Storage, preparation, installation – NORD Drivesystems B2000 User Manual

Page 19

3. Storage, preparation,

installation

www.nord.com B2000-GB-0413

-19-

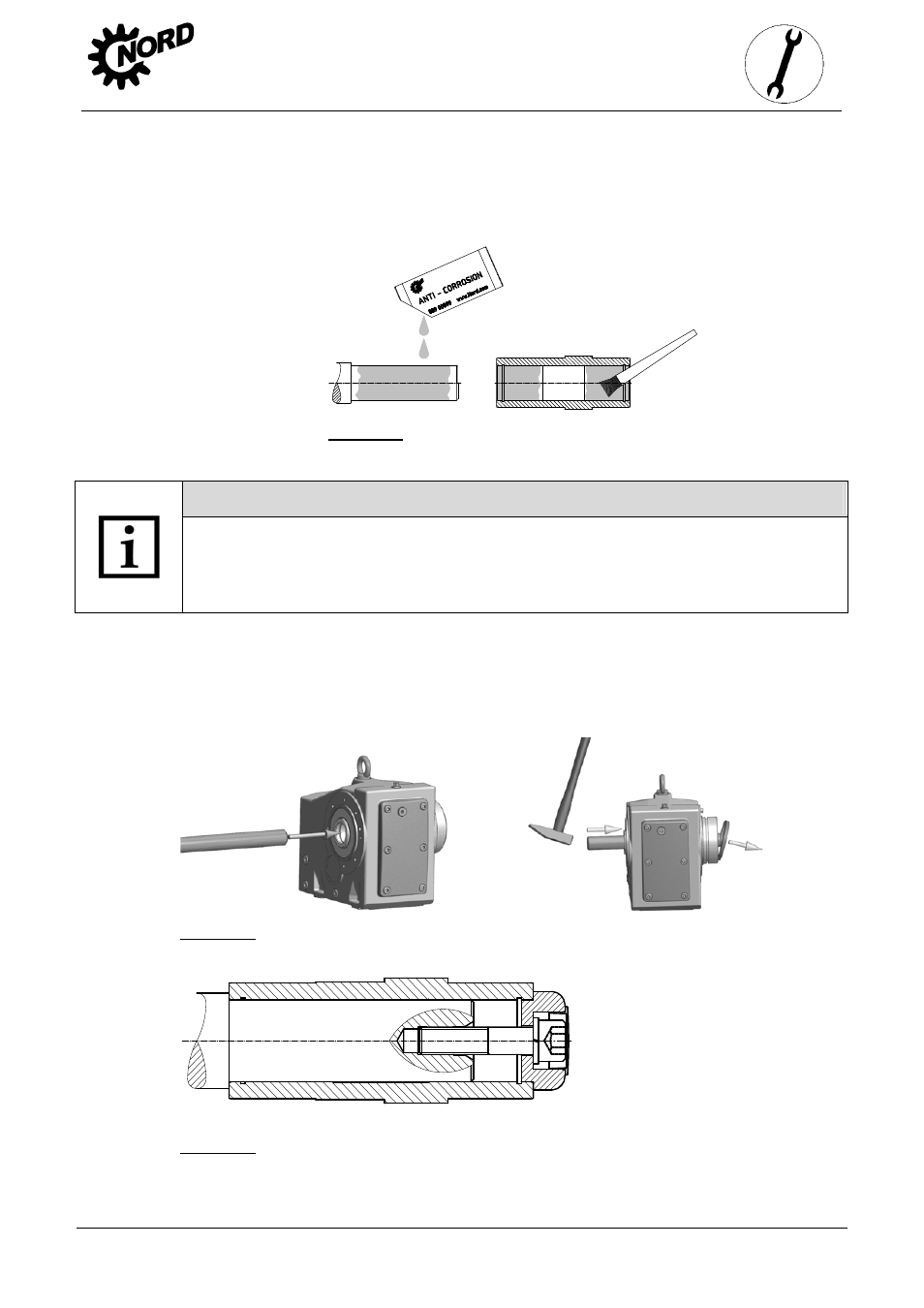

Assembly and subsequent dismantling is facilitated by applying an anti-corrosive lubricant to the

shaft before fitting (e.g. Nord Anti-Corrosion Art.-No. 089 00099). Excess grease or anti-

corrosion agent may escape after assembly and bay drip off. Clean these points on the output

shaft after a running-in time of approx. 24 hours. This escape of grease is not due to a leak in

the gear unit.

Figure 3-5: Applying lubricant to the shaft and the hub

For shaft mounted gear units with option H66 and fastening element (Option B) the pressed-in

closing cap must be pushed out before fitting the gear unit. The pressed-in closing cap may be

destroyed during dismantling. As standard a second closing cap is supplied as a loose spare

part. After fitting the gear unit, fit the new / new condition closing cap as described in Section 3.11.

Figure 3-6: Removing the factory-fitted closing cap

Figure 3-7: Gear unit mounted to shaft with a shoulder using the fastening element

Note!

The gear unit can be fitted to shafts with and without a shoulder using the fastening

element (Option B). Tighten the bolt of the fastening element to the correct torque. (See

Chapter 6.3 for torque values.) For gear units with option H66, the factory-fitted closing

cap must be removed before fitting.