Commissioning – NORD Drivesystems B2050 User Manual

Page 32

4. Commissioning

-32- B2050-GB-0613

www.nord.com

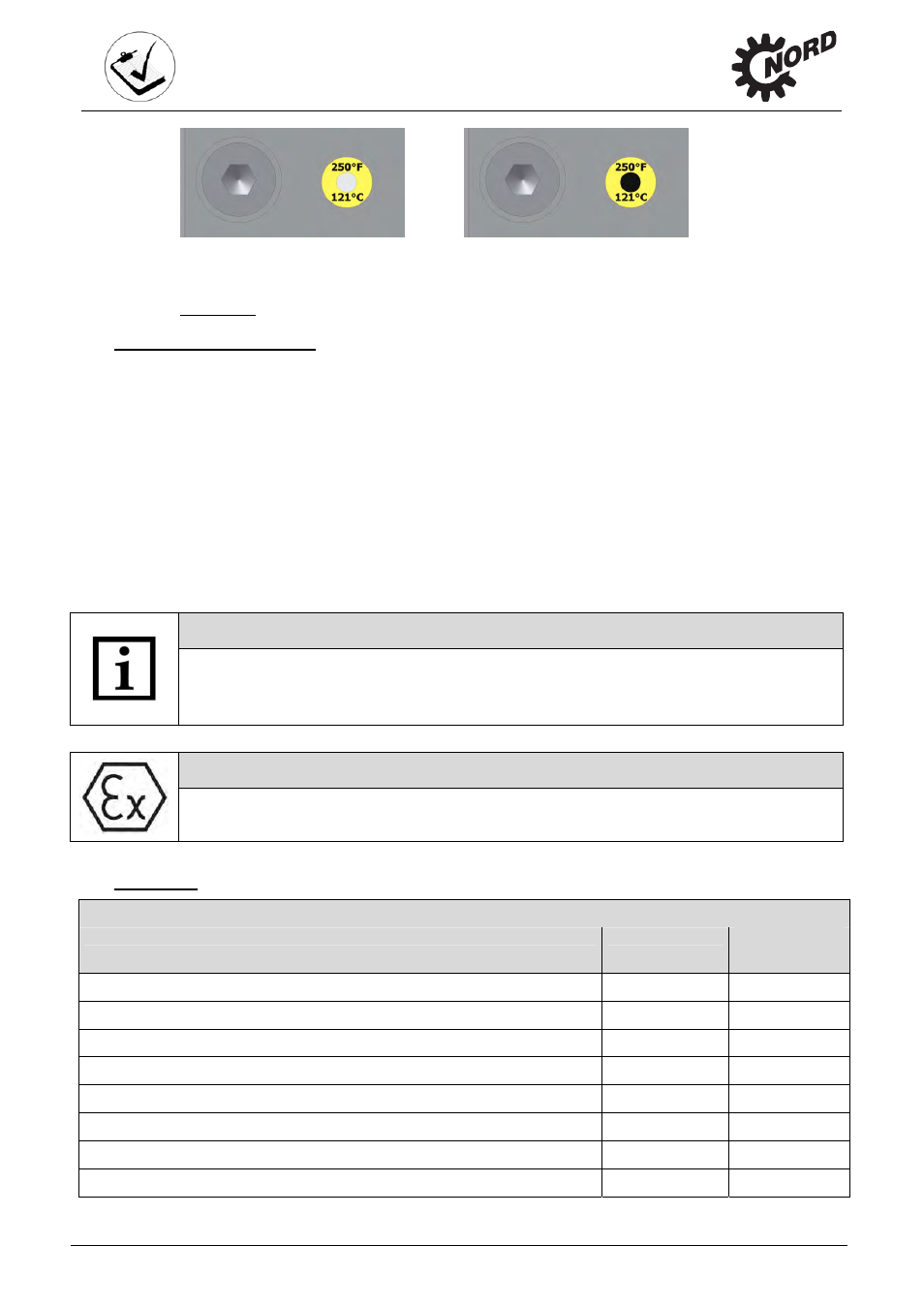

Centre dot is white:

Centre

dot

is

black:

OK

Temperature

was

too

high

Figure 4-3: Temperature sticker

4.7 Checking the gear unit

During a test run under full load, the gear unit should be checked for:

Unusual noises, such as grinding, knocking or rubbing noises

Unusual vibrations, oscillations or other movements

Production of steam or smoke

After the test run, the gear unit should be checked for:

Leaks

Slippage of the shrink disks. For this, the cover should be removed and a check carried out

whether the marking described in Section 3.12 shows a relative movement of the hollow shaft

of the gear unit and the machine shaft. Then the cover should be fitted as described in

Section 3.13.

Hinweis!

Shaft sealing rings are rubbing seals and have sealing lips made from an elastomer

material. These sealing lips are lubricated with a special grease at the factory. This

reduces the wear due to their function and ensures a long service life. An oil film in the

region of the rubbing sealing lip is therefore normal and is not due to leakage.

Danger!

The drive must be shut down and Getriebebau Nord consulted if any irregularities are

observed during the checks described above.

4.8 Checklist

Checklist

Objective

Checked on:

Information –

see Section

Is any transportation damage or damage apparent?

Sec. 3.3

Does the labelling on the name plate conform to the specifications?

Sec. 6.1

Does the required configuration conform with the actual installation?

Sec. 3.5

Is the pressure vent screwed in?

Sec. 3.7

Do all drive and driven elements have ATEX approval?

Sec. 3.7

Are the external gear shaft forces within permitted limits (chain tension)?

Sec. 3.9

Is the torque support correctly fitted?

Sec. 3.11

Are contact guards fitted to rotating components?

Sec. 3.13