6 the closed loop drying system – Sterlco SDAP 90-225 CFM Series Drying and Conveying Systems User Manual

Page 10

Page 10

SDAP Series PD 2 to PD 4 Drying and Conveying Systems

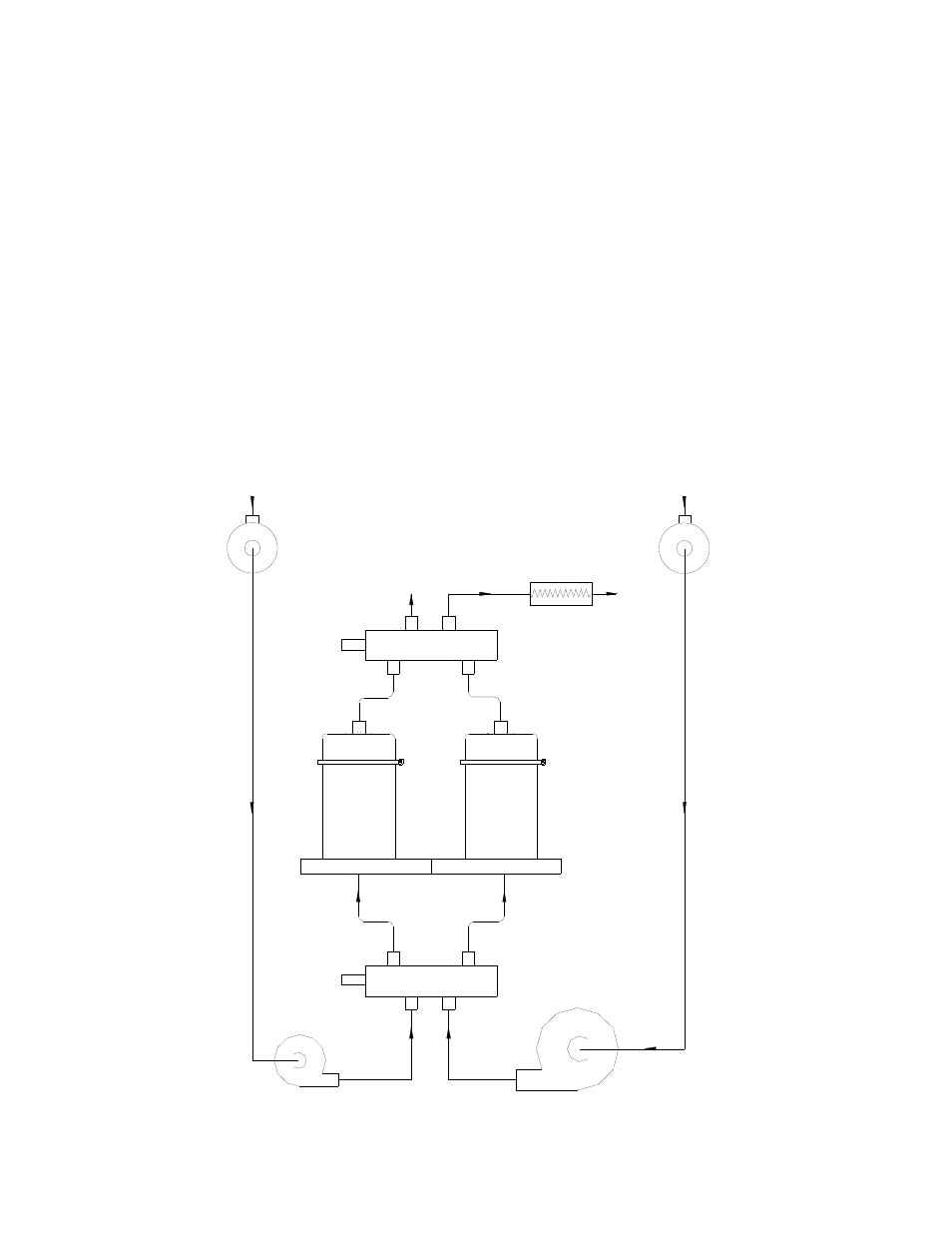

1-6 The Closed Loop Drying System

Sterling dryers force hot, dry air through the resin in the drying hopper where the air picks up

moisture from the material and is drawn back to the dryer.

In the dryer, a desiccant bed strips moisture from the air. The dryer then re-heats dried process

air, and sends it back into the drying hopper to dry material again.

This system is a closed loop, because ambient (outside) air is never introduced into the process

air. Sterling uses the closed loop system, because the process air is typically much drier than

ambient air, even after carrying moisture out of the plastic resin. Recycling process air maintains

drying efficiency at a consistently high level.

Figure 2

Dryer Air Flow Diagram

Ambient

Regen

filter

Regen

bleed

Process air

heater

From

drying hopper

Process

filter

To drying

hopper

Upper valve

Desiccant

beds

Desiccant

beds

Regen heater

Regen heater

Lower valve

Regen blower

Process blower