4 cool timer stage operation – Hired-Hand Farm Hand Series: Vent Master 16 Stage User Manual

Page 21

Part No. 4801-5098 Farm Hand Vent Master 18

the Tunnel On Stage (SWX-2) switch to off. You can then set the temperature at which you

would like to enter tunnel mode at P25 and the temperature at which you would like to exit

tunnel mode at P26. Otherwise, set the Tunnel On Stage (SWX-2) to ON.

12.4 Cool Timer Stage Operation

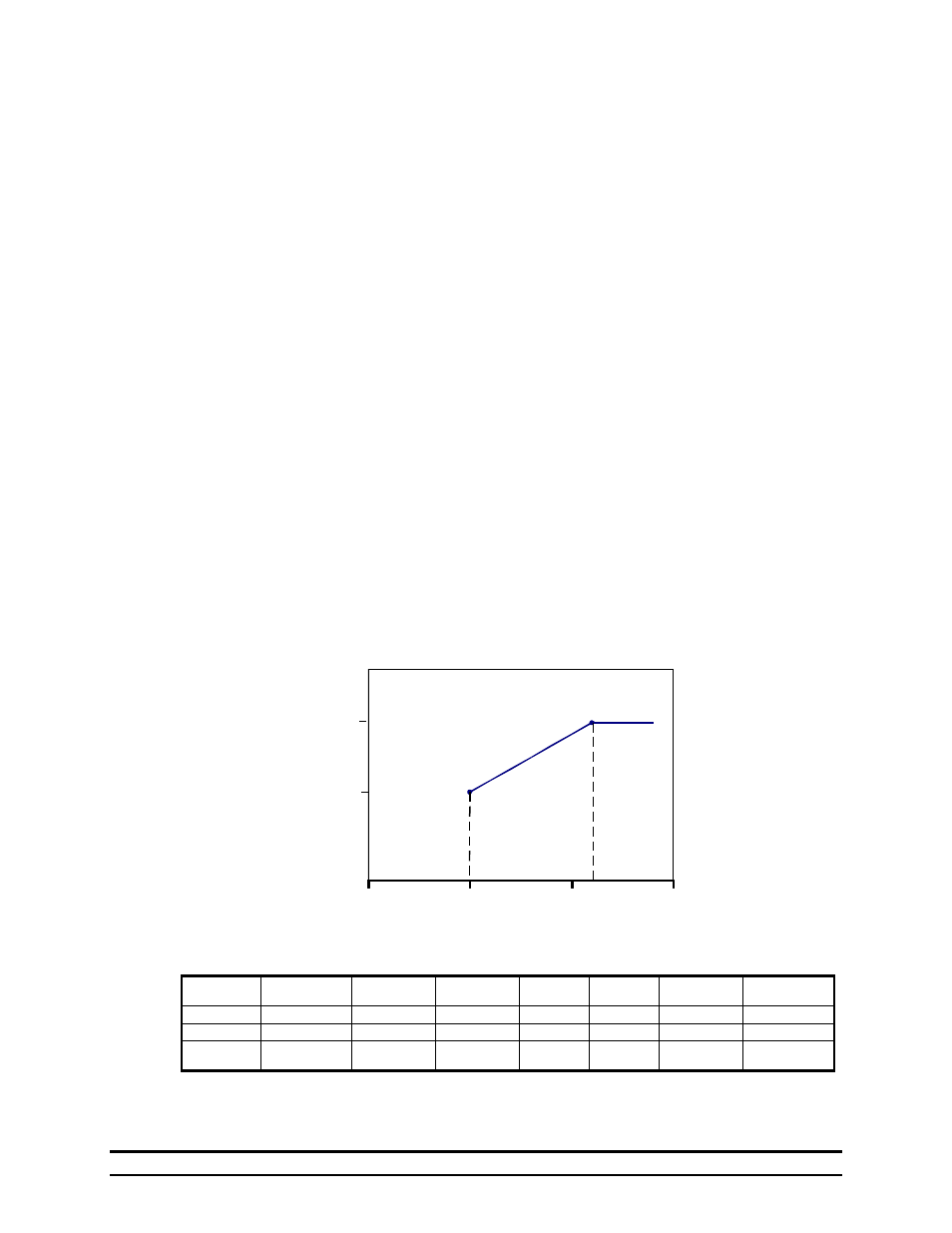

On the Farm Hand Vent Master any of the ON/OFF can be placed on a cool timer. A cool timer

stage will come on and run at the timer percentage whenever temperature is above it’s OffPoint

(Off), and its timer percentage will increase as temperature rises. The following graph shows

how you can vary this percentage.

Refer to Graph 1 and Table 1. The stage is placed on a cool timer by setting P3=2. A Cool

Timer stage always varies its runtime based on the stage's temperature and its ON and OFF

settings. In this example, the OffPoint is set to 80ºF (OFF=80), and the OnPoint is set to 86ºF

(ON=86). The stage will not run if the temperature is below the OffPoint, as shown in

Graph 1. When the temperature reaches the OffPoint, the stage is placed on the system timer.

To enhance temperature control, the Runtime percentage of a cool timer stage can be varied. The

percentage of the Runtime that the cool timer stage is ON can be varied when the temperature is

between the OffPoint and the OnPoint by setting parameters P70 and P71. In this example, the

Minimum Runtime percentage is 50%, as set by P71 = 50. The Maximum Runtime percentage is

90%, as set by P70 = 90.

When the temperature reaches 80º F the stage runs for 50% of the Runtime period (2-1/2 minutes

if the system timer is set for 5 minutes, or 5 minutes if the system timer is set for 10 minutes).

As the temperature increases, the Runtime percentage of the stage progressively increases up to

the Maximum Runtime percentage of 90% when the temperature reaches 86º F. Above 86ºF, the

Runtime percentage remains constant at 90%.

Table 1 Example Of Cool Timer Stage Operation

Brief Description Of Cool Timer Stage Operation

Setting

Stage Sensor

Stage Mode

Stage Timer

OffPoint

OnPoint

Cool Timer

Max %

Cool Timer

Min %

Parameter

P1

P2

P3

OFF

ON

P70

P71

Value

10

02

02

80

86

90

50

Option

Sensor 1

Cool Stir

Timer ON

Minimum

OnPoint

Maximum

OnPoint

Maximum

Runtime %

Minimum

Runtime %

75

80

85

90

Runtime Perc

entage

Graph 1 ON/Off Stages

86ºF

OnPoint

90

50

80º F

OffPoint

Temperature (F)