Maintenance, Mounting: plate & alarm, Checkout & troubleshooting – Edwards Signaling 517TCSB User Manual

Page 5

Wire used for interconnecting shall be in accordance with the latest edi-

tions of article 760 of the National Electrical Code (NFPA 70) and must not

exceed a resistance of 10 ohms.

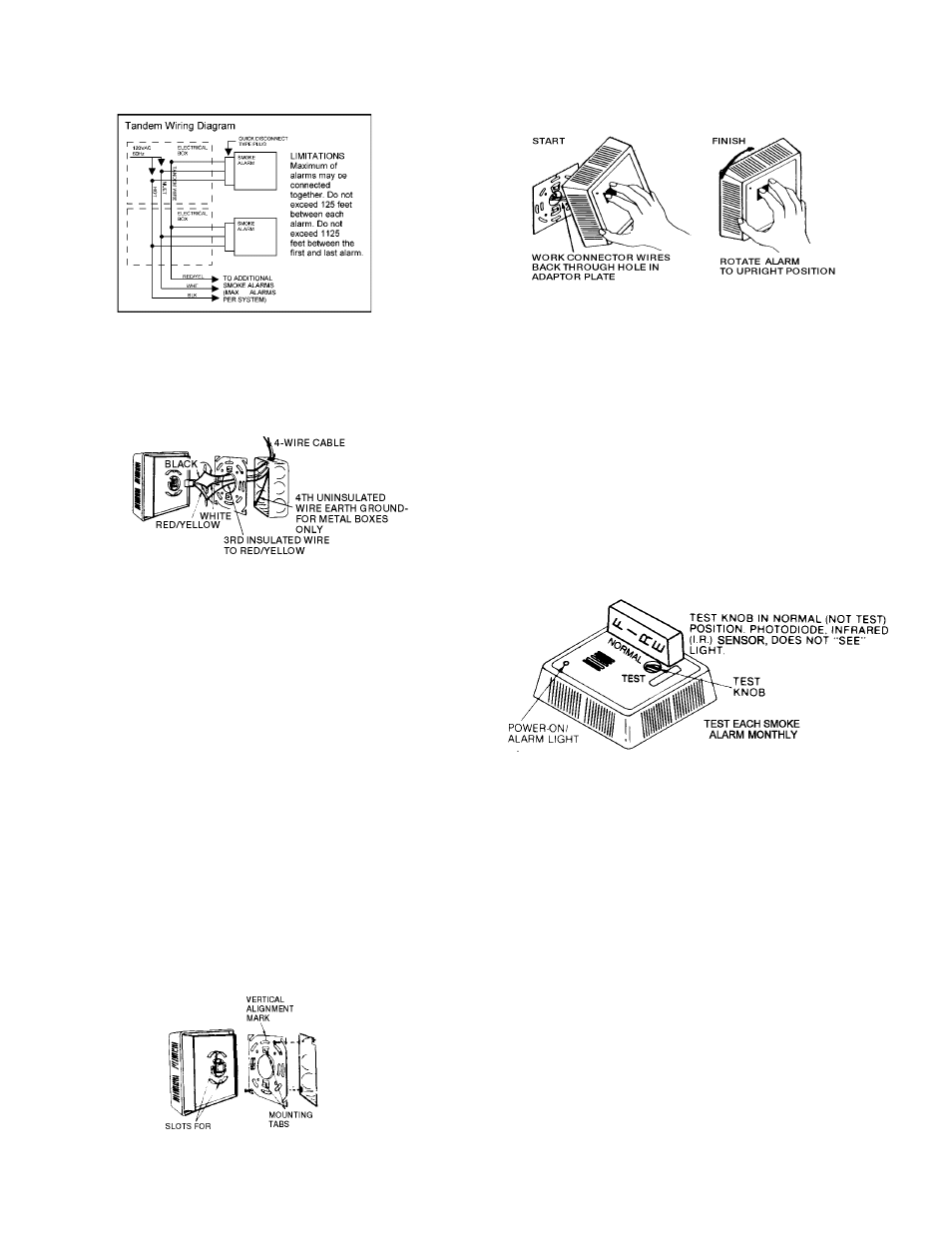

3. Place the alarm up to the mounting plate, rotating it clockwise until alarm

firmly snap locks into place. Keep the alarm parallel to the mounting plate

so upper and lower tabs on the plate seat correctly into the alarm.

6

6

1.

Run a minimum of 16 gauge, 3-conductor cable, plus ground (4 wires) to

the first alarm junction box from a power supply and between all alarms

that are to be connected together. Use UL Listed Class 1 wire.

2.

Make wire connections to the supplied plug-in connector as follows: black

to black, white to white, 3rd conductor to the red/yellow wire. The red/

yellow wire should be stripped to make the connection. Connect ground

wire between metal outlet boxes.

c. To test alarm for high sensitivity, turn test knob clockwise to TEST 2

position. Alarm should remain silent.

d. Make sure to return test knob back to its normal position.

e. If your alarm sounds during this test it means the alarm's senstivity

has become too high and may cause false alarms.

f.

This could mean your alarm is dirty and should be cleaned as de-

scribed in the maintenance procedure below.

g. To check for proper smoke entry into your alarm's sensing chamber,

Edwards recommends using the Home Safeguard Smoke Alarm

spray. This test should be performed once a year and should be

sprayed from a distance no closer than 12 inches from the smoke

alarm.

MAINTENANCE

After your alarm has been in operation for a period of time or if it was in-

stalled prior to the completion of all building construction, your alarm may have

become more sensitive due to dirt build-up in the alarms optic sensing cham-

ber which could cause nuisance alarms or could cause activation from small

amounts of smoke build-up.

If this should occur, following this simple washing procedure will restore

your smoke alarm back to its original condition.

For further information, regarding frequency of cleaning and testing, refer to

NFPA 72, NFPA, Batterymarch Park, Quincy, MA 02269.

NOTES ON TANDEM INTERCONNECTING MODELS

· Only model 517TB, 517THB and 517TCB may be connected. DO NOT

connect Edwards Smoke Alarms to other manufacturer's smoke alarms.

· No more than 12 Edwards models 517TB and 517THB may be connected

in tandem.

· No more than 6 Edwards models 517TCSB, 517TCB and 517TC may be

connected in tandem.

· All units connected in tandem MUST get their power from the same circuit,

that is, all smoke alarms in tandem must be controlled by the same fuse or

circuit breaker.

· After installation to verify proper working conditions all horns must sound in

this system.

IMPORTANT WARNING:

Failure to observe any of the conditions set forth may cause system mal-

function and damage to the alarm.

MOUNTING: PLATE & ALARM

1. Lace the connector through the provided mounting plate and secure the

plate to the junction box so that the smoke alarm snap-in tabs are in the

vertical position if wall mounted.

NOTE: Mounting plate is marked "THIS SIDE OUT" and slotted for proper

positioning.

2. Plug the wire connector into the alarm base.

CHECKOUT & TROUBLESHOOTING

1. Turn test knob to the NORMAL position and supply house power to the

alarm. The red indicator light should flash every 15-30 seconds, showing

that the alarm is operating properly.

2. If red light is not flashing or the green LED is not on:

a. Check that the battery is installed.

b. Check to see if the 120V AC is connected.

c. If the power and wiring check out, but the red light does not flash or

the green LED is still off, return the alarm to the manufacturer.

3. Testing with the Test Knob:

a. Rotate the test knob counter-clockwise to the TEST 1 position and

wait up to 20 seconds for the alarm to sound. If the alarm does not

sound after 20 seconds, return the alarm for service.

b. After successfully testing alarm, return test knob to NORMAL (non-

test) position and wait 20 seconds for the alarm to stop sounding.