NORD Drivesystems B2050 User Manual

Page 19

3. Assembly instruction,

storage, transport, preparation, installation

www.nord.com B2050-GB-0613

-19-

When assembling push-on gears with torque supports, the support must not be distorted.

Distortion-free assembly is made easier if an elastic element (Option DG) is used.

3.11 Torque

support

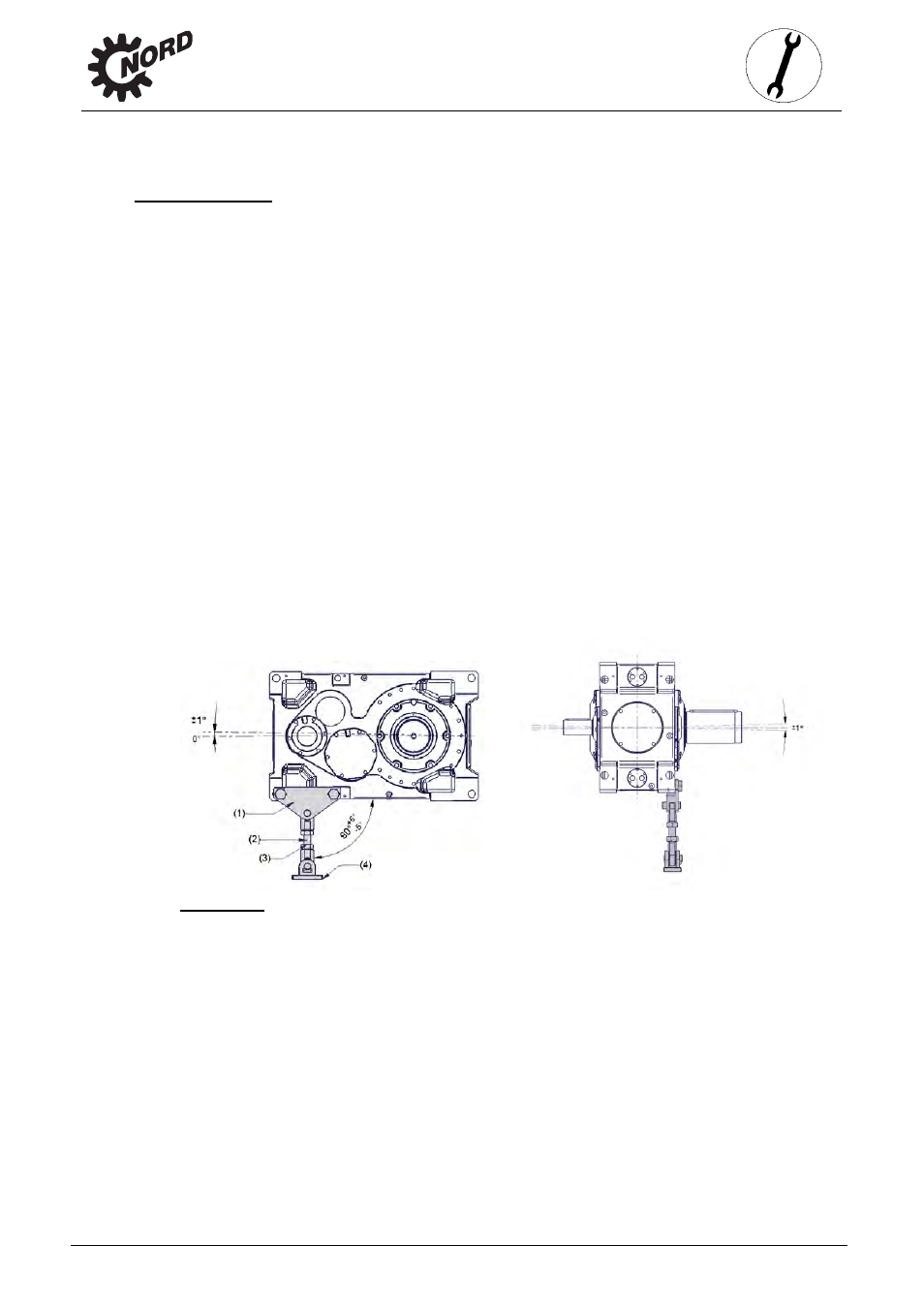

The length of the torque support can be adjusted within a certain range. The torque support

consists of a fork head with a bolt (1), a threaded bolt (2), a maintenance-free joint head (3) and

a fork plate with a bolt (4).

Assembly should be carried out from the side of the machine, in order to reduce the bending

moment on the machine shaft. Tension and pressure and installation upwards or downwards are

not permissible.

Distortion of the torque support during assembly or operation must be avoided, as otherwise the

service life of the output shaft bearings may be reduced. Torque supports are not suitable for the

transmission of radial forces, therefore they may only be used in combination with motor

adapters or couplings which cannot transmit radial forces.

For helical gear units with motor adapters, the torque support is located opposite to the motor

adapter.

The gear unit is aligned horizontally by means of the threaded bolt and the nuts of the torque

support and secured with lock-nuts.

Tighten the bolts on the torque support to the correct torque (see Section 6.4 for torque values)

and secure to prevent loosening. (e.g. Loctite 242, Loxeal 54-03)

Figure 3-12: Permissible installation deviations of the torque support