NORD Drivesystems B2050 User Manual

Page 17

3. Assembly instruction,

storage, transport, preparation, installation

www.nord.com B2050-GB-0613

-17-

Danger!

Care must be taken that drive and driven elements attached to the gear unit must also

be ATEX-compliant.

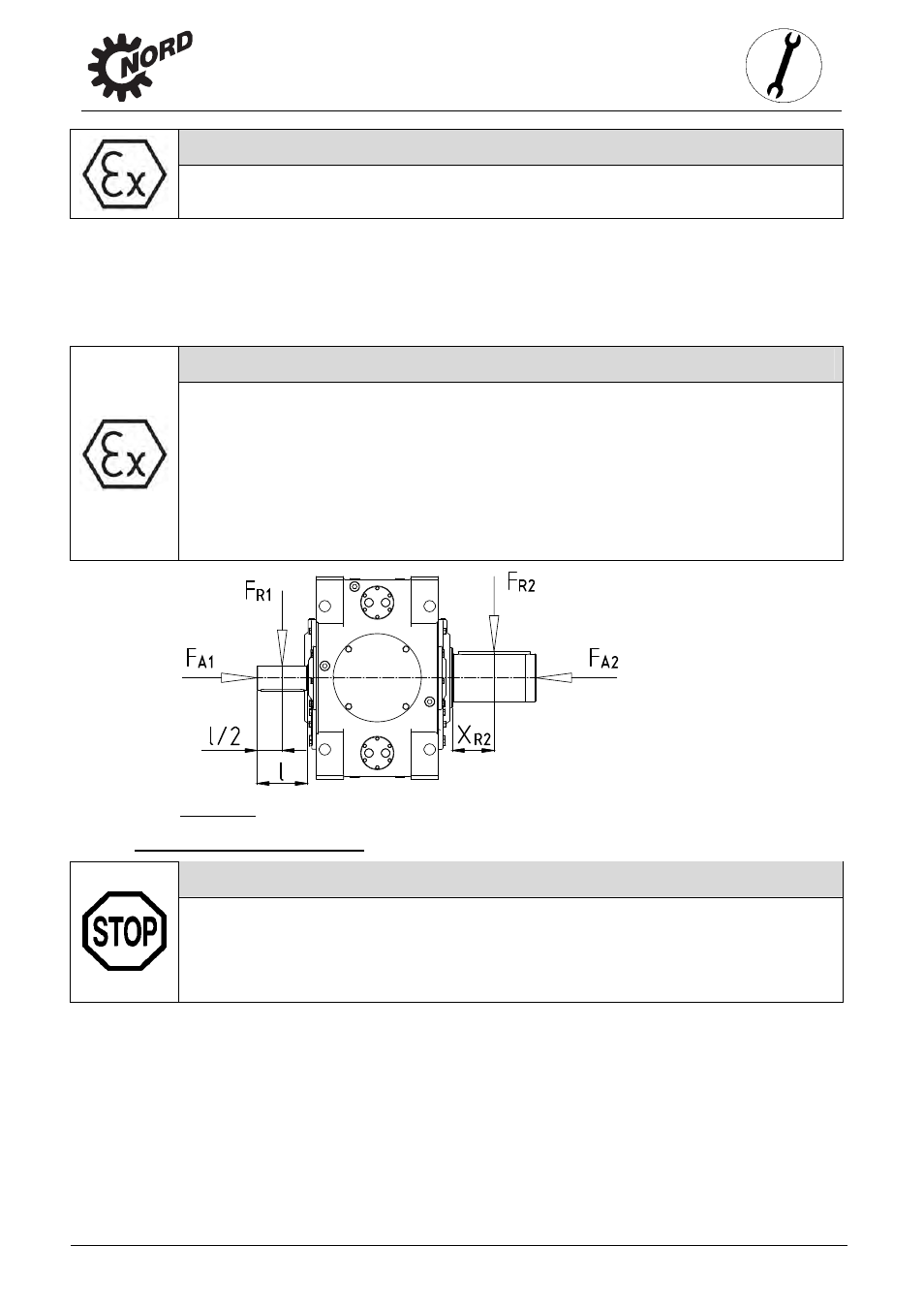

Drive and driven elements may apply to the gear unit only the maximum permitted radial

and lateral forces FR1 and FR2 and axial forces FA1 and FA2 indicated on the name plate

(see Section 3.4). Observe the correct tension, particularly on belts and chains. Additional loads

due to unbalanced hubs are not permitted.

Danger!

The radial force must be applied to the gear unit as closely as possible. For drive shafts

with free shaft ends the maximum permissible transverse force FR1 applies for the

application of the transverse force to the centre of the free shaft journal. For driven

shafts, the application of the transverse force FR2 must not exceed the dimension xR2.

If the transverse force FR2 for the driven shaft is stated on the name plate, but no

dimension xR2 is stated, the application of the force is assumed to be to the centre of

the shaft journal.

Figure 3-7: Permitted force applied to drive and driven shaft

3.10 Fitting push-on gear units

Attention!

The bearings, gear wheels, shafts and housing may be damaged by incorrect fitting.

The push-on gear unit must be fitted onto the shaft using a suitable puller, which will

not exert damaging axial forces on the gear unit. In particular, do not hit the gear unit

with a hammer.

Assembly and subsequent dismantling is facilitated by applying an anti-corrosive lubricant to the

shaft and the hub before fitting (e.g. Nord Anti-Corrosion Art.-No. 089 00099). Excess grease or

anti-corrosion agent may escape after assembly and may drip off. Clean these points on the

output shaft after a running-in time of approx. 24 hours. This escape of grease is not due to a

leak in the gear unit.