Storage, preparation, installation – NORD Drivesystems B2000 User Manual

Page 14

3. Storage, preparation,

installation

-14-

B2000-GB-0413

www.nord.com

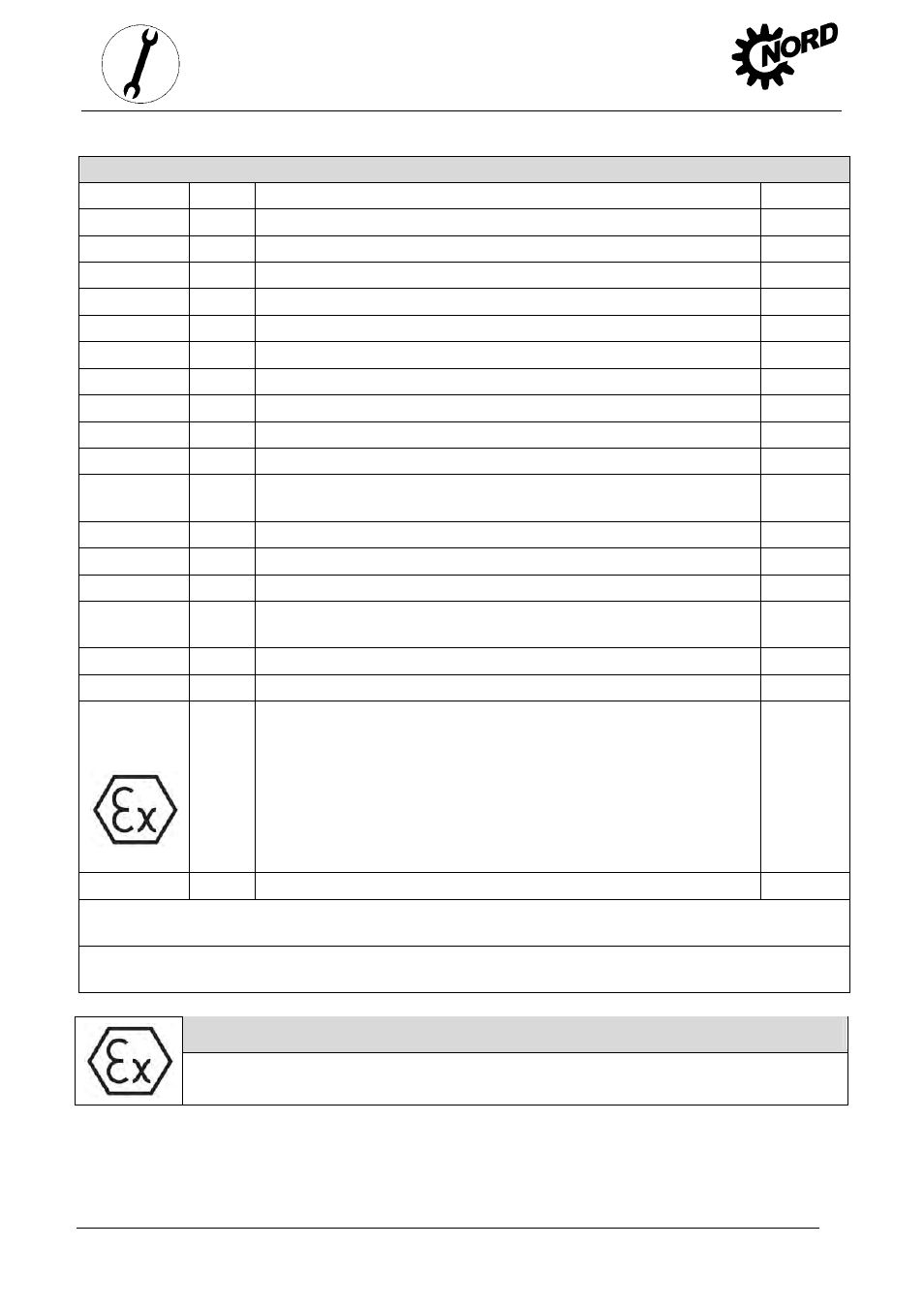

Explanation of the Rating Plate

Abbreviation Unit

Designation

See

Typ

-

NORD gear unit type

No. -

Serial

number

iges

-

Overall gear unit ratio

n2 min-1

Rated speed of gear unit drive shaft*

n1 min-1

Rated speed of the gear unit drive shaft or the drive motor*

IM

-

Configuration (installation orientation)

Section 6.1

M2

Nm

Max. permissible gear unit drive shaft torque

P1

kW

Max. permissible drive power or motor power

Bj

-

Year of manufacture

FR2

kN

Max. permissible transverse force on the gear unit driven shaft

Section 3.8

FR1

kN

Max. permissible transverse force on the gear unit drive shaft for option

W

Section 3.8

Tu

°C

Permissible ambient temperature for the gear unit

FA2

kN

Max. permissible axial force on the gear unit driven shaft

Section 3.8

FA1

kN

Max. permissible axial force on the gear unit drive shaft for option W

Section 3.8

MI

h

Interval between general overhauls of the gear unit in operating hours

or details of the non-dimensional maintenance class CM

Section 5.2

Section 5.2

xR2

mm

Max. dimension for the point of application of the transverse force FR2 Section 3.8

Oil

-

Gear unit oil type (standard designation)

Section 6.2

Last line

-

Labelling as per ATEX (DIN EN 13463-1):

1. Group (always II, not for mines)

2. Category (2G, 3G for gas or 2D, 3D for dust)

3. Ignition protection type if fitted (c)

4. Explosion group if applicable (IIC, IIB)

5. Temperature class (T1-T3 or T4 for gas) or max. surface

temperature e.g. 125°C for dust)

6.

Temperature measurement on commissioning (X)

Section 4.3

S

-

Number of the special documentation, consisting of serial no. / year

*The maximum permissible speeds are 10% above the rated speed, if the maximum permissible drive power

P1 is not exceeded.

If the fields FR1, FR2, FA1 und FA2 are empty, the forces are zero. If the field xR2 is empty, the point of

application of force FR2 is central on the drive shaft journal (See Figure 3-4).

It should be noted that with geared motors, the electric motor has its own rating plate with a

separate ATEX labelling. The motor labelling must also comply with data for the planning of the

plant or the machine. The lowest explosion protection of the gear unit and the motor

Danger!

It must be checked and ensured that the gear unit type, all technical data and the ATEX

labelling conform to the planning of the plant or the machine.