the hook-and-loop fastener is sewn with a

fine needle (65/9-75/11), the needle may bend

or break.

Note

• Before starting to sew, baste the fabric and

hook-and-loop fastener together.