NORD Drivesystems B2050 User Manual

Page 20

3. Assembly instruction,

storage, transport, preparation, installation

-20- B2050-GB-0613

www.nord.com

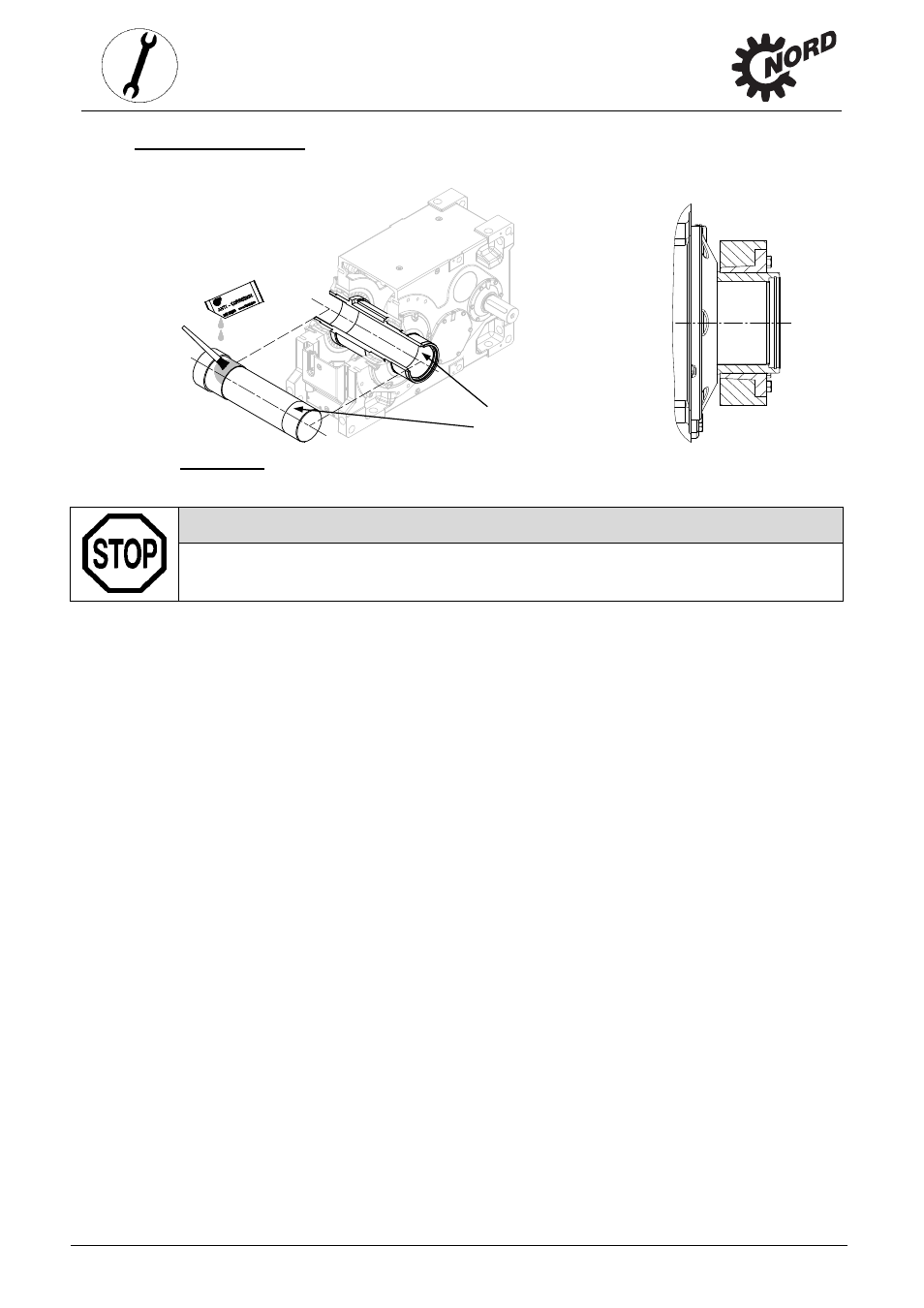

3.12 Fitting shrink discs

Figure 3-13: Mounting the solid shaft with a shrink disc

Attention!

Do not tighten the tensioning screws if the shaft is not inserted!

Assembly sequence:

1. Remove any transport securing devices.

2. Loosen but do not remove tightening bolt and tighten gently by hand until there is no play

between the outer ring and the inner ring.

3. Push the shrink disc up to the collar on the hollow shaft (see Fig. 3-13). The shrink disc is

easier to slide on if the bore of the inner ring is lightly greased.

4. Prior to mounting, grease the solid shaft only in the area which will later come into contact

with the bronze bush in the hollow shaft of the gear unit. Do not grease the bronze bush, in

order to prevent grease penetrating the area around the shrink connection.

5. The hollow shaft of the gear unit must be completely de-greased and c o m p l e t e l y

f r e e o f g r e a s e .

6. In the area of the shrink connection the solid shaft of the machine must be degreased and

c o m p l e t e l y f r e e o f g r e a s e .

7. Insert the solid shaft of the machine into the hollow shaft so as to completely fill the area

around the shrink connection.

8. Tighten the bolts successively in a clockwise direction by several turns – not crosswise –

with approx. ¼ rotation per turn.

9. After tightening the tensioning bolts the face of the inner ring on the screw side must be flush

with the face of the outer ring. The distortion of the shrink disc must be checked visually.

10. The hollow shaft of the gear unit and the solid shaft of the machine should be marked with a

line (felt-tip pen) in order to detect any slippage under load.

GREASE FREE!