Storage, preparation, installation – NORD Drivesystems B2000 User Manual

Page 25

3. Storage, preparation,

installation

www.nord.com B2000-GB-0413

-25-

3.13 Subsequent paintwork

Attention!

For retrospective painting of the gear unit, the radial seals, rubber elements, pressure venting

valves, hoses, type plates, adhesive labels and motor coupling components must not come

into contact with paints, lacquers or solvents, as otherwise components may be damaged or

made illegible.

3.14 Temperature sticker

The temperature class or the maximum surface temperature can be seen from the ATEX

labelling in the last line of the rating plate.

Examples: II 2G c IIC T4 X or II 3D 125°C X

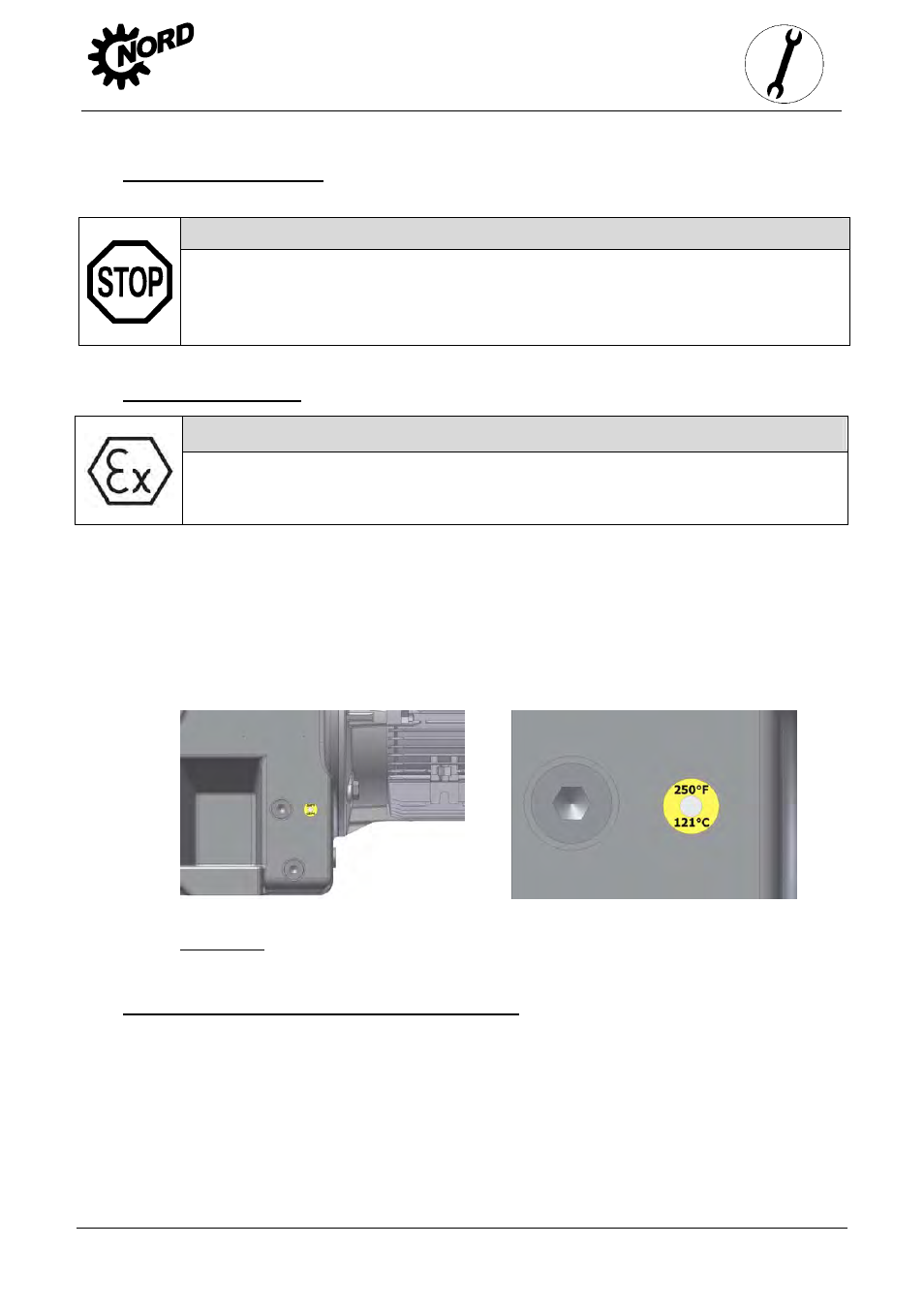

The temperature sticker must be affixed next to the oil level screw (See Section 6.1) towards the

motor. For gear units with an oil level vessel, the temperature sticker must be affixed in the same

position as for gear units without an oil level vessel. For gear units which are lubricated for life,

without oil maintenance, the temperature sticker should be affixed next to the rating plate.

Figure 3-15: Position of the temperature sticker

3.15 Fitting the cooling coil to the cooling system

The cooling coil is recessed into the housing cover (See Item 2, Figure 3-16). Cutting ring screw

threads (see Item 1, Figs. 3-16) are located at the casing cover for the connection of a pipe with

an external diameter of 10 mm according to DIN 2353. Remove the drain plug from the screw

neck prior to assembly to avoid any contamination of the cooling system. The screw necks

should be connected with the coolant circuit, which must be provided by the operator. The flow

direction of the coolant is irrelevant.

Danger!

With temperature class T4 gear units with a maximum surface temperature of less than

135°C the supplied self-adhesive temperature sticker (printed with value 121°C) must

be affixed to the gear unit housing. (Part No.:283 9050).