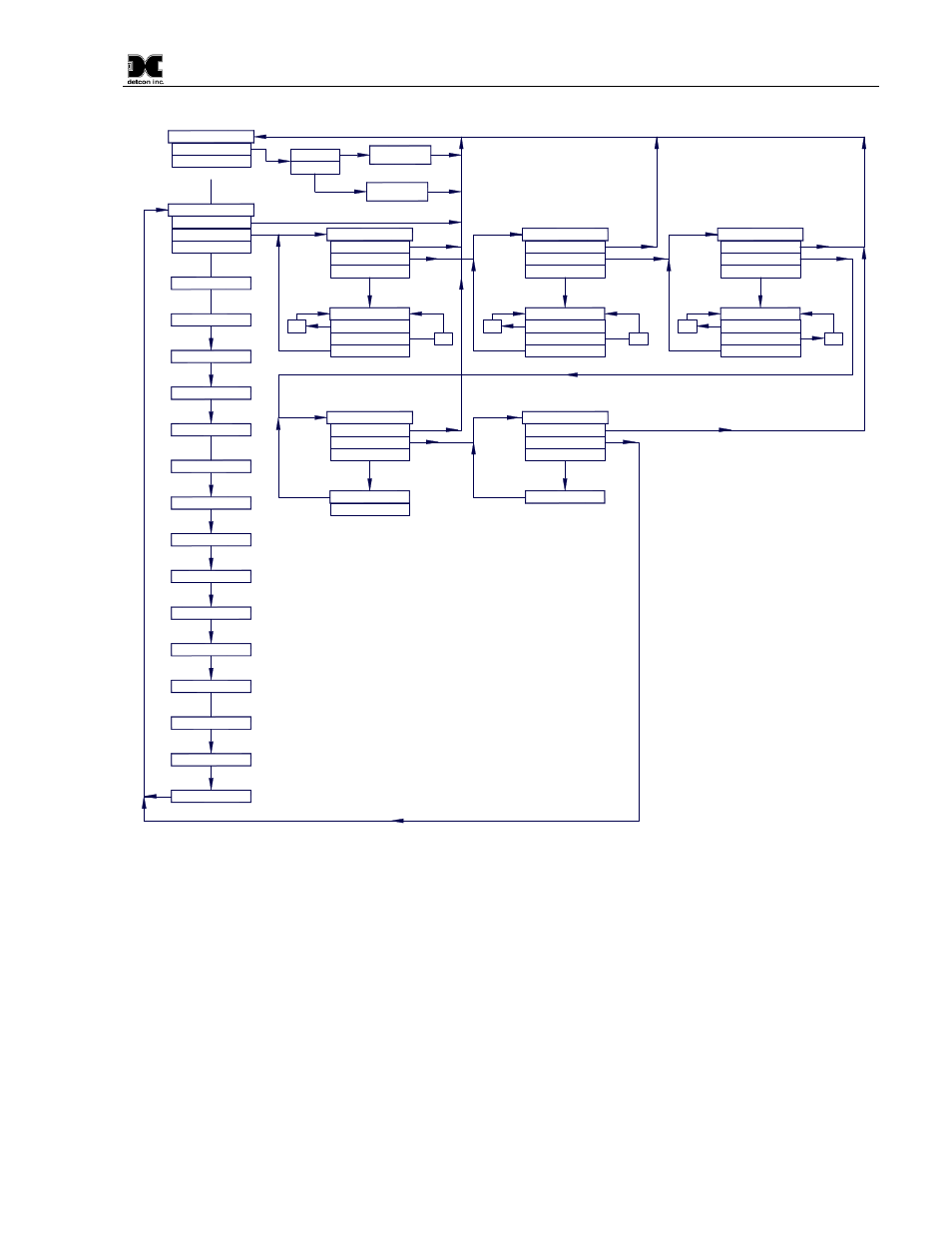

Normal operation, Figure 13 dm-700 software flowchart, 3 normal operation – Detcon DM-700 User Manual

Page 19: Software flowchart

Model DM-700

DM-700 Instruction Manual

Rev. 4.0

Page 15 of 48

Software Flowchart

dec

LEGEND:

PGM1 - Program Switch Location #1

PGM2 - Program Switch Location #2

(S) - Momentary Swipe

(M) - Momentary hold of Magnet during text

scroll until the ">" appears, then release

(3) - 3 second hold from ">" prompt

(10) - 10 second hold from ">" prompt

Auto Time-out - 5 seconds

inc - Increase

dec - Decrease

#, ##, ### - numeric values

PGM1/2 (M)

Raw Current XXX

Gain Setting XXX

Voltage XX.X VDC

Sensor Temp XX C

Bias Voltage XX.XX

Output sign XXX

mA Output XX.XX

AutoSpan @ XX

Sensor Life XXX%

Last Cal XX Days

PGM2 (10)

PGM1/2 (3)

Simulation

AutoZero

PGM1 (3)

PGM2 (10)

PGM2 (3)

Gas Type XXX

Version X.XX

Range XXX ppm

Serial ID XX

inc

Auto Time-Out

View Sensor Status

PGM1/2 (3)

PGM1/2 (M)

Model Type

PGM2 (S)

PGM1/2 (3)

PGM1 (S)

Auto Time-Out

Signal Output Check

##

AutoTime-out

PGM1/2 (3)

PGM1/2 (M)

Set AutoSpan Level

AutoSpan

Normal Operation

PGM1 (3)

PGM1/2 (M)

Defaults Restored

PGM1/2 (3)

Auto Time-Out

Auto Time-Out

Restore Defaults

Auto Time-Out

inc

PGM2 (S)

PGM1/2 (3)

PGM1 (S)

##

PGM1/2 (3)

PGM1/2 (M)

Set Serial ID

dec

inc

PGM1/2 (3)

PGM1 (S)

PGM2 (S)

##

dec

PGM1/2 (3)

PGM1/2 (M)

Set Range

Figure 13 DM-700 Software Flowchart

3.3 Normal Operation

In normal operation, the ITM Display continuously shows the current sensor reading, which will normally

appear as “ 0 ”. Once every 60 seconds the LED display will flash the sensor’s measurement units and gas

type (i.e. ppm H

2

S). If the sensor is actively experiencing any diagnostic faults, a “Fault Detected” message

will scroll across the display on the ITM display once every minute instead of the units of measure and the gas

type. At any time, while the sensor is in “Fault Detected” mode, PGM1 or PGM2 can be swiped to prompt the

sensor to display a list of the active faults.

In normal operation, the 4-20mA current output linearity corresponds with the full-scale range. The RS-485

Modbus™ serial output provides the current gas reading and complete fault status on a continuous basis when

polled by the master device.