Service and maintenance – NORD Drivesystems B2050 User Manual

Page 34

5. Service and maintenance

-34- B2050-GB-0613

www.nord.com

5. Service and maintenance

5.1 Service and Maintenance Intervals

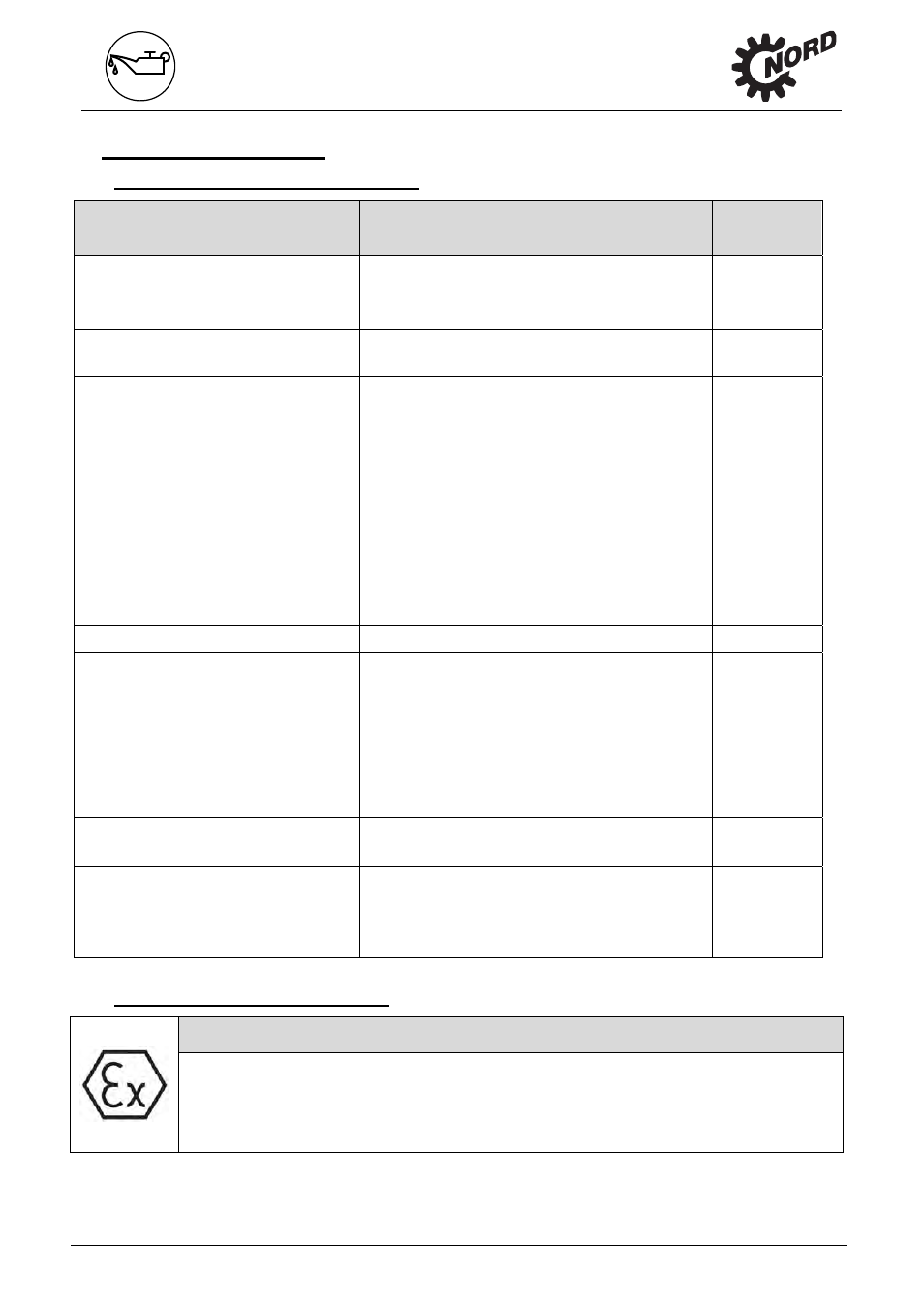

Service and Maintenance Intervals

Service and Maintenance Work

Information –

see Section

Weekly

or every 100 operating hours

- Check the gear unit for unusual running noises

and/or vibrations

- Perform a visual inspection for leaks

5.2

5.2

At least once per month

- Check the cover and the attachment adapter for

dirt

5.2

Every 2500 operating hours,

at least six-monthly

- Visual inspection of rubber buffer

- Visual inspection of hose

- Visual inspection of temperature sticker

- Remove dust

(only for category 2D)

- Check oil level

- Re-grease

(for agitator bearings Option VLII / VLIII)

- Check oil filter

- Clean or replace the pressure venting screw

5.2

5.2

5.2

5.2

5.2

5.2

5.2

At least every year

- Check the oil / air cooler for dirt

5.2

For operating temperatures up to 80°C

Every 10000 operating hours, at least

every 2 years

Higher temperatures reduce the oil

change intervals

- Change oil (if filled with synthetic oil, this period

is doubled)

Reduction of lubricant replacement interval

under extreme operating conditions (high

humidity, aggressive environment and high

temperature fluctuations)

- Replace oil filter

5.2

5.2

Every 25000 operating hours,

at least every 5 years

- Replace the shaft sealing rings if worn

- Re-lubrication of the bearings in the gear unit

5.2

5.2

According to the interval specified in

field MI of the name plate

at least every 10 years

(Only for Category 2G and 2D)

- General overhaul

5.2

5.2 Service and Maintenance Work

Danger!

No explosive atmosphere must be present during servicing and repair work. Servicing

and maintenance work must only be performed by qualified specialist personnel.

When cleaning the surface of the gear unit, do not use and procedures or materials,

which could cause electrostatic charging of the surface of the gear unit.