Preventive maintenance checklist, Sterling sdap drying/conveying systems – Sterlco SDAP 90-225 CFM Series Drying and Conveying Systems User Manual

Page 69

SDAP Series PD 2 to PD 4 Drying and Conveying Systems

Page 69

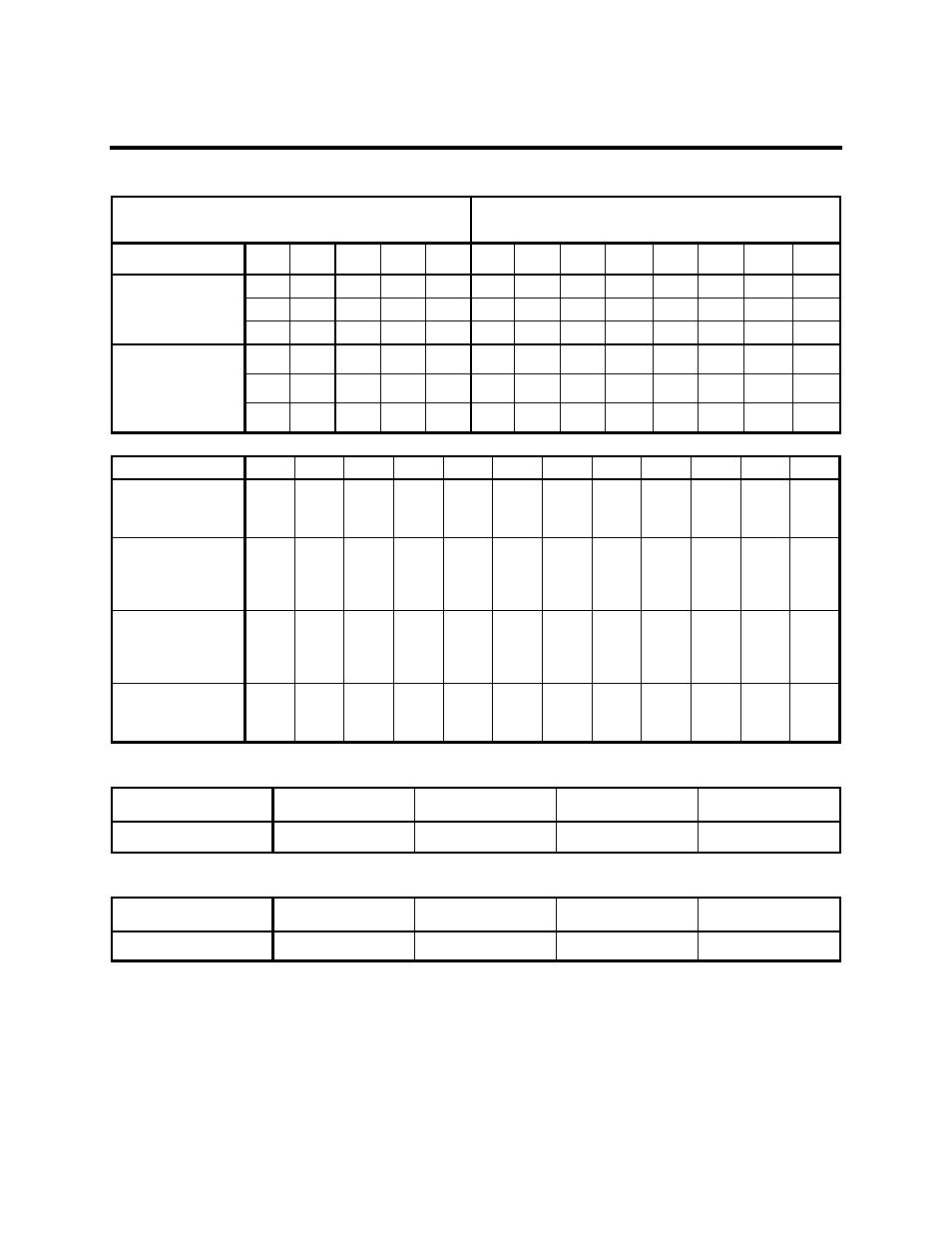

Preventive Maintenance Checklist

Sterling SDAP Drying/Conveying Systems

System model #

Serial #

Every week

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Date/

By

Inspect all filters for

wear, replace/clean

if dirty or worn.

Check air regulator

to make sure pres-

sure is 60-80 psi

(413.7 to 551.6 kPa

/4.1 to 5.5 bars). (If

applicable)

Every month

Jan Feb Mar

Apr May

Jun

Jul Aug

Sep Oct Nov

Dec

Lock out electrical

power and inspect

electrical wiring for

integrity.

Lock out electrical

power and check

heater elements for

continuity using an

ohmmeter.

Check dew point and

temperature tracking

with an external dew

point monitor and

pyrometer.

Visually inspect the

shifting of the airflow

valve during one

cycle.

Every year

Next scheduled

inspection

Actual inspection

Date/By

Next scheduled

inspection

Actual inspection

Date/By

Inspect desiccant. Replace

if brown or broken.

Every two years

Scheduled

replacement date

Actual replacement

Date/Work done by

Scheduled

replacement date

Actual replacement

Date/Work done by

Replace desiccant.

- Photocopy this page for your maintenance records -