5 flange mounting tips, 6 installing material/vacuum tubing, Important – Sterlco SDAP 90-225 CFM Series Drying and Conveying Systems User Manual

Page 18

Page 18

SDAP Series PD 2 to PD 4 Drying and Conveying Systems

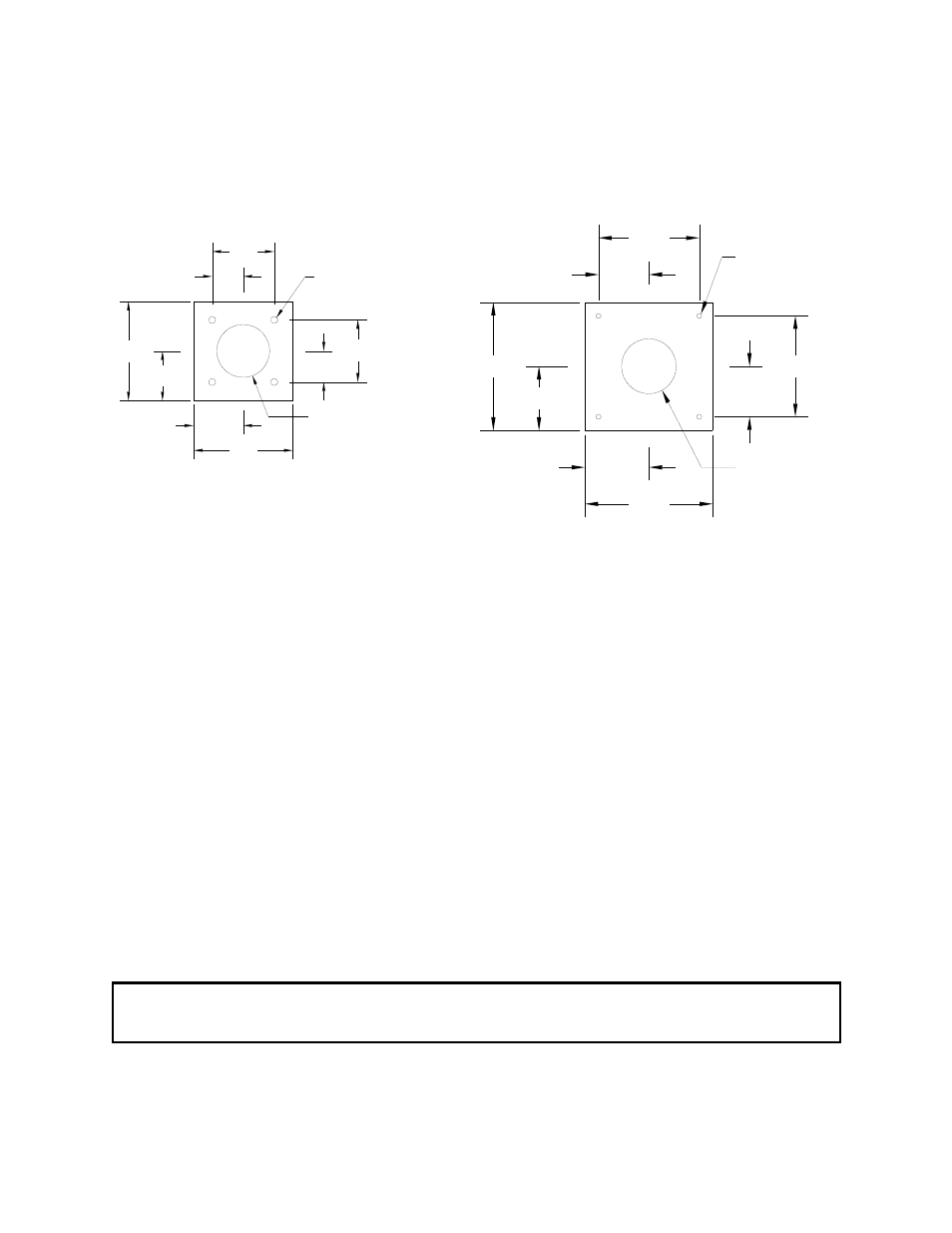

Figure 5

Sight Glass Hopper Flange Templates

Models SGV011, SGV012

Optional Models SGV031/032

2.50"

2.50"

4.00"

1.25"

2.00"

2.00"

1.25"

2.125 (2 1/8") hole

4.00"

(4 places)

0.28" (9/32") hole

(7 mm)

(5.5 cm)

6 cm

3 cm

10 cm

5 cm

5 cm

10 cm

3 cm

6 cm

3-5 Flange Mounting Tips

; Run a bead of silicone sealant around the mounting flange before seating the vacuum hopper.

This makes a better seal.

; Use rivets to mount the hopper. Nuts and bolts can loosen, fall off, and damage process

equipment.

; Check across the mounting flange with a bubble level. A level installation is important for

proper hopper dump.

; Properly ground all sight glass loaders and vacuum hoppers.

3-6 Installing Material/Vacuum Tubing

Note: System capacity is directly affected by the pressure drop in the overall system, such as

number of material line bends, footage of pipe, Y-tubes, T-tubes, etc.

Use the minimum effective amount of vinyl flex hose to maximize material line efficiency. Keep

material lines as straight as possible.

Important!

Vacuum leaks anywhere in your system reduce capacity.

3.50"

7.00"

5.50"

2.75"

7.00"

3.50"

5.50"

2.75"

3.00" (7.75 cm) hole

(4 places)

0.28" (9/32") hole

(7 mm)

14 cm

7 cm

18 cm

9 cm

14 cm

7 cm

18 cm

9 cm