LumaSense Technologies M67 User Manual

Page 42

M67, M67S Manual

41

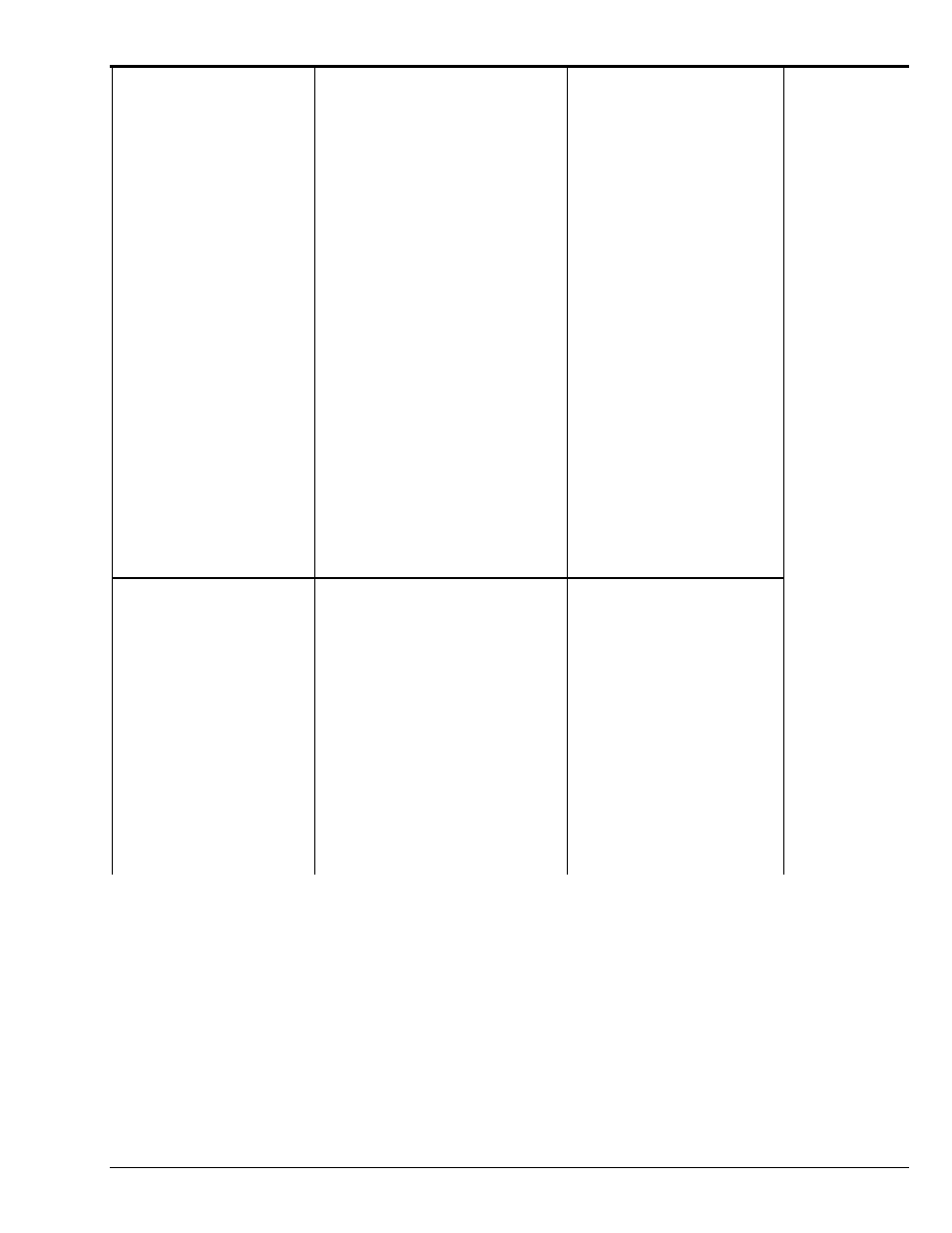

Target moves partially out of field of

view. Conveyor type applications will

cause fluctuations as target passes by the

field of view.

Application may require “Peak

Picker”. Consult LumaSense.

Target may be changing temperature

rapidly (Thermocouple does not respond

as fast as the Infraducer).

Speed of response can be slowed

down to maximum of 10 seconds

for 95% of reading.

Loose connection in wiring.

Electrical noise in lead wires caused by

intense magnetic fields. Improper

selection of inter-connecting cable.

Cable run in same conduit as AC power

lines.

See Section 8

Improper grounding of cable shield

and/or Infraducer housing and other

instrument on same current loop.

See Section 8

Flame or reflection of flame may be

entering the field of view.

Long sight tube may be needed.

Block reflection with shield.

Steam, smoke, thick dust, Personnel,

moving machinery intermittently

blocking optical path of the Infraducer.

Non-uniform emissivity of large,

moving targets.

Slower response is required.

Emissivity setting too low. Do not set

below 10%. With low emissivity targets,

minute reflections can cause

interference. Remember 10% emissivity

means 90% reflection.

Shield response speed is required.

Slower response speed required

for “average” reading.

Loose connection inside Infraducer.

Open from rear and inspect for

loose or broken wires.

Faulty Instrument.

Consult LumaSense.

Slow fluctuations from very

low to very high readings.

Ambient temperature of Infraducer

changing too fast for compensating

network.

Insulate Infraducer from ambient

temperature changes. Use plain or

water cooled jacket.

Coolant to cooling jacket was just

turned on or off. Coolant temperature

varies too much to be reliable. Coolant

flow not constant.

Allow 1 hour for stabilization

after coolant flow begins. Assure

constant flow 24 hours a day.

Insufficient warm-up time (for

electronics).

Allow 1/2 hour for stabilization.

Infraducer housing has just been

installed for 10 minutes or longer.

Infraducer temperature changing

too fast for compensating network

to keep up after holding in hands.

Allow 1/2 hour for stabilization.

Reflected energy may be entering

Infraducer.

See 6.4

Lens or window clouding up (coolant

below air dew point temperature).

Increase air purge rate and/or

check air dew point and coolant

temperature. Ensure air is dry.