Meter installation, Meter operation – Badger Meter Model IOG User Manual

Page 7

METER INSTALLATION

READ THE FOLLOWING INFORMATION AND HAVE A THOROUGH UNDERSTANDING BEFORE PROCEEDING WITH METER

INSTALLATION ONLY QUALIFIED PERSONNEL SHOULD PERFORM METER INSTALLATION

•

Install a type 60 mesh strainer or Y or basket as close to the inlet side of the meter as possible Strainers prevent dirt

and other fluid contaminants from impeding meter performance Strainers require periodic cleaning, as clogged

strainers also impede meter performance Contact your local representative for specific information, per your

specific application

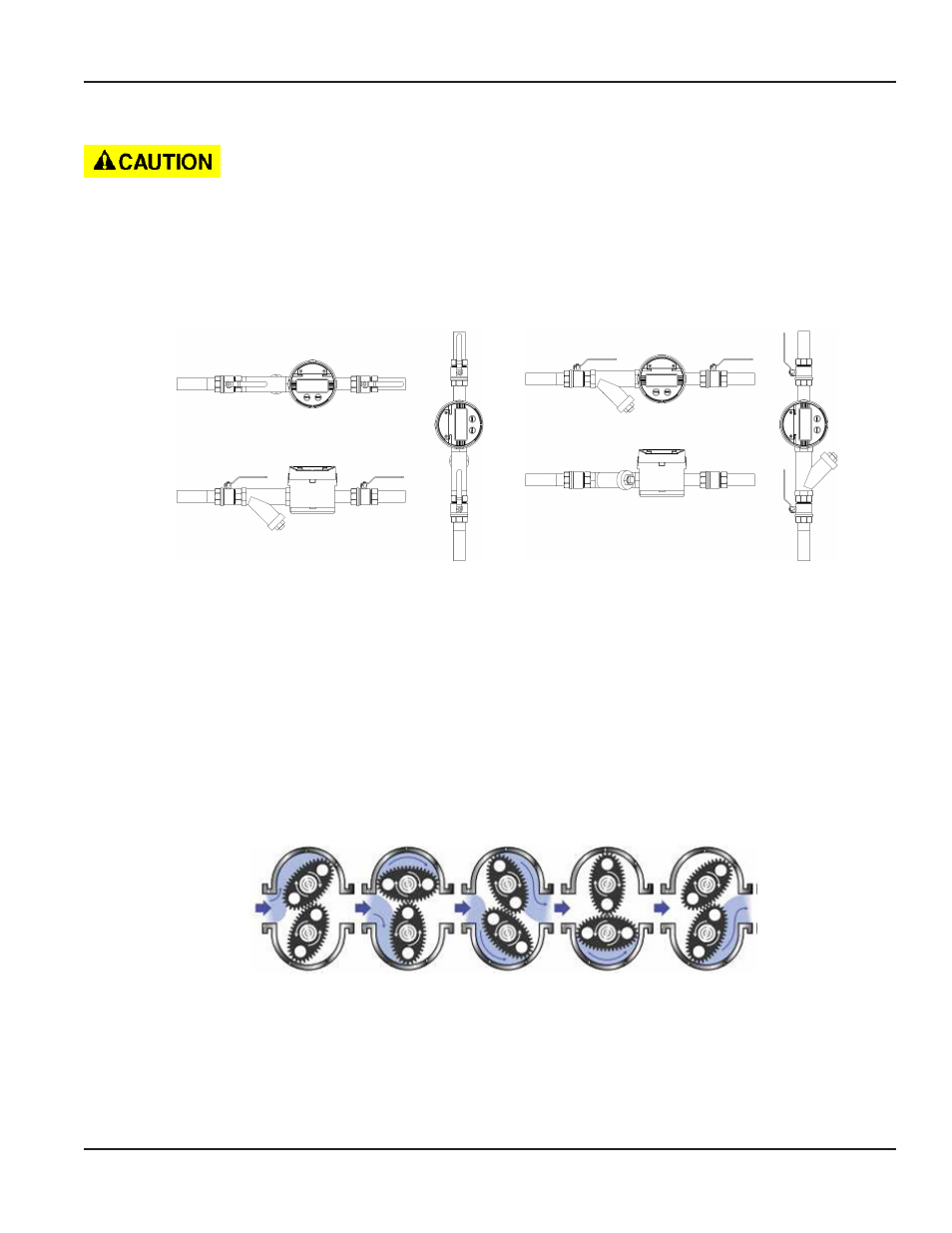

Figure 1E: Meter Installation

•

Turn off any associated pumps to reduce line pressure and slowly fill the line and meter with fluid before restarting

pumps Doing so reduces the possibility of meter damage caused by errant air pressures in the line and meter

•

Make sure all pipe conforms to the same pressure output rating as the pump

•

Make sure to apply thread sealant to all pipe threads

•

Install the meter along the meter shafts in a horizontal plane (see Figure 1)

•

Check for and repair leaks upon initialization of fluid flow

METER OPERATION

Figure 2E: Operation Depiction

Fluid enters the inlet port and then passes through the metering chamber Inside the chamber, fluid forces the internal gears

to rotate before exiting through the outlet port Each rotation of the gears displaces a specific volume of fluid As the gears

rotate, a magnet on each end of the gear pass a reed switch in the top-mounted register's circuit board The reed switches

send pulses to the microprocessor in the register to change the LED display segments

Upon initialization and continuation of fluids through the line and meter, the expected pressures per flow are:

Strainer

Strainer

User Manual

Page 7

May 2013