5 options, Level b – drying hopper loader only – Sterlco SDAP 90-225 CFM Series Drying and Conveying Systems User Manual

Page 9

SDAP Series PD 2 to PD 4 Drying and Conveying Systems

Page 9

Level B – Drying Hopper Loader Only

; Drying hopper loader with high efficiency centrifugal blower and adjustable convey timer.

; Cartridge type (two stage) air filters for the blower.

; Quick disconnect cable for drying hopper loader material demand switch.

; Pick-up wand and ten (10) foot (3 m) length of vinyl flex hose and clamps.

; Standard take-off compartment (open loop) on discharge of drying hopper.

Level C – Both Machine Loader And Drying Hopper Loader

; Features of both level A and level B, including closed loop dry air convey take-off

compartment.

1-5 Options

Options can tailor your Sterling SDAP system to meet the exact requirements of the drying task

being performed.

; 13X desiccant.

; Aftercoolers for high and low temperature applications.

; Seven day timer to allow programmable dryer startup.

; Audible/visual critical alarm.

; Fusing for blowers and heaters.

; Dirty Filter indicator for each individual blower.

; Proportioning valve for the drying hopper loader (Levels B and C).

; Stainless steel convey hose (Levels A and C).

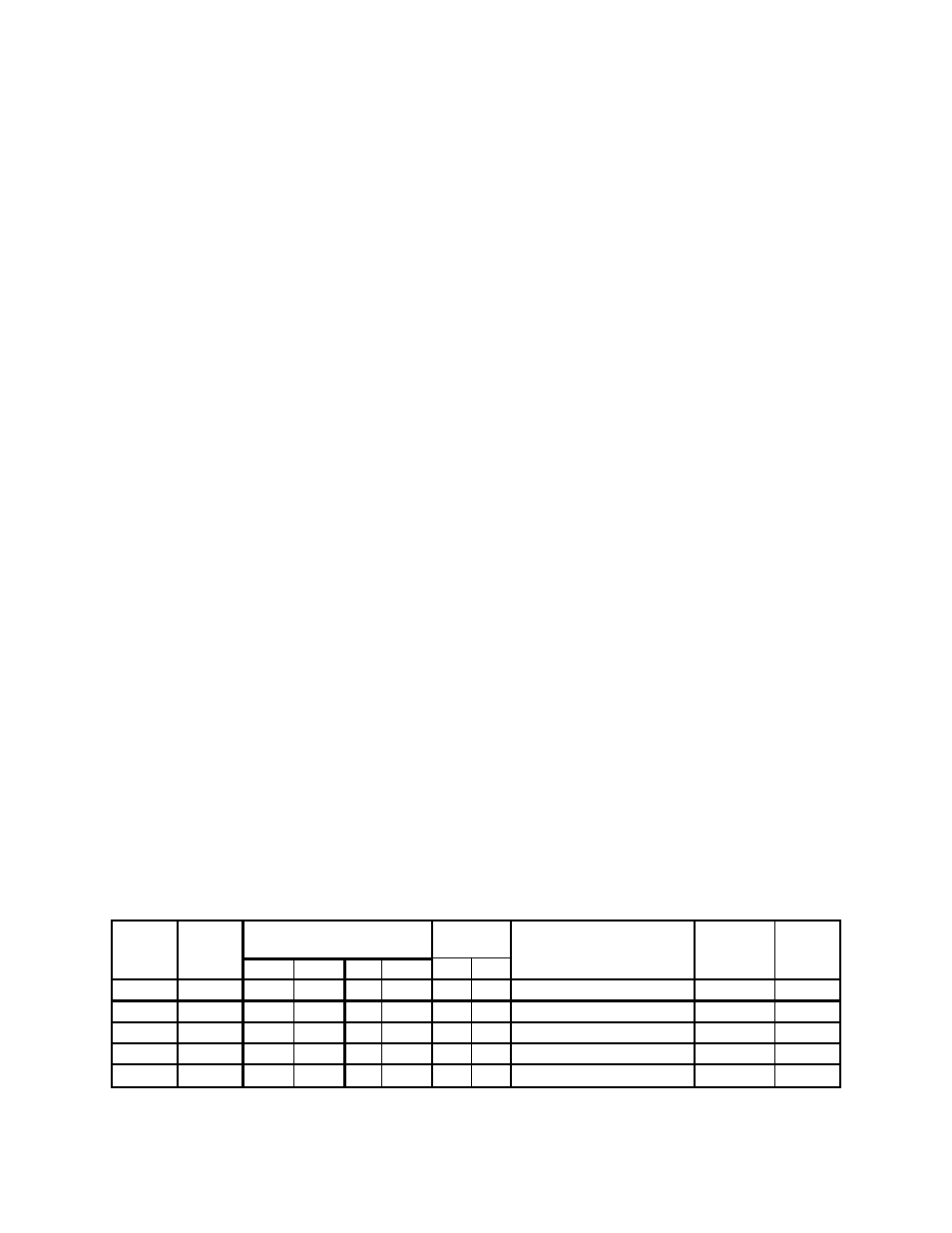

Figure 1

SDAP PD-2 through PD-4 Specifications

Dryer

Hopper

Process

Output

Full

Model model

size

air

flow

temperature

Standard

load

number number cu. ft. liters lbs. Kg cfm cmh

range

voltage amps

c

PD-2 SDA90 6.0 160

200

90.8

90

153 140

°-400° F (60°-204°C) 460/3/60 24

PD-3 SDA100

12.0 320

400

181.6 100

170 185

°-400° F (85°-204°C) 460/3/60 27

PD-4A SDA150

12.0 320 400

181.6

150 255 160

°-400° F (71°-204°C) 460/3/60 38

PD-4B SDA150

17.0 452 600

272.4 150 255 160

°-400° F (71°-204°C) 460/3/60 38

PD-4C SDA225

23.0 612 800

363.2 225

382 160

°-400° F (71°-204°C) 460/3/60 48

c Level C (Machine Loader and Drying Hopper Loader)