Dwyer TFM-LP User Manual

Page 29

F-20-TF-L, pg. 29 of 30

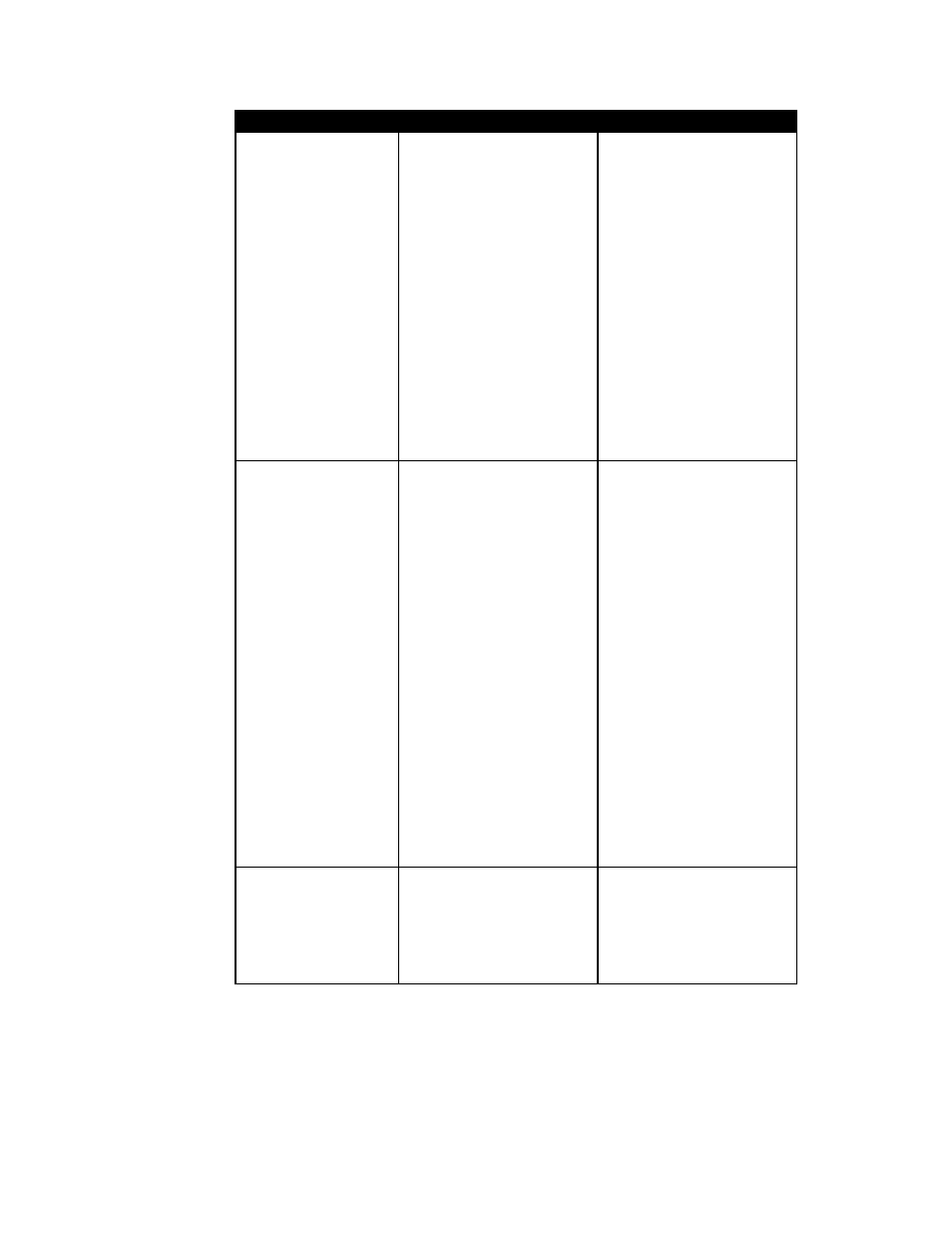

Symptom

Possible Cause

Method of Correction

Flow indication is not

linear and output too

low at lower flows

Attempting to measure flows

below the specified

minimum for the unit

Liquid is too viscous

Entrapped air or gas

Mechanical sensor

assembly damaged

Use higher flow rates.

Best results are obtained

with liquids that have a

viscosity of 10cS or less.

Contact Dwyer Customer

Service for further

information.

Remove entrapped air (see

section C2).

Unit must be returned for

repair (see Section D3).

Flow indication

“bounces” or

fluctuates

Flow is actually fluctuating

Not using the fittings

supplied by the

manuafacturer

Entrapped air or gas

Turbulence in tubing or

sensor

Fluctuating input power

Mechanical sensor

assembly damaged

Correct flow source to

obtain steady flow.

Use the supplied fittings.

Remove entrapped air (see

section C2).

Straighten the inlet tubing or

lengthen it to at least 6”

(150mm) (see section B3).

Correct the power source or

change to a regulated

supply.

Unit must be returned for

repair (see Section D3).

Flow indication is

fixed at one value

The maximum rated flow for

the unit is being exceeded.

Output circuits may be

damaged

Reduce the flow.

Unit must be returned for

repair (see Section D3).