Edwards Signaling 5510M User Manual

Description and operation, Electrical specifications, Specifications

P/N 3100359 ISSUE 2 © 2002

Installation Instructions for Adaptatone Millennium

Remote Audio Signal Converter Series 5510M

Description and Operation

Description and Operation

Description and Operation

Description and Operation

Description and Operation

Edwards Remote Audio Signal Converter is intended for

industrial applications where high audible output and

microcomputer reliability are required.

Catalog Series 5510M are UL and cUL Listed as Audible

Signal Appliances for use in the following hazardous

locations.

Electrical Specifications

Electrical Specifications

Electrical Specifications

Electrical Specifications

Electrical Specifications

Current (A)

Voltage

Standby

Tone On

Remote Audio Signal Converter

125V DC*

0.10

0.21

250V DC*

0.02

0.10

120V AC 50/60 Hz

0.10

0.32

240V AC 50/60 Hz

0.10

0.20

CHESHIRE, CT 203-699-3300 FAX 203-699-3365 (CUST. SERV.) 203-699-3078 (TECH SERV.)

The Audio Signal Converter operates from local power.

The 5510M-25Y6 converts 25V RMS audio signal to 10V

RMS for use with the 5532M Adaptatone Speaker/Ampli-

fiers. The 5510M-70Y6 converts a 70V RMS audio signal

to 10V RMS for use with the Edwards 5532M Adaptatone

Speaker/Amplifiers or other 10V RMS applications.

Catalog

Hazardous

Temp.

Number

Locations

Code

5510M-25Y6

Class I, Div. 2, Groups A, B, C, D

T4 (135C)

5510M-70Y6

Class II, Div. 2, Groups F, G

T5 (100C)

Class III, Div. 1 and 2

Specifications

Specifications

Specifications

Specifications

Specifications

Weight ................................................... 6 Pounds (2.7 kg)

Hazardous Locations, UL Standard UL1604

Ambient Temp. ................... +41F to +104F (+5C to +40C)

Non-Hazardous Locations

Variable Ambient Temp. ..... -40F to +151F (-40C to +66C)

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

During installation, care must be taken so that components

on the printed circuit board are not damaged.

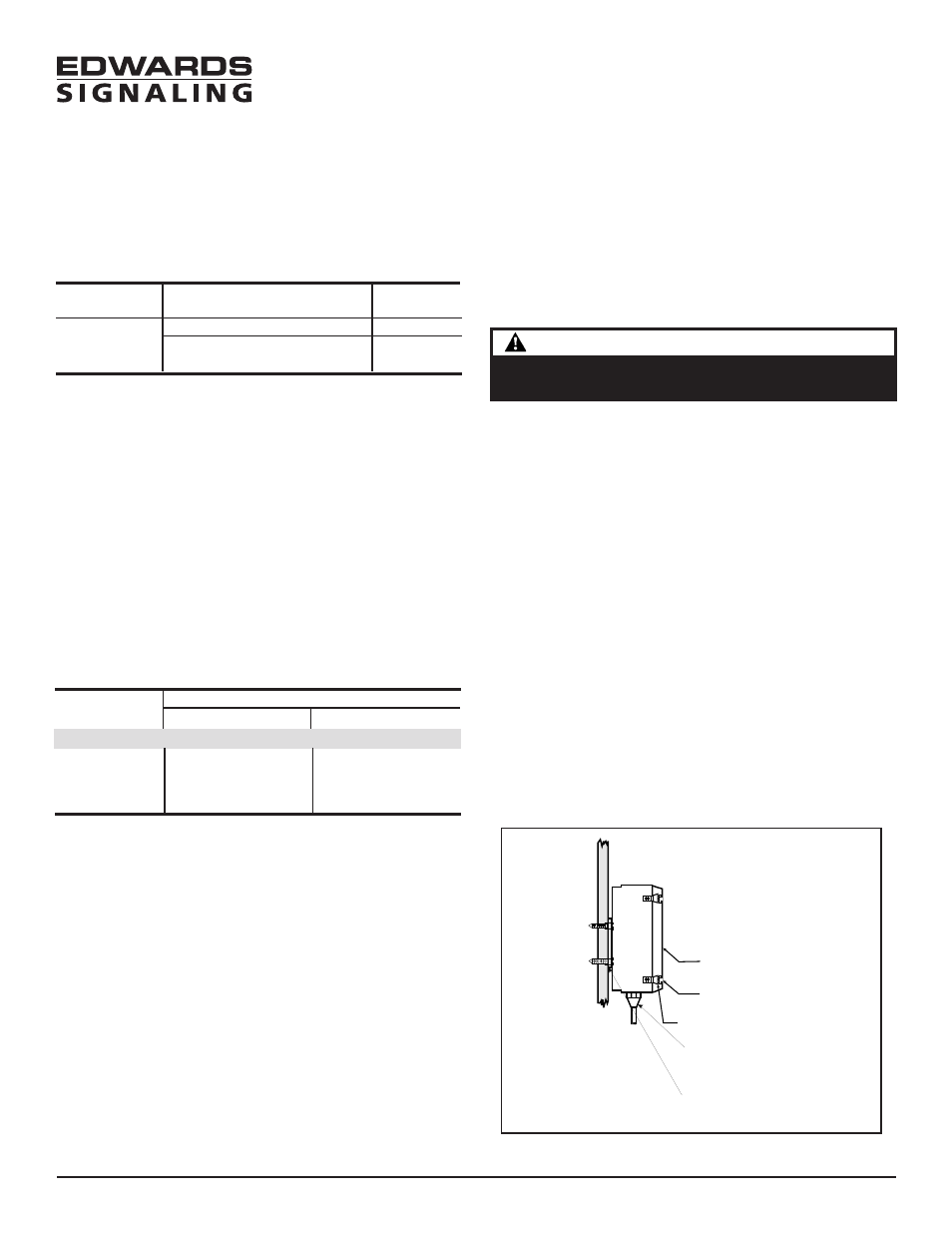

1. Mount Adaptatone as shown in Figure 1.

a. Flat Surface Mounting. Secure unit to

mounting surface using the (4) mounting holes in

the mounting plate on the rear of the box. Use

the #10 x 3" (76 mm) wood screws (furnished loose)

or other hardware (not supplied) suitable for the

mounting surface.

b. Rigid Pipe Mounting. Loosen the (4) cover screws

from the signal box and lift off signal box cover.

NOTE: Cover screws are captive. Do not remove from

cover.

Remove the center knockout in lower wall of box

and mount box to a 1/2" (12.7 mm) conduit pipe

using suitable connector.

2. Install wires through a knockout hole in the bottom

of the box from a raceway that is, with its connections

to the 1/2" (12.7 mm) conduit knockout hole, approved

for the same degree of protection and enclosure type

needed by the application. Use the provided plastic

tie-wrap, on the barrier to the electronics, to separate

incoming power leads from signal and tone initiating

leads, per NEC (Figures 4, 5 and 6).

Installation

Installation

Installation

Installation

Installation

The Adaptatone may be mounted to any flat surface or

may be used as a freestanding unit mounted to a rigid

pipe. The Adaptatone must be installed in accordance

with the latest edition of the National Electrical Code or

other regulations applicable to the country and locality

of installation and by a trained and qualified electrician.

NOTE: The increased resistance due to long wire runs

needs to be accounted for in sizing wire.

Consult Applications Engineering for details.

Figure 1. Adaptatone Mounting

Signal Box

(4) Cover

screws

(4) Collar

gaskets

Raceway and connections

(not supplied)

to the 1/2" (12.7 mm)

knockout hole

(4) #10 x 3" (76 mm)

screws or other hardware

suitable for the mounting surface