H. troubleshooting guide – Dwyer TFM-LP User Manual

Page 28

F-20-TF-L, pg. 28 of 30

H.

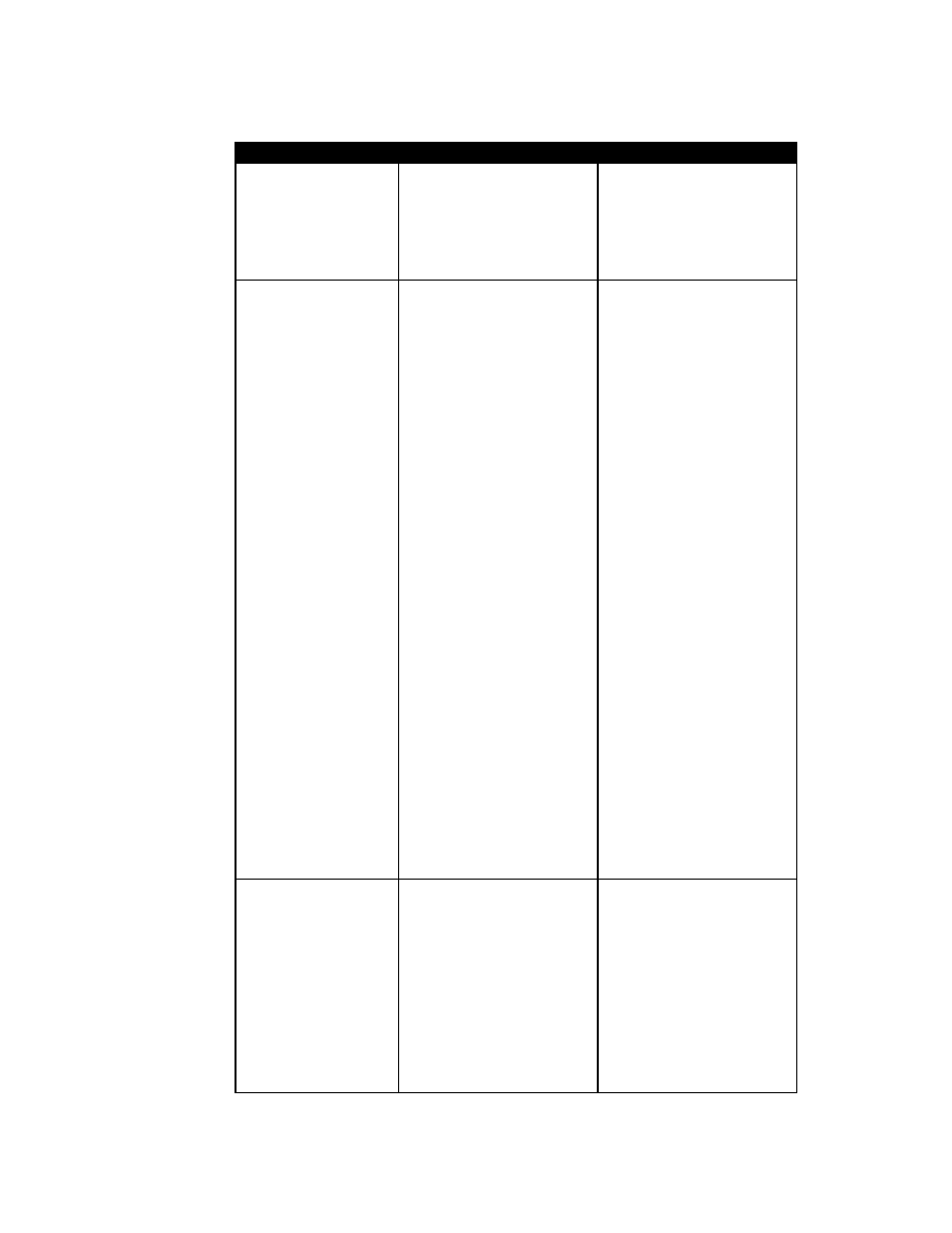

Troubleshooting Guide

Symptom

Possible Cause

Method of Correction

Unit Leaks.

Fittings not tight enough.

Sensor assembly cracked.

Tighten fittings (see section

B3).

Unit must be returned for

repair (see Section D3).

No output signal or

flow indication.

No power or low power.

No flow passing through

unit.

Output shorted or

overloaded.

Improper connection.

Moisture on internal

electronics.

Output circuitry damaged.

Liquid not translucent

enough.

Attempting to measure flows

below the specified

minimum for the unit.

Apply correct power.

Display or output should

read zero if there is no flow.

Increase the flow rate until a

reading is obtained. (Do not

exceed the specified

maximum flow!).

Check electrical connections

(see section B4).

Check electrical connections

(see section B4) and ensure

connector is correctly

plugged in.

Allow unit to dry out in a

dry environment.

Unit must be returned for

repair (see Section D3).

Contact Dwyer Customer

Service for assistance.

Use higher flow rates.

Flow reading

accuracy is outside

the specification.

Liquid has a different

viscosity and / or specific

gravity than water at 20°C.

Entrapped air or gas.

Mechanical sensor

assembly damaged.

Calculate the flow reading

error / offset as explained

in section C6/C7.

Remove the entrapped air

(see section C2).

Unit must be returned for

repair (see Section D3).