Optimiser – Caleffi 1522 User Manual

Page 7

7

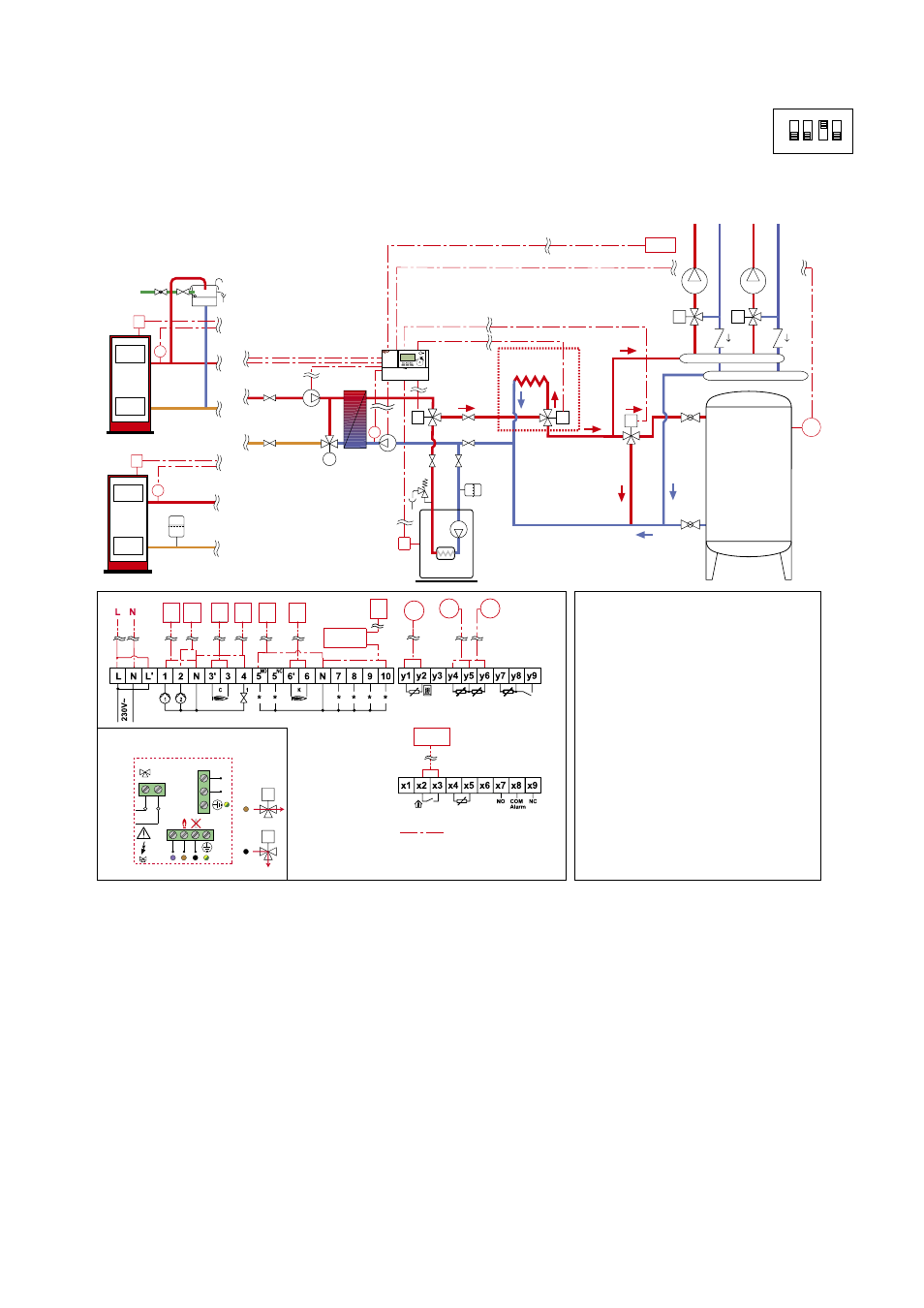

Hydraulic diagrams of programs

Operating principle

The 1522 series regulator automatically manages a system composed of a solid fuel generator, integration gas boiler and inertial water storage

in parallel on the heating system.

On the request of room thermostat RT (not supplied in the pack), the regulator activates the solid fuel generator with priority using contact K

(for generators that can be activated electrically). When the minimum working temperature of the solid fuel generator has been reached (as

detected by probe S1), the regulator starts pump P1, diverts valve V1 to connect the heat exchanger to the system and starts pump P2. With

the solid fuel generator off or not yet at working temperature, the regulator starts the integration boiler by means of contact C, stopping pumps

P1 and P2 and diverting diverter valve V1 to the boiler.

In the case of solid fuel generator overtemperature, the regulator sends the flow rate of the secondary circuit either to the system (in the

presence of room thermostat demand) or to an optional dissipation system, if present.

The inertial water storage in parallel is managed in accordance with the logic described on page 6. By means of diverter valve V5 (not supplied

in the pack, e.g.: Caleffi 6443..3BY series + relay box code F29525) the regulator manages all phases of loading and unloading of the water

storage, which is kept closed only if the gas boiler has been activated. Connection of the parallel water storage to the rest of the system is

managed by the regulator by comparing the temperature readings of probes S1 (located on the solid fuel generator flow pipe), S5 (located on

the heat exchanger return line) and S4 (located on the parallel water storage). For probe S5 it is advisable to use the following working

set-points: 45°C for radiator systems, 30°C for radiant panel systems. The gas boiler starts when the solid fuel generator temperature is below

the minimum working temperature TSG (measured by probe S1) and the heat exchanger return temperature TR (measured by probe S5) is 5°C

below the value set on the regulator (TR set, fixed hysteresis value 5K).

Program 4 (software code PR83): BASIC FACTORY PROGRAM

Heating + management of inertial water storage in parallel on the heating system

Number of probes utilised: 3

Probe S1 located on solid fuel generator flow

Probe S5 located on heat exchanger inlet on secondary side of circuit

Probe S4 located on the inertial water storage in parallel on the heating system

ON

1 2 3 4

V5

M

M

S5

D

D

T

P1

P2

C

V1

RT

D

K

S1

K

S1

S4

V4

V5

S5

S4

F29525

K

V4

C

P1 P2

C

V1

S1

RT

-

+

Optimiser

Regulator 152200

V5=Zone valve 6443..3BY

Com.

Relè 1 VA

8 VA

L

N

N

10

Heating system

HEATING

BOILER

Optional

dissipator

Closed vessel

Open vessel

wiring to be made

Wiring diagram

L Live

N Neutral

L’

1

Live jumper

2 ON pump P2

ON pump P1

3’ Gas generator C

3

Gas generator C

N

Neutral common

4

ON diverter valve V1

5

NO

ON diverter valve V4

to optional dissipator

5

NC

6’ Solid fuel generator K

10 ON valve V5 to load the

parallel water storage

N

Neutral common

6’ Solid fuel generator K

y1 Probe S1

y2 Probe S1

y4 Probe S5

y5 Probe S5 and S4

common

y6 Probe S4

x2 Room thermostat

RT contact

x3 Room thermostat

RT contact

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

INERTIAL

WATER

STORAGE

IN PARALLEL

Wiring diagram of F29525

relay box - 230 V ˜ 50 Hz

V5

D

V5

D