Sterlco SDAP 90-225 CFM Series Drying and Conveying Systems User Manual

Page 42

Page 42

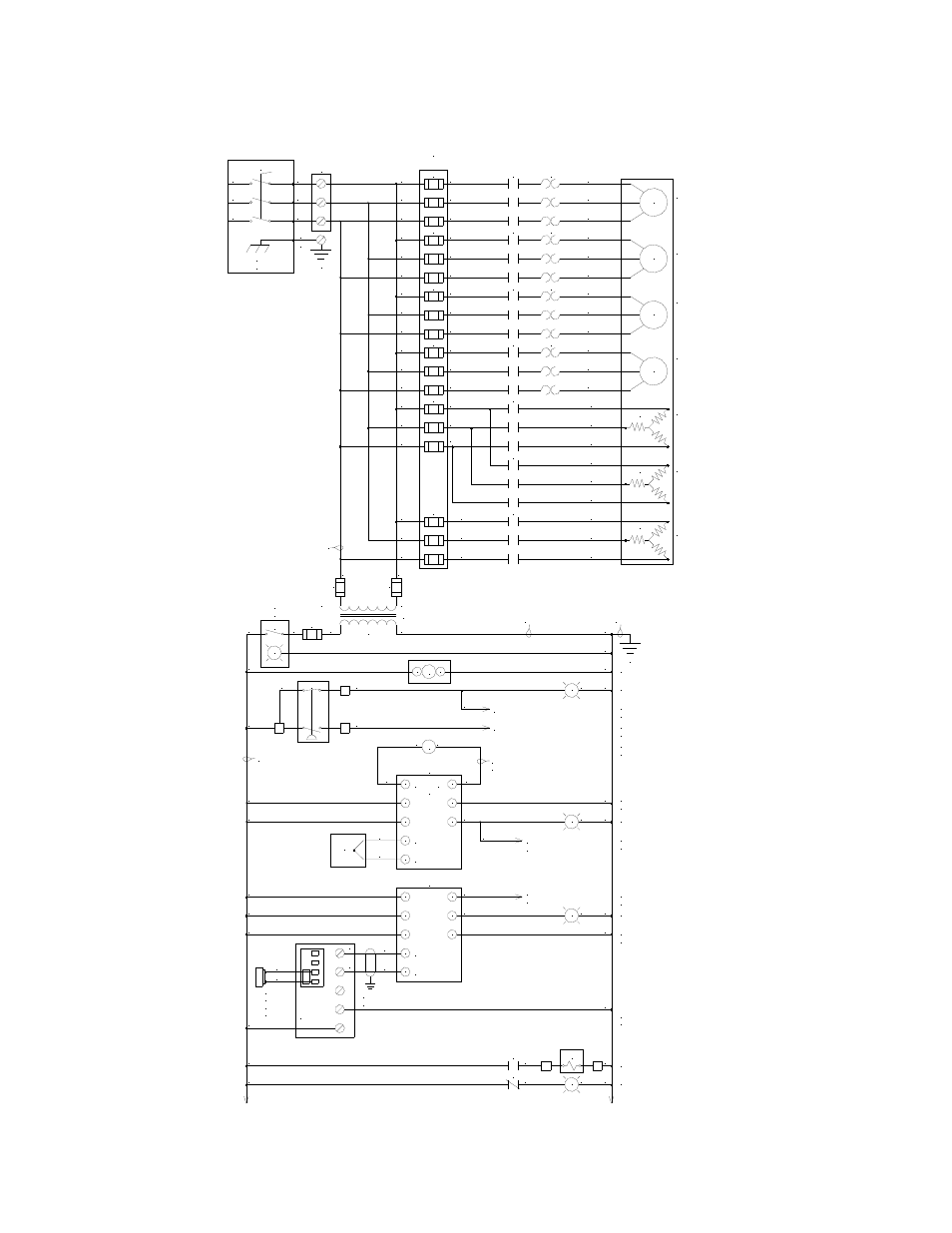

SDAP Series PD 2 to PD 4 Drying and Conveying Systems

Figure 15

Typical PD2-4 Electrical Schematic, Drawing 1

12

10

12

POINT

& CABLE

SENSOR

4

4

4

DPCB

CABLE (22GA, 2COND)

4

4

BLK

WHT

DEW

4

SHIELDED

-

+

-

13

7

+

4

12

6

9

11

2CNTL

-

+

7

6

4

4

18 GA RED

4

4

4

+

+

11

2

4

(NPN)

7

1CNTL

-

6

5

-

1

2

14

15

"LEFT BED IN REGEN"

BOARD & SENSOR

DEW POINT CONTROL

BED SHIFT SOLENOID

2

2

2

7-DAY TIMER (OPTIONAL)

HIGH TEMP PROCESS AIR

"HIGH TEMP PROCESS AIR"

AUDIBLE ALARM (OPTIONAL)

TO PLC INPUT I/4

TO PLC INPUT I/8

11

5

10

9

(LINE 166)

(LINE 174)

"HIGH DEW POINT"

2

CONTROLLER

DEW POINT DISPLAY/

2

SWITCH INPUT

DEW POINT BED

PLC INPUT

TO PLC INPUT I/7 (LINE 172)

TO PLC INPUT I/1 (LINE 158)

18GA BLUE

9

3

5

8

24VDC

5

SOLID STATE

PROCESS TEMPERATURE

CONTROLLER

2

2

RELAY

PLC INPUT

LOW AIR PLC INPUT

BLOWER ENABLE

"LOW COMPRESSED AIR"

2

2

BRANCH FUSING

(OPTIONAL)

BLACK POWER WIRE

SEE ENCL. LAYOUT

FOR GAUGE SIZE

4

ON/OFF

3

SYSTEM

1L3

1L1

1

120VAC

8L3

2

8L1

1L3

1L2

1L1

1L1

1L2

1L3

1L3

1L2

1L1

1L3

1DBLK

GROUND

EARTH

LUG

GRD

1DISC

L3

L2

L1

1L3

1L2

1L1

1L3

1L2

1L1

1L2

1L1

1L3

1L2

1L1

PROCESS

HEATER

DRYING

HOPPER

CONVEY

BLOWER

(OPTIONAL)

RIGHT BED

REGENERATION

HEATER

LEFT BED

REGENERATION

HEATER

18 GA WHITE

18 GA GRN/YEL

2

2

MACHINE

LOADER

CONVEY

BLOWER

REGENERATION

BLOWER

PROCESS

BLOWER

PANEL

GROUND

1FU

2L1

2L2

2L3

1M

10L

1T1

1T2

1T3

1MTR

2FU

3L1

2L2

2L3

2M

20L

2T1

2T2

2T3

2MTR

3FU

4L1

4L2

4L3

3M

30L

3T1

3T2

3T3

3MTR

4FU

5L1

5L2

5L3

4M

40L

4T1

4T2

4T3

4MTR

5FU

6L1

6L2

6L3

1C

1H1

1H2

1H3

1HTR

2C

2H1

2H2

2H3

2HTR

6FU

3C

7L1

7L2

7L3

3H1

3H2

3H3

3HTR

7F

U

G

1PS

1SSR

1TMR

8FU

1RS-LT

7F

U

1T

GRD

1LT

R

[+] YEL

[-] RED

TC

TYP

E

K

2LT

R

3LT

A

4LT

G

1SOL

1CR

1CR