LumaSense Technologies M67 User Manual

Page 23

M67, M67S Manual

22

Figure 15 - Protective Jacket With Screw On End Cover

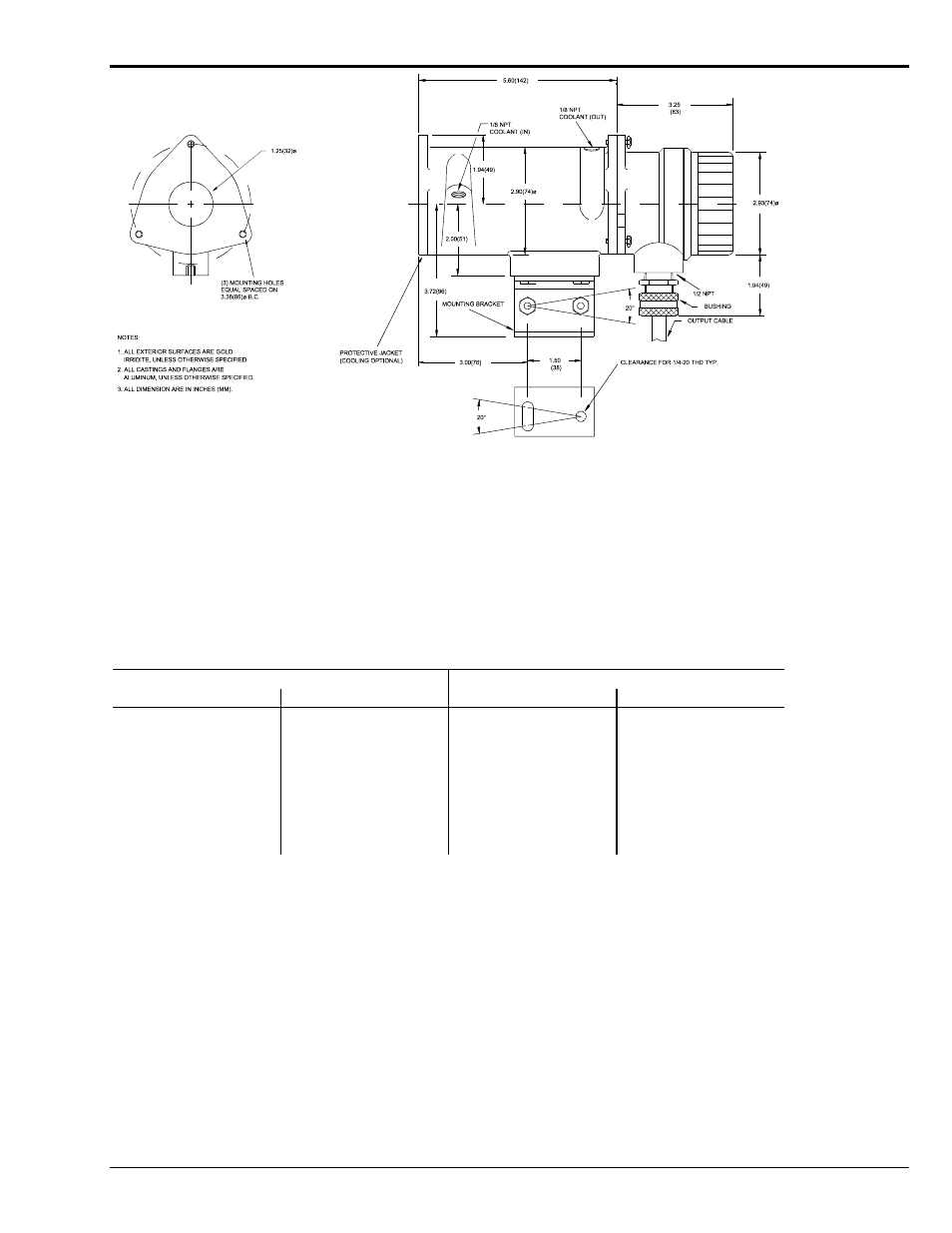

7.4 PROTECTIVE JACKET WITH OPTIONAL COOLING CAPABILITY

The coolant may be connected to the INFRADUCER jacket using a 1/4" O.D. tubing. Connections are made using two 1/8"

NPT x 1/4" O.D. tube fittings. See Figure 16. (If /XPD6HQVH’s type “N” Air Purge Assembly is included, see Figure 17).

The coolant may be tap water or, preferably, recycled water suitably treated to prevent corrosion. Diethylene glycol based anti-

freeze may also be used in a closed circuit cooling system.

The following table shows the minimum coolant circulation rate for a supply temperature of 60°F (20°C).

MINIMUM COOLANT CIRCULATION RATE

Ambient Temperature

Coolant Circulation

°F

°C

Gal/hr

Liters/hr

150

65

0.2

0.8

200

95

0.6

2.3

250

100

1.0

3.8

300

150

2.0

7.6

350

175

3.0

11.4

400

205

4.0

15.2

450

230

6.0

22.7

500

260

10.0

37.8

CAUTION

Coolant supply temperature must be above dew point of the air around the INFRADUCER to avoid

erroneous readings.

A major advantage of the protective/cooling jacket is that, once installed, it permits the rapid removable and replacement of the

INFRADUCER without disturbing the alignment on the target. Removal and replacement can be done in less than one minute.

Electrical wiring connection and return to service can be accomplished within 2 to 5 minutes. (Note the warning regarding

method of removal shown in Figure 16).

CAUTION

For low temperature range start-ups, please observe the precautions listed in Section 10.1, page 35.