Service and maintenance, 1 replacement of plug-in sensor, Replacement of plug-in sensor – Detcon CX-IR User Manual

Page 29: Figure 13 sensor cell and itm mating

Model CX-IR

5. Service and Maintenance

Calibration Frequency

In most applications, monthly to quarterly span calibration intervals will assure reliable detection. With

industrial environments varying, after initial installation and commissioning close frequency tests should be

performed, weekly to monthly. Test results should be recorded and reviewed to determine a suitable

calibration interval.

Visual Inspection

The Sensor should be inspected annually for the following:

• Inspect the sensor for signs of corrosion, pitting, and water damage.

• Remove the Splash Guard and inspected it for blockage, broken, cracked, or missing pieces.

• For H2S Sensor assemblies, inspect CX-IR Series Splashguard Adapter Assembly with integral filter (P/N

602-003803-200) for blockage of filter material.

• Inspect inside of the Junction Box for signs of water accumulation, signs of corrosion.

• Check wiring to ensure there are no loose or pinched wires and all connections are clean and tight.

Condensation Prevention Packet

A moisture condensation packet should be installed in every explosion proof junction box. The packet will

prevent the internal volume of the J-Box from condensing and accumulating moisture due to day-night

humidity changes. This packet provides a critical function and should be replaced annually.

5.1 Replacement of Plug-in Sensor

NOTE

It is not necessary to remove power while changing the plug-in toxic gas sensor in order to

maintain area classification. The sensor is intrinsically safe.

NOTE

Only replace the plug-in sensor with an authorized CX-IR family of gas sensors.

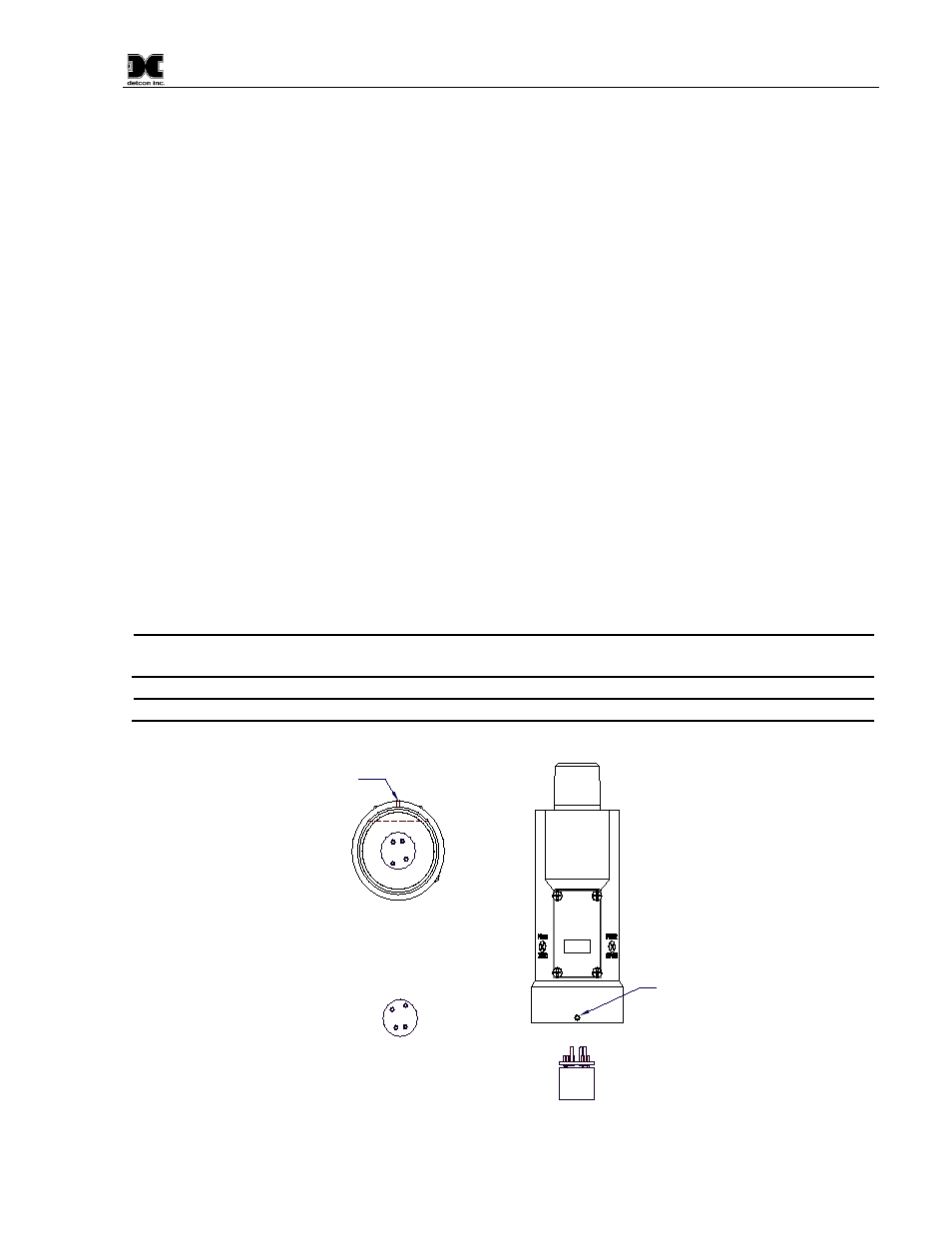

ITM

(Bottom View)

Display

Window

Plug in Sensor

(Bottom view)

Locking

Setscrew

Locking

Setscrew

detcon inc

.

MODEL

CXT-IR

Figure 14 Sensor Cell and ITM Mating

CX-IR Instruction Manual

Rev. 1.2

Page 25 of 34