Service and maintenance – NORD Drivesystems B2000 User Manual

Page 36

5. Service and maintenance

-36-

B2000-GB-0413

www.nord.com

New

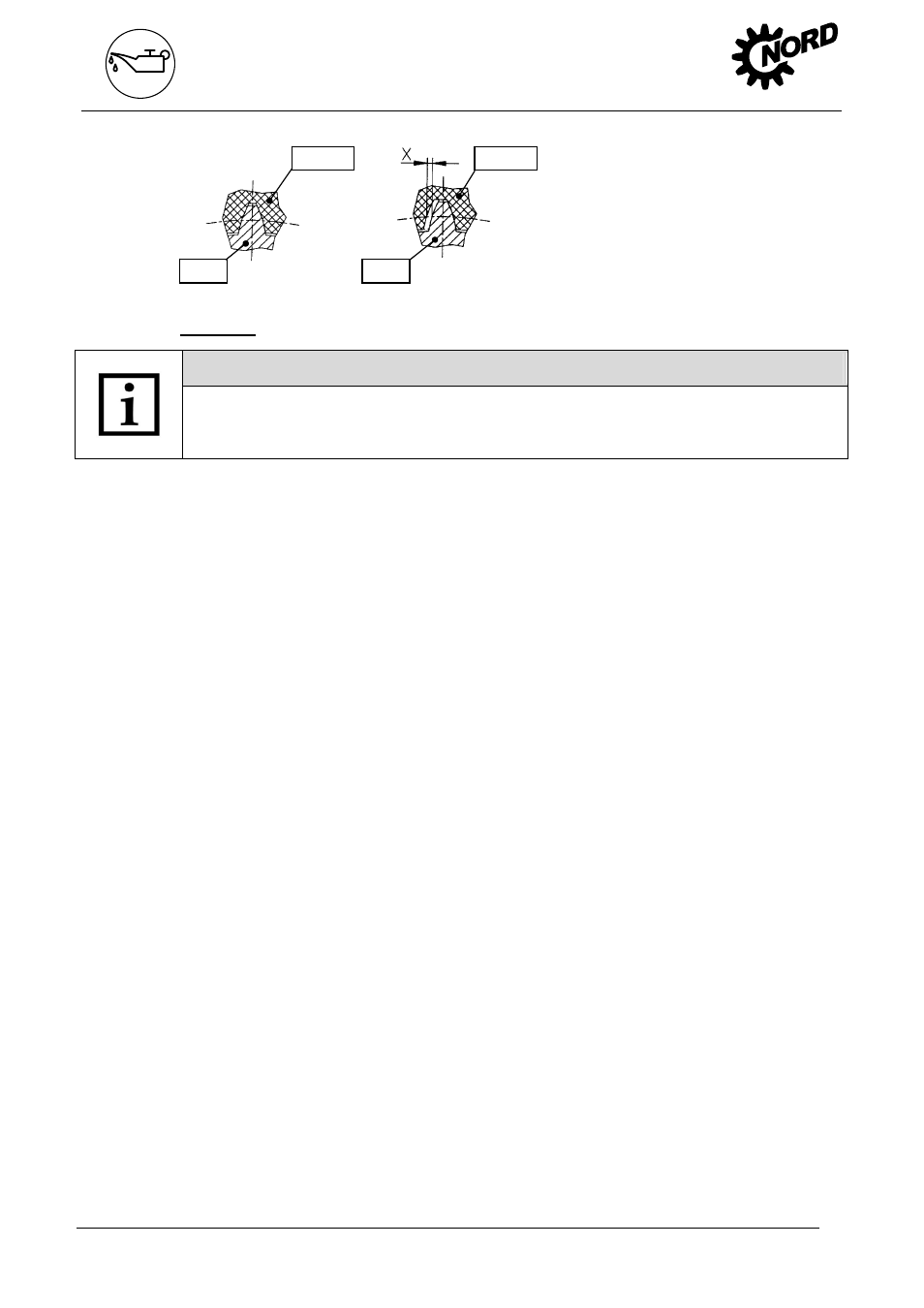

Wear limit X = 0.8mm

Figure 5-2: Measurement of gear sleeve wear for gear BoWex

couplings

Regreasing

Some gear unit designs (free drive shaft, Option W, agitator designs VLII and VLIII) are

equipped with a regreasing device.

For agitator versions VLII and VLIII, the vent screw located opposite to the grease nipple must

be unscrewed before regreasing. Grease should be injected until a quantity of 20-25g escapes

from the vent hole. After this, the vent plug must be reinserted and tightened.

For Option W and some IEC adapters, the outer roller bearing must be regreased with approx.

20-25g of grease via the grease nipple provided

Recommended grease: Petamo GHY 133N (see Section 6.4: Klüber Lubrication).

Cleaning or replacing the vent screw

Unscrew the pressure vent, thoroughly clean the vent screw (e.g. with compressed air) carry out

a function test and fit the vent screw in the same place. If necessary, use a new vent screw.

Replacing the automatic lubricant dispenser

Screw-off the cartridge case cover (2), (see Figure 4-2). The lubrication dispenser (5) is screwed

out and replaced with a new component (Part No. 283 0100). Then activate (see Chapter 4.2)!

Changing the oil

The figures in Section 6.1 show the oil drain screw, the oil level screw and the pressure vent

screw for various designs. Sequence:

1. Place the drip tray below the oil drain screw

2. Completely remove oil level screw, screwed sealing plug with dipstick if an oil level tank is

being used and oil drain screw.

Note!

If the examination only shows slight wear (25% of the limiting value), it is permissible to

extend the interval for examination of the coupling to twice the normal period, i.e. 5000

operating hours and at least every year.

Hub

Hub

Sleeve

Sleeve