Safety of the installation, Pressure switch, Flame probe – A.O. Smith 30 User Manual

Page 17

Instruction manual SGS

17

gis

2.4.5

Fan

The fan (18) provides an optimum air supply when there is a heat demand. As

a safety feature, the fan ensures that any gases present in the combustion

chamber are removed, both before and after combustion. We refer to this as

pre- and post-purge.

The fan speed is continuously monitored by the electronic controller (4). The

electronic controller takes control if the speed of rotation varies too much from

the set value.

2.4.6

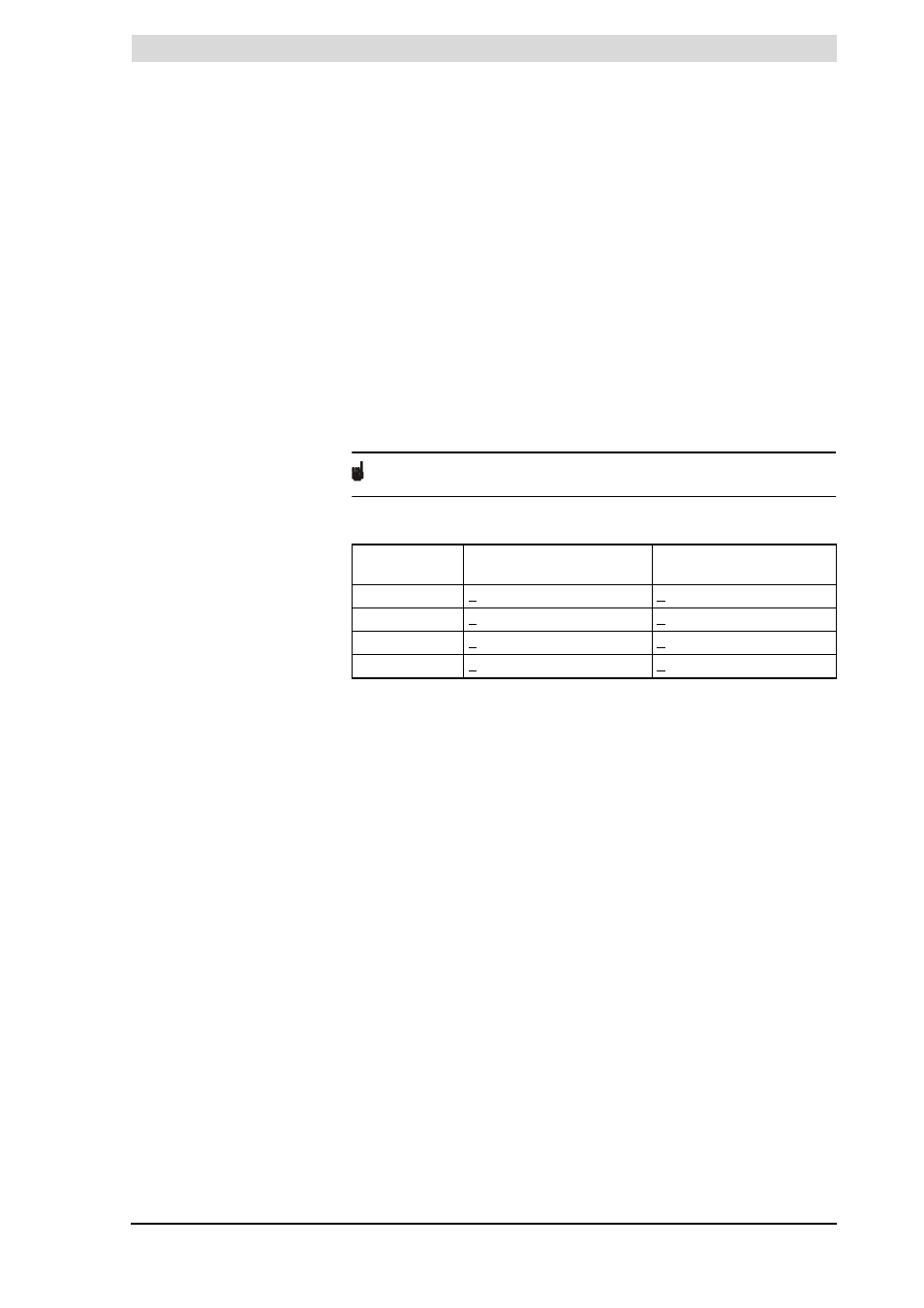

Pressure switch

The pressure switch ensures the discharge of flue gases and the supply of

incoming air during the pre-purge and normal running of the appliance. The

default state of the pressure switch is open. When sufficient pressure difference

is reached, the pressure switch closes. However, in the event of a fault, the

pressure switch is tripped open, and the heating cycle is interrupted. The table

shows the trip point per appliance.

Note

The trip point of the pressure switch is not adjustable.

Pressure switch trip points

2.4.7

Flame probe

To ensure that no gas can flow when there is no combustion, the water heater

is fitted with a flame probe (21). The electronic controller uses this probe to

detect the presence of a flame, by means of ionisation detection. The electronic

controller closes the gas control the instant it detects that there is a gas flow but

no flame.

2.5

Safety of the

installation

In addition to the appliance's standard built-in safety monitoring, the appliance

must also be protected by an expansion vessel, expansion valve, pressure

reducing valve, non-return valve and a T&P valve.

The use of an expansion vessel, expansion valve and/or pressure reducing

valve depends on the type of installation: unvented or vented.

2.5.1

Unvented installation

With an unvented installation, an expansion valve valve and expansion vessel

prevent the buildup of excessive pressure in the tank. This prevents damage

being caused to the enamelled coating (in the appliance) or to the tank. A non-

return valve prevents excessive pressure buildup in the water supply system.

This valve also prevents water from flowing backwards from the tank into the

cold water supply system. The pressure reducing valve protects the installation

against an excessively high water supply pressure (> 8 bar). These components

are fitted to the cold water pipe

(3.6 "Water connections, Vented")

.

Appliance

Closing pressure

difference

Opening pressure

difference

SGS 28

> 635 Pa

< 605 Pa

SGS 30

> 855 Pa

< 825 Pa

SGS 50

> 885 Pa

< 855 Pa

SGS 60

> 1085 Pa

< 1055 Pa