Appendix – NORD Drivesystems B2000 User Manual

Page 55

6. Appendix

www.nord.com B2000-GB-0413

-55-

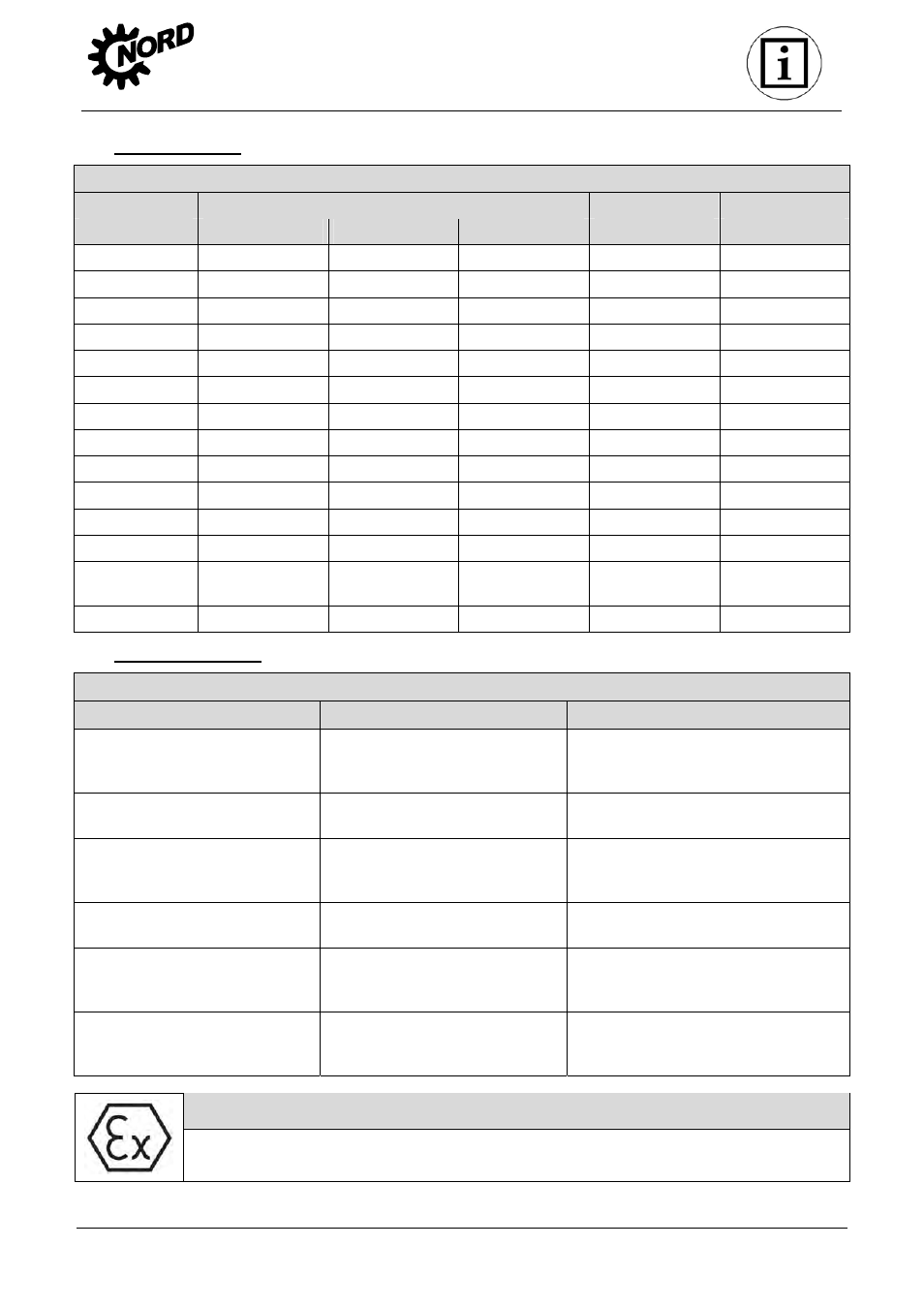

6.3 Torque values

Bolt Torques [Nm]

Size

Screw connections in the strength classes

Sealing

Threaded pin

8.8

10.9

12.9

screws

on coupling

M4 3.2 5

6

-

-

M5 6.4 9 11 -

2

M6 11 16 19 -

-

M8 27 39 46 11 10

M10

53 78 91 11 17

M12 92 135 155 27 40

M16 230 335 390 -

-

M20 460 660 770 -

-

M24 790 1150 1300 80

-

M30 1600 2250 2650 170

-

M36 2780 3910 4710

-

-

M42 4470 6290 7540

-

-

Angled pipe, as

in Figure 4-1

- - - 12 -

G1¼

-

-

-

20

-

6.4 Troubleshooting

Gear unit malfunctions

Fault

Possible cause

Remedy

Unusual running noises,

vibrations

Oil too low or

bearing damage or

toothed wheel damage

Consult NORD Service

Oil escaping from gear unit or

motor

Defective seal

Consult NORD Service

Oil escaping from

pressure vent

Incorrect oil level or incorrect,

contaminated oil or unfavourable

operating conditions

Oil change

Use oil expansion tank (Option OA)

Gear unit becomes too hot

Unfavourable installation

conditions or gear unit damage

Consult NORD Service

Shock when switched on,

vibrations

Defective motor coupling or

loose gear unit mounting or

defective rubber element

Replace elastomer gear rim, tighten

motor and gear unit fastening bolts,

replace rubber element

Drive shaft does not rotate

although motor is running

Fracture in gear unit or

defective motor coupling or

shrink disc slippage

Consult NORD Service

Danger!

Warning: shut down the gear unit immediately if any faults occur!