Dwyer TFM-LP User Manual

Page 8

F-20-TF-L, pg. 8 of 30

CAUTION:

DO NOT over tighten the fittings into the sensor

body. Excessive force may damage the sensor body and will

NOT be repaired under warranty.

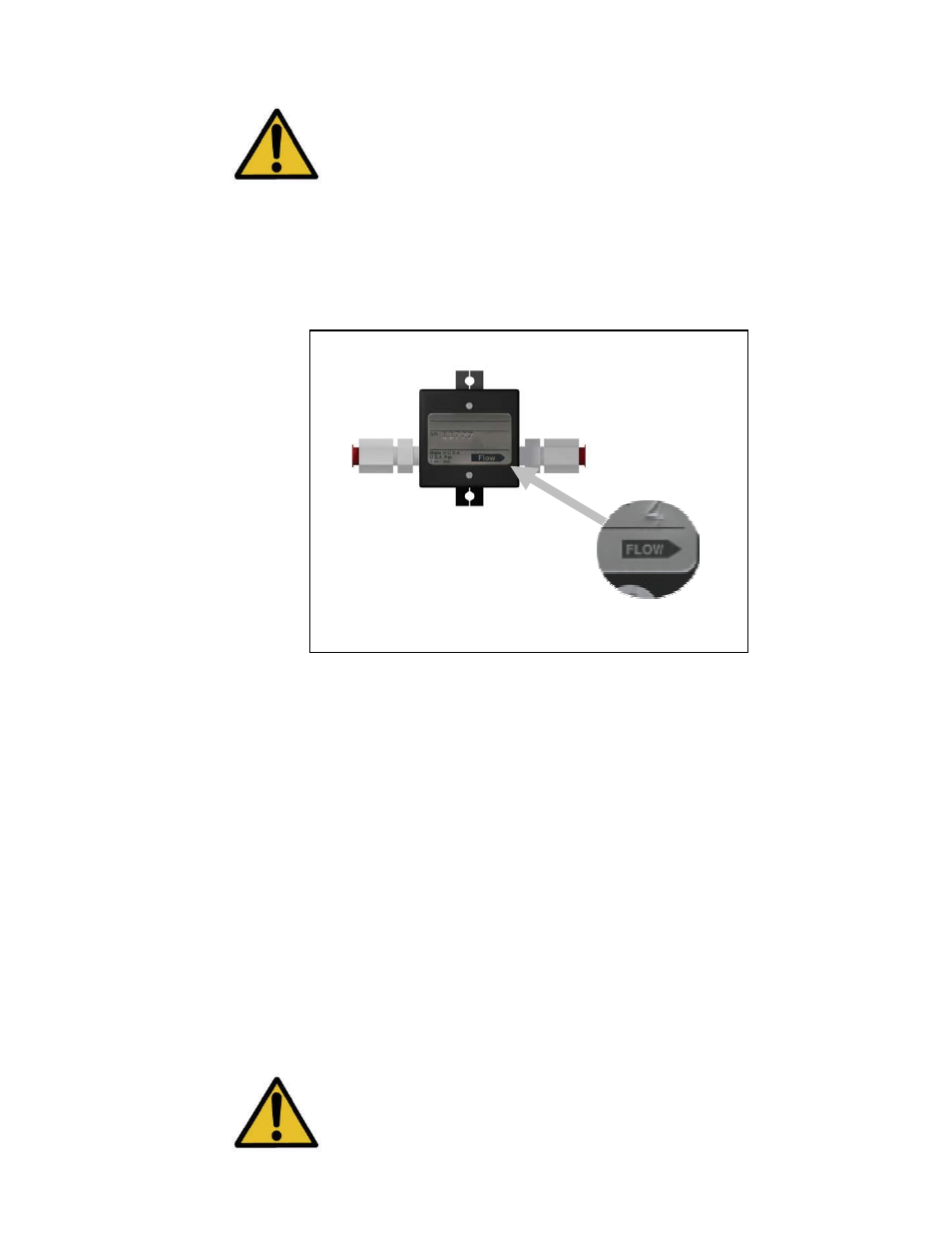

The flow direction for the unit is clearly marked on the label. Do not reverse

the flow direction or the unit will not function.

Close Up of Label Showing Flow Directions

(All models similar)

For the best results, precautions should be taken to minimize the amount of

turbulence in the flow stream. Avoid valves, fittings, curves in the tube, and

changes in the internal diameter or any other restrictions close to the inlet of

the sensor. The tubing ID should be as large as possible and preferably not

smaller than the ID of the fittings installed on the sensor.

For 0.2-2.0 L/min units a 10 cm straight length of tube before the sensor is

recommended. For higher flow range units (0.5-5.0 L/min and 1.0-10.0

L/min), a 20 cm straight length of tubing before the sensor is recommended.

If this is not possible it is recommended that straight lengths between all

connections on the inlet side of the sensor are as long as possible and 90

degree fittings (with a large enough ID) are used instead of curves in the

tubing.

4.

Electrical Connections

CAUTION:

Incorrect wiring may cause severe damage to the

unit. Applying an AC voltage (115VAC or 230VAC) directly to

the unit will cause damage. Read the following instructions

carefully before making any connections.