Maintenance, Cleaning the detector, Test – Edwards Signaling E-PD User Manual

Page 2: Specifications, Certification and compliance, Contact information

2 / 2

P/N 3101207 • REV 03 • REB 28JAN13

Maintenance

Cleaning the detector

When cleaning is necessary, the sensing chamber of the

detector unsnaps for easy field cleaning and service.

To clean the detector:

1. Remove the detector from the base.

2. Insert a screwdriver in the small slot where the detector

cap connects to the detector body. See Figure 3.

3. Pry the detector cap off the detector body.

4. Squeeze the optical block chamber where the two arrows

point, labeled “squeeze here.”

5. Pull off the optical block chamber.

6. Blow off the optical block base in the detector body using

clean compressed air.

7. Snap a new optical block chamber in place. Make sure

you line up the two arrows on the block chamber with the

snaps on the optical block base.

8. Connect the detector cap to the detector body by rotating

the cap clockwise until it snaps into a locked position.

9. Install the detector onto the base.

Note:

To verify the effectiveness of the cleaning,

recalibrate the device and run a device maintenance

report. Refer to the technical reference manual.

10. Test the detector and verify sensitivity.

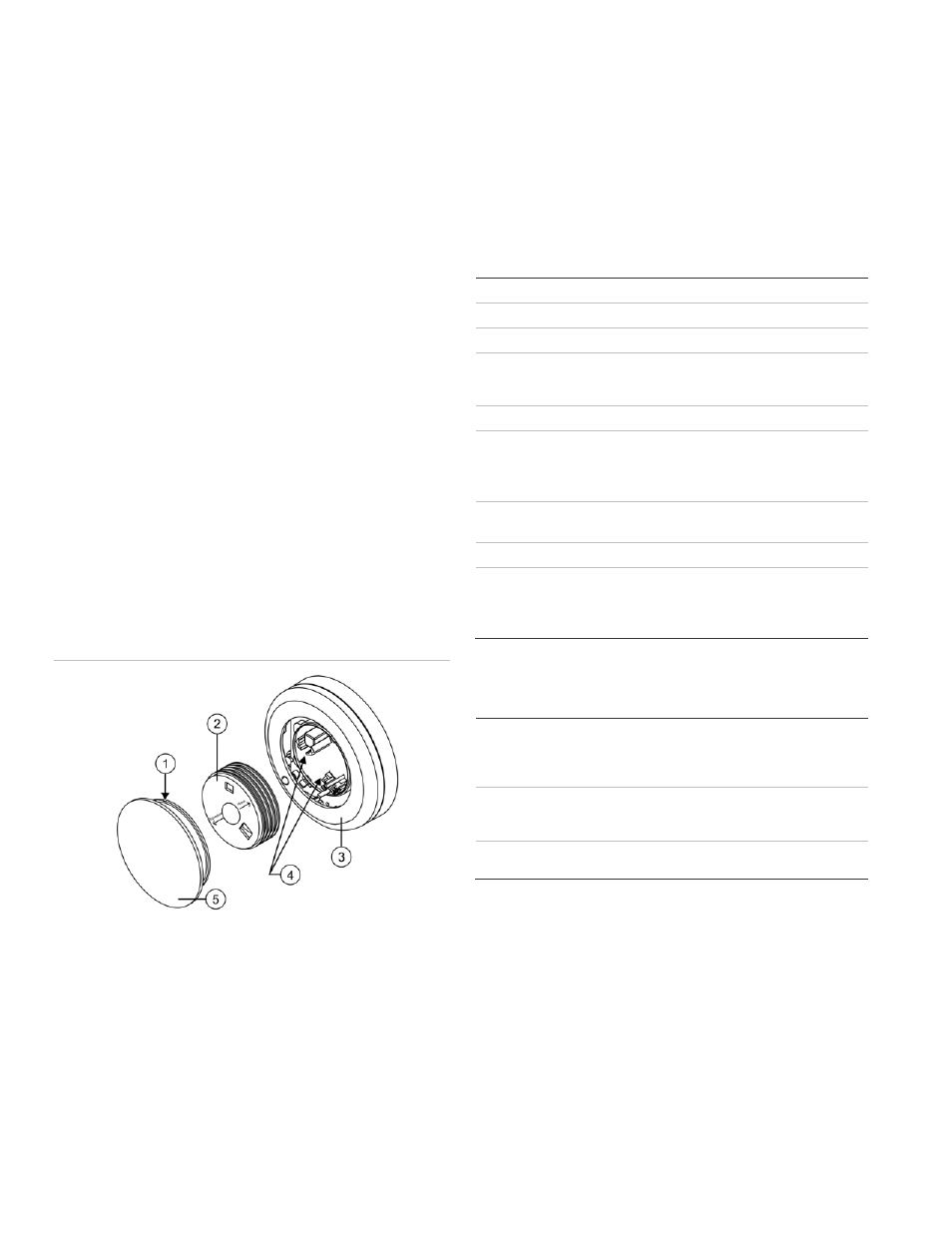

Figure 3: Detector disassembly

1.

Slot to insert screwdriver

2.

Optical block chamber

3.

Detector body

4.

Optical block base

5.

Detector cap

Test

NFPA 72 and CAN/ULC-S537 require a calibrated sensitivity

test upon completion of the original installation and following

any modifications or additions to the system. The detector can

perform this test and generate a system sensitivity report.

To test the detector:

1. Before initial testing, remove the dust cover from the

detector and notify the proper authorities that the fire

alarm system is undergoing maintenance and will be

temporarily out of service.

2. Test the detector using Smoke-In-A-Can (model SM-200)

canned smoke. Carefully follow directions on the can to

avoid damage to the detector.

Specifications

Communication line voltage

Maximum 20 V peak-to-peak

Normal operating current

45 µA

Alarm current

45 µA

Smoke sensitivity range

UL

ULC

0.67 to 3.66%/ft. obscuration

0.74 to 3.70%/ft. obscuration

Environmental compensation

Automatic

Compatible bases

Standard: B4U, B4U-LP

Relay: RB4U

Isolator: IB4U

Audible: SB4U

Maximum distance from ceiling

wall-mounted

12 in. (305 mm)

Storage temperature

−4 to 140°F (−20 to 60°C)

Operating environment

Temperature

Humidity

32 to 120°F (0 to 49°C)

0 to 93% RH, noncondensing at

90°F (32°C)

Certification and compliance

Manufacturer

Edwards, A Division of UTC Fire & Security

Americas Corporation, Inc.

8985 Town Center Parkway, Bradenton, FL 34202,

USA

Year of

manufacture

The first two digits of the date code (located on the

product identification label) are the year of

manufacture.

North American

standards

Meets: UL 268, ULC-S529-02,

Follow: NFPA 72, and CAN/ULC-S524

Contact information

For contact information, see our Web site:

www. edwardssignaling.com.