Figure 10 sensor wire connections, Table 1 wire gauge vs. distance, Figure 10 – Detcon DM-700 User Manual

Page 14

Model DM-700

DM-700 Instruction Manual

Rev. 4.0

Page 10 of 48

Table 1 Wire Gauge vs. Distance

AWG

Wire Dia.

Meters

Feet

Over-Current

Protection

22

0.723mm

700

2080

3A

20

0.812mm

1120

3350

5A

18

1.024mm

1750

5250

7A

16

1.291mm

2800

8400

10A

14

1.628mm

4480

13,440

20A

NOTE 1: Wiring table is based on stranded tinned copper wire and is designed to serve as a

reference only.

NOTE 2: Shielded cable is required for installations where cable trays or conduit runs include

high voltage lines or other possible sources of induced interference. Separate conduit runs are

highly recommended in these cases.

NOTE 3: The supply of power should be from an isolated source with over-current protection

as stipulated in table.

Terminal Connections

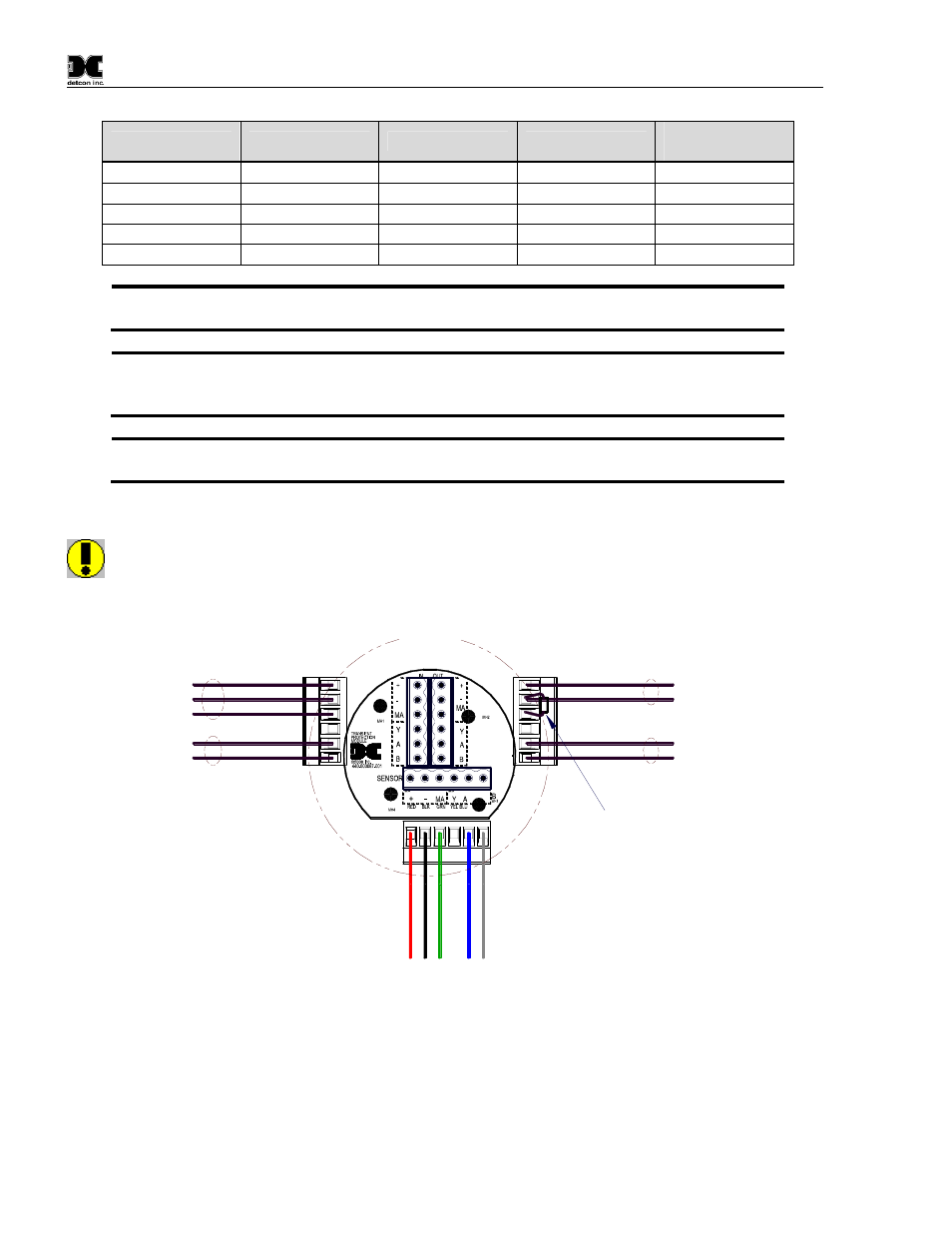

CAUTION: Do not apply System power to the sensor until all wiring is properly terminated. Refer to

Section 2.7 Initial Start Up

Customer

Supplied Wiring

(Out to next Device)

(+

)

m

A

(-

)

A

(+

)

B

(-

)

Wiring to

Sensor Assembly

W

h

t

B

lu

R

e

d

G

rn

B

lk

Explosion

Proof

Junction Box

(+)

mA

(-)

A(+)

B(-)

(+)

mA

(-)

A(+)

B(-)

Customer

Supplied Wiring (In)

Modbus RS-485 to

Host Control Device

Power from and 4-20mA

out to Control Device

Install a 100-250 Ohm

resistor if the 4-20mA

output is not used

Modbus RS-485 to

next Device

Figure 10 Sensor Wire Connections

a) Remove the junction box cover. Identify the terminal blocks for customer wire connections.

b) Observing correct polarity, terminate the 3-conductor 4-20mA field wiring (+, -, mA) to the sensor

assembly wiring in accordance with the detail shown in Figure 10. If the 4-20mA output is not used,

install a 100-250Ω resistor between the mA and (-) terminals on the Transient Protection Module.